The Invisible "Eyes" of the Packaging Line

Is Your Machine Troubled by These "Visual" Problems?

As your automation component partner, we are dedicated to solving these seemingly minor yet impactful problems. A high-performance photoelectric sensor can dramatically enhance the intelligence, speed, and stability of your packaging machinery.

Problem 1: Unstable Color Mark Recognition on Packaging Film

- Our color mark sensors have built-in Red, Green, and Blue (RGB) LED light sources. During setup, the sensor automatically selects the light source color that provides the strongest contrast between the mark and the background, ensuring stable, reliable detection across a wide range of film designs.

- It features a one-touch “Auto-Teach” function. An operator simply points the sensor’s light spot at the color mark and then the background, pressing the button once for each. The sensor automatically learns the optimal settings, completing the setup in seconds, not minutes.

Problem 2: Failure to Detect Transparent or Highly Reflective Objects

- For Highly Reflective Objects: We offer Polarized Retro-reflective sensors. These use special polarizing filters on the emitter and receiver to 100% distinguish between the “valid” light returning from the reflector and the “false” specular glare from the object’s surface, achieving flawless detection of cans, foil pouches, and glossy boxes.

- For Transparent Objects: We recommend Background Suppression (BGS) or specialized retro-reflective sensors for clear objects. BGS sensors use triangulation to detect anything that enters a precise sensing field, regardless of transparency. Clear object sensors use low-hysteresis circuits to detect minute changes in light intensity.

Problem 3: Sensor Malfunctions Due to Dust, Moisture, or Ambient Light

- Our sensors feature robust metal or high-strength plastic housings sealed to an IP67 protection rating. This makes them completely dust-tight and capable of withstanding high-pressure washdowns.

- They use high-power LED light sources and high-sensitivity receivers, providing huge signal redundancy. This ensures reliable detection even if the lens becomes partially obscured. Advanced synchronous detection technology effectively filters out interference from factory lighting and other sources.

Problem 4: Response Speed Can’t Keep Up with High-Speed Lines

- Using dedicated high-speed processing chips and optimized circuit design, our sensors achieve ultra-fast response times of less than 1 millisecond (ms), with specialized models reaching as low as 50 microseconds (μs). This is more than sufficient for the most demanding high-speed applications in the packaging industry, ensuring every single object is accurately captured.

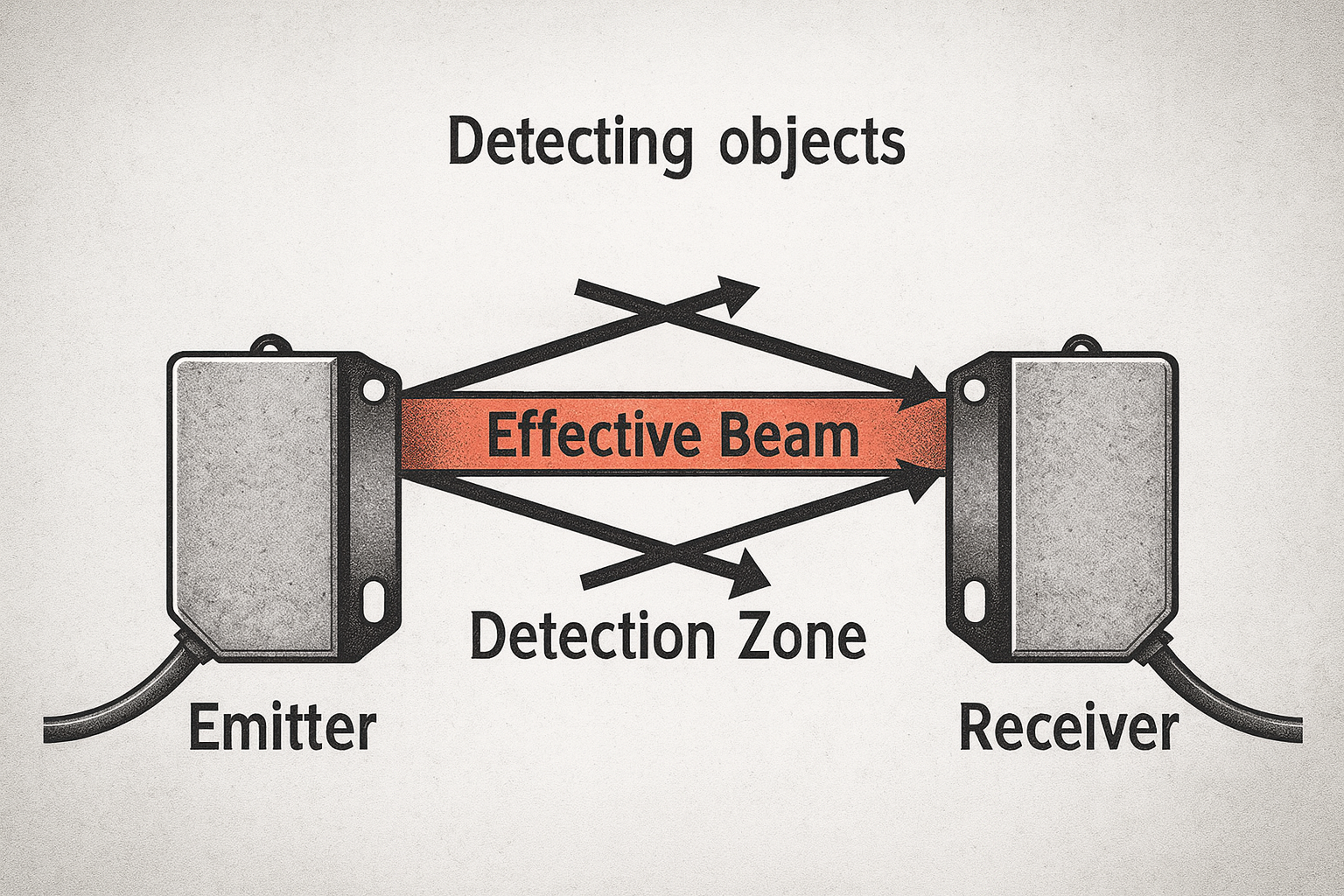

How Does a Photoelectric Sensor Work?

A photoelectric sensor operates on the principle of light beam interruption or reflection. Here’s how it works:

- Emitter sends a beam of infrared or visible light.

- Receiver detects the beam.

- When an object interrupts or reflects the beam, the sensor detects a change in light.

- The sensor then triggers an electrical signal to the control system (PLC or controller).

Types of Photoelectric Sensors:

| Type | Description | Use Case |

|---|---|---|

| Through-Beam (Opposed) | Emitter and receiver are separate; beam is blocked by the target | Long distances, high reliability |

| Retroreflective | Emitter and receiver in one housing; uses reflector | Easy setup, general object detection |

| Diffuse Reflective | Light reflects directly off the object to the receiver | Short-range detection, transparent objects |

Key Features and Specifications

| Specification | Typical Value |

| Sensor Type | Through-beam Photoelectric Sensor |

| Detection Range | Up to 20+ meters |

| Light Source | Infrared LED (940nm) |

| Supply Voltage | 10-30 VDC |

| Response Time | < 1ms |

| Output Type | PNP/NPN (selectable) |

| Protection Rating | IP67 |

| Operating Temperature | -30°C to +60°C |

| Housing Material | Metal (brass/stainless steel) |

| Connection | Cable or connector options |

Applications of Photoelectric Sensors

Photoelectric sensors are essential in modern industrial automation due to their speed and versatility.

Industrial Automation

- Detecting parts on assembly lines

- Positioning and alignment

- Presence/absence sensing

Photo Eye Sensor for Conveyor

- Detect packages on moving belts

- Trigger diverters and sorters

- Count products in real time

Packaging & Labeling Systems

- Verify presence of labels

- Detect transparent or irregular-shaped packaging

- Trigger label application mechanisms

Food, Beverage & Pharmaceuticals

- Hygienic non-contact sensing

- Detect bottle fill levels

- Identify caps, seals, or missing components

Safety & Security

- Create optical safety barriers

- Monitor entry/exit points in restricted zones

Advantages of Photoelectric Sensors

1. Non-Contact Detection

•No physical wear or mechanical failure

2. High Precision and Speed

•Microsecond response times for high-speed applications

•Wide range of detectable materials and surfaces

4. Cost-Effective Solution

•Lower total cost of ownership compared to alternatives

Installation and Technical Tips

- Alignment is Key: For through-beam and retro-reflective types, the status indicator on the sensor is your best tool. The signal is strongest when the indicator is brightest or most stable.

- NPN vs. PNP Output: This is critical for PLC compatibility. PNP (sourcing) is the standard in Europe/North America (Siemens, Rockwell). NPN (sinking) is the standard in Asia (Mitsubishi, Omron). Ensure you select the correct type for your control system.

- Light-On vs. Dark-On: This is a logic setting. Light-On (L.O.) means the output is active when the sensor sees the light. Dark-On (D.O.) means the output is active when the light is blocked. Most of our sensors have a simple switch or wire to select the mode.

- Photoelectric Sensor Selection Guide

Choosing the right sensing technology is the first and most critical step. This guide will help you select the perfect sensor for your machine’s application.

Sensor Type | Working Principle | Best For | Avoid When |

Through-Beam | Emitter & receiver are separate. Object blocks the beam. | Long distances, harsh environments, precise position detection. The most reliable method. | Applications where mounting on two sides is impossible. |

Retro-Reflective | Emitter & receiver in one housing. Object blocks beam reflected from a prism reflector. | General-purpose object detection on conveyors. Simpler wiring than through-beam. | Detecting highly reflective, mirror-like objects (use Polarized instead). |

Polarized Retro-Reflective | A retro-reflective sensor with polarizing filters. | Detecting highly reflective objects like cans, foil bags, or shrink-wrapped pallets. | Standard applications where cost is the primary driver. |

Diffuse | Emitter & receiver in one housing. Detects light reflected directly off the object. | Simple presence detection of opaque objects at close range. Lowest cost. | Objects have varying colors, surface finishes, or are not at a fixed distance. |

Background Suppression (BGS) | An advanced diffuse sensor that only detects objects within a precise, set distance. | Detecting objects of different colors against a varied background. Excellent for presence detection on a conveyor belt. | Applications requiring a long detection range. |

Color Mark Sensor | Uses an RGB light source to detect contrast between a printed mark and the background film. | Packaging film registration on VFFS and HFFS machines. | General object detection. |

Related Product

Ready to integrate photoelectric sensors into your system?

Contact us now for a custom quote, bulk pricing, or help choosing the right sensor for your application.

📧 Email: info@fill-package.com

📞 Phone: +8613536680274

🌐 Website: www.fill-package.com

Photoelectric sensors are used to detect the presence, absence, or distance of objects using light beams. They’re commonly found in automation, conveyors, and packaging lines.

They emit a beam of light and detect objects when the beam is interrupted or reflected to the receiver.

Three main types: Through-beam, Retroreflective, and Diffuse Reflective.

A photo eye sensor detects items moving along the conveyor, triggering sorting or counting functions in automation systems.

Non-contact detection, fast response, high precision, and long sensing distances.

Affected by dirt, requires alignment, and can be sensitive to reflective surfaces or ambient light.

Yes, especially diffuse sensors with background suppression or specialized models.

Most sensors are plug-and-play, but sensitivity and alignment may need adjustment depending on the application.