VFFS Sealing & Cutting Blade | Replacement Packing Blade

Sealing Blade Key Features

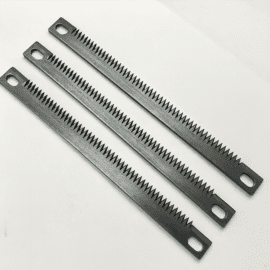

- Optimized Wave Teeth: Delivers a smooth, clean cut, a key function of a quality sealing blade assembly.

- Premium High-Carbon Steel: This packing blade is specially heat-treated for high hardness and superior wear resistance, lasting much longer than standard knives.

- High-Precision Grinding: The cutting edge is extremely sharp, reducing resistance for higher efficiency.

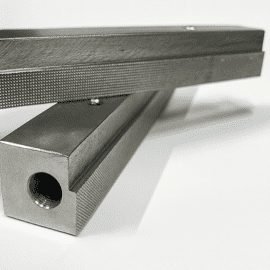

- T-Slot Rail Design: Allows for quick and easy installation, making it the ideal replacement knife for your VFFS machine.

- Anti-Rust Surface Treatment: Effectively extends the storage and operational life of the cutter blade.

Packing blade Size & Technical Specifications

Parameter | Specification |

Product Type | T-Slot Rail Wave Serrated Packing Blade / Sealing Blade (Cutter) |

Core Material | Premium High-Carbon Steel (with special heat treatment) |

Process | High-precision grinding, anti-rust surface treatment |

Common Sizes | 150mm (for 320 models & common bags) 180mm (for 420 models & wide bags) 220 mm(for 620models & wide bags ) Customized Size |

Customization | Custom lengths for all types of Packaging Machine Knives are available. Contact us! |

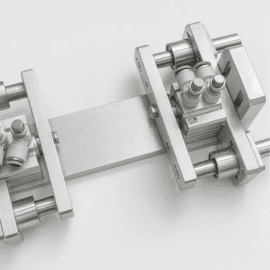

Compatibility

Lifespan & Quality Warranty

Lifespan

Quality Warranty

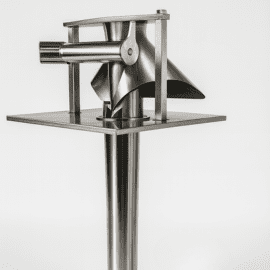

Packing machine cutting blade Installation Guide

Replacing your VFFS cutting blade is simple. Follow these 5 steps:

- A Rigorous Manufacturing Process Forged for Quality

Ever wonder how a simple piece of steel is transformed into the precise, durable cutting tool on your production line? We believe that exceptional quality comes from an unwavering commitment to every detail. We are proud to show you our manufacturing process, so you can see our dedication to quality firsthand.

Step 1: Material Selection & Forging

- Blanking & Forging: We start by selecting only the highest-grade high-carbon steel. Through the forging process, we reshape the steel’s internal crystal structure, making it denser and tougher. This lays a solid foundation for the blade’s durability right from the source.

Step 2: Advanced Heat Treatment

- Quenching, Tempering & Hardening: This is the “soul” of the blade. We employ a complex, multi-stage heat treatment process with precise control over temperature and time. Quenching gives the blade its extreme hardness, while Tempering provides the perfect amount of toughness to prevent it from chipping or breaking during use. This critical step ensures our blades are both wear-resistant and resilient.

Step 3: High-Precision Grinding

- Rough & Fine Grinding: After heat treatment, the blade blank moves to the high-precision grinding stage. Our skilled technicians use a multi-step grinding process to gradually sharpen the edge to perfection while ensuring the blade body has a smooth finish and exact dimensions. The sharpness of every single blade is born here.

Step 4: Dual Quality Control & Packaging

- In-Process & Final Inspection: We have two critical quality control gates. Before grinding, we inspect the semi-finished product for hardness and performance. After fine grinding, we conduct a final inspection for dimensions, sharpness, and appearance. Only products that are 100% qualified proceed to packaging.

- Packaging & Warehousing: Every qualified blade is carefully treated with anti-rust protection and individually packaged to ensure it arrives in your hands in perfect condition.

Related Product

The easiest way is to measure the length of your current blade. Our 180mm model is perfect for 420-type machines, and the 150mm model fits 320-type machines. If you are unsure, simply send us your machine’s brand, model, and a photo of the old blade. Our technical team will provide a precise compatibility check for free.

Our high-carbon steel undergoes a special heat treatment process, giving it a much higher hardness (HRC 62-64) and wear resistance than standard steel. This means our packing blade has a longer service life and stays sharper for longer, reducing your downtime for replacements.

Absolutely! We fully support custom orders. Whether you need a special length, tooth pattern, or mounting hole configuration for your packaging machine knives, just provide a drawing or a sample, and we can tailor-make a blade to your exact specifications.

For cutting standard composite films (like CPP/PE), the average lifespan of one sealing blade cutter is between 6 and 12 months. However, please note that the lifespan may be shorter if you are cutting very thick materials, films with aluminum foil, or running at extremely high speeds.

Not at all! The replacement process is very straightforward. Our T-slot rail design is made for quick and easy changes. All you need is a wrench and our 5-step installation guide. We also provide a detailed video tutorial to ensure you can do it yourself in minutes.