Sliding Gate Guide Rollers | Heavy-Duty Gate Guide Rollers for Industrial Tracks

Precision Movement. Durable Performance. Industrial-Grade Sliding Gate Roller Solutions.

Product Overview-What is Sliding Gate Guide Rollers?

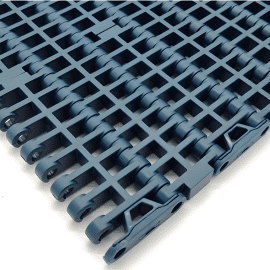

In modern industrial automation and gate control systems, every precise movement matters. As a manufacturer of conveyor accessories and motion components, we proudly introduce our nylon sliding gate guide rollers—engineered to deliver smooth tracking, high durability, and precise alignment for a wide range of industrial applications.

This product combines a high-strength nylon roller body, a precision ball-bearing core, and a standard M10/M12 mounting system to meet the rigorous demands of OEM machine builders and end users alike. It’s a versatile solution for:

- Conveyor side guiding

- Industrial sliding gate alignment

- Automated material handling

- AGV path control systems

Designed to integrate easily, perform consistently, and reduce downtime, our gate guide rollers help ensure your equipment runs smoother, longer, and more reliably.

Why Choose Our Sliding Gate Guide Rollers?

When it comes to the smooth and reliable operation of industrial sliding systems, sliding gate guide rollers play a crucial role. Designed for durability, precision, and long-term use, our rollers ensure that heavy gates and equipment glide smoothly along their tracks — with minimal noise, minimal maintenance, and maximum stability.

Whether you’re building automated conveyor gates, warehouse sliding doors, or custom industrial machinery, our gate guide rollers are engineered to meet demanding performance standards.

Gate Guide Roller Key Features

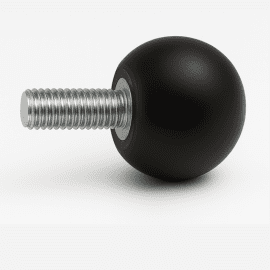

Heavy-Duty Nylon Roller Body

Made from high-strength, wear-resistant nylon (PA), these rollers offer excellent impact resistance, low friction, and quiet operation. Unlike metal rollers, they protect track surfaces from scratches and wear, extending the life of your system.

Precision 6000-Series Bearings

Each guide roller comes with a built-in 6000-series precision ball bearing, ensuring long-lasting smooth rotation even under heavy loads or continuous motion.

M10/M12 Mounting Thread – Secure & Standard

Standard M10/M12 mounting screw design ensures easy installation onto most industrial frames. The secure fastening allows for stable load support and resists vibration or loosening over time.

Gate Guide Roller Technical Specifications

| Specification | Description |

|---|---|

| Product Name | Sliding Gate Guide Roller / Gate Roller Guide / Nylon Gate Roller |

| Material | High-strength nylon (Polyamide) roller with 6000-series ball bearing |

| Mounting | M10/M12 threaded rod |

| Function | Gate alignment, track guiding, load-bearing support |

| Available Sizes (Dia x Height) | 32×40mm, 40×45mm, 40×60mm, 40×70mm, 48×50mm, 50×60mm, 50×70mm, 50×100mm, 50×120mm, 60×80mm |

Applications

Our gate guide rollers are designed for wide-ranging industrial uses:

- Sliding conveyor gates – Keep conveyor lines precisely aligned with lateral guide support

- Electric sliding doors & heavy-duty gates – Maintain smooth and quiet motion under heavy loads

- AGVs & warehouse robotics – Provide directional control and linear positioning

- Track-based mechanical assemblies – Offer load-bearing and guiding for moving structures

Designed for OEM Equipment Manufacturers

We know that as an equipment manufacturer, you need reliable, easy-to-integrate components that won’t slow down your design or production process. Our sliding gate guide rollers are made with OEM needs in mind:

- Easy to Integrate

Standard M10/M12 mounting and multiple size options let you drop them into new or existing designs — no need for custom fabrication. - Consistent Quality

We follow strict quality controls to make sure every batch performs the same — saving you time, avoiding rework, and keeping your products consistent. - Ready for Scale

Whether you need a few dozen or thousands, we’re ready. With bulk production capacity and tech support on hand, we make sourcing simple.

A Smart Pick for End Users & Maintenance Teams

If you’re maintaining or upgrading equipment, these rollers are designed to make your job easier and your machines run better:

- Quick to Replace

Simple structure = easy swap. No special tools, no fuss. - Low Maintenance

The durable nylon body and precision bearings last longer, cutting down on how often you need to replace them. - Track-Friendly & Rust-Resistant

Nylon doesn’t scratch metal rails, and it holds up well in humid or semi-outdoor environments — no rust, no noise.

Gate Guide Sizing & Maintenance Tips

✅ How to Choose the Right Sliding Gate Guide Roller:

- Load Capacity: Heavier gates require larger-diameter rollers (e.g., 50–60mm)

- Track Width: Match the roller width to your track or guide groove

- Mounting Space: Ensure you have sufficient clearance for the selected height

🛠 Maintenance Recommendations:

- Clean debris from around rollers in dusty environments

- Lubricate bearings periodically for optimal performance

- For outdoor or wet environments, we offer stainless-steel versions on request

Related Product

Contact us today to:

- 📦 Request bulk pricing

- 🔍 Get a sample for testing

- 🛠 Receive technical support for sizing and selection

Let our sliding gate guide rollers become the hidden powerhouse behind your equipment’s smooth and stable movement.

The load capacity of our nylon gate rollers depends on the size you choose. Generally, the larger the diameter and width of the roller, the more weight it can handle. For example, a 60mm roller can carry significantly more than a 32mm one. To make sure you choose the best option for your setup, just reach out to our technical team with your application details — we’re happy to help recommend the most suitable gate roller guide for your needs.

Yes — the nylon material used in our standard sliding gate guide rollers is naturally corrosion-resistant, making it suitable for moderately humid conditions. However, the carbon steel bearings and bolts may rust if exposed to rain or continuous moisture. For outdoor or harsh environments, we offer custom versions with stainless steel bearings and mounting hardware. Feel free to contact us for these upgrades.

Great question! Here are three key factors to consider when selecting your gate guide rollers:

- Installation space – Make sure the roller fits the available mounting area.

- Load capacity – Heavier loads require larger rollers (bigger diameter and width).

- Track compatibility – The roller width should match your track or groove for stable guiding.

You can refer to our technical size chart or ask our engineers for help choosing the best slide gate guide roller for your application.

Absolutely. For bulk orders, we provide OEM/ODM customization. Beyond our standard nylon gate rollers, we can manufacture rollers in custom sizes, shapes, or materials such as polyurethane (PU) or stainless steel, depending on your application. Just send us your requirements or a drawing — we’re happy to discuss your custom project.

Nylon rollers offer several clear benefits over metal:

- 🧏 Quieter operation – Nylon absorbs vibration and runs quietly.

- 🛡 Track protection – Softer than metal, so it won’t scratch or damage your track.

- 💧 Corrosion resistance – Nylon holds up well to many chemicals and moisture.

- ⚙️ Lighter weight – Lighter than steel, which helps reduce overall equipment weight.

In short, nylon gate rollers are a smart, long-lasting choice for both indoor and semi-outdoor systems.

It’s super easy. Just insert the M10 /M12 threaded rod through your equipment’s mounting hole and tighten the nut from the other side. To replace a worn roller, unscrew the nut, take off the old roller, and install the new one in the same spot. No special tools required — quick and simple!