What Is Bowl Conveyor?

The bowl conveyor is mainly used for conveying sticky products with juicy and oily, and its design is flexible, combining horizontal conveying and vertical conveying. Products are discharged into the hopper which’s with chain.Delivery to the specified point.The advantages of this conveying method are: fully sealed, no leakage, low material damage rate, easy to clear and reduced defective products during conveying. At the same time It can be used for secondary conveying due to the height limit of the plant.reducing the total height of the packaging system. Make automatic packaging machines are used in low ceiling plant.

Why Choose a Bowl Elevator for Sticky Material Handling?

When you deal with products like fermented kimchi or marinated meats, you need a system that prevents product waste. Moreover, our bowl conveyor offers several strategic advantages over vibration or standard belt feeders:

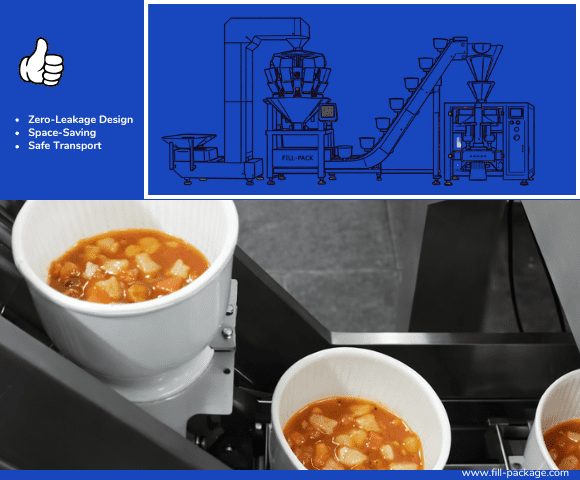

Zero-Leakage Design: Each food-grade bowl acts as an independent, sealed container. This ensures that all sauces and juices stay with your product instead of dripping onto the machine.

Space-Saving Z-Configuration: This elevator allows you to transport materials vertically and horizontally within a small footprint. Additionally, it is the perfect solution for factories with low ceilings that still require secondary feeding to a bagger.

Gentle and Safe Transport: Because the material sits statically inside the bowl, there is zero friction or agitation. As a result, the visual quality and texture of delicate items like deli meats or seafood are perfectly preserved.

Specifications

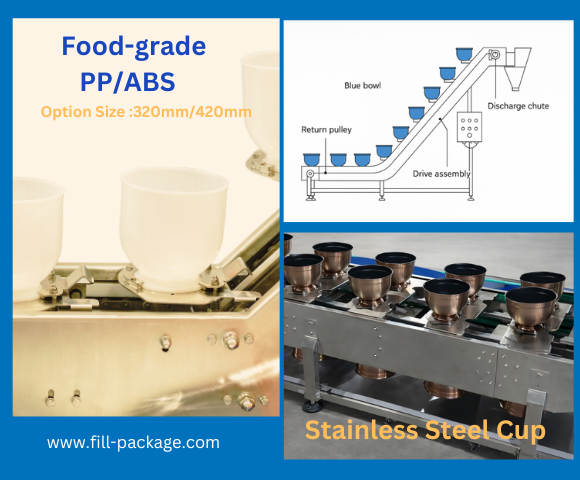

| Feature | Specification |

|---|---|

| Frame Material | Stainless Steel (Food Grade SS304) |

| Bowl Material | ABS/PP (food-grade, non-stick, optional anti-leak) |

| Bowl Pitch | Customizable |

| Speed Control | Adjustable via frequency converter |

| Motor Type | Electric geared motor |

| Capacity | Up to 3 tons/hour (depending on bowl and product type) |

| Output Height | 1.5m – 3.5m (customizable) |

| Cleaning Design | Easy-to-remove bowls, smooth surfaces |

| Certifications | CE, ISO, Food Safety Compliance Available |

Versatile Applications in Food Processing

Our bowl conveyors are widely utilized in various sectors of the food industry. Specifically, they excel in handling:

Pickled & Fermented Foods: Kimchi, seaweed salad, and pickled radishes.

Marinated Proteins: Saucy chicken wings, diced pork, and seafood mixes.

Ready Meals: Pre-cooked pasta, fried rice, and mixed vegetable dishes.

Conclusion The Bowl Conveyor is an indispensable component of an automated, high-efficiency packaging line. By combining this system with our Screw Feeder Multihead Weigher, you achieve the most reliable solution for sticky product packaging.

Why Use It as a Secondary Conveyor?

In many modern factories, the height from the weigher’s discharge point to the bagging machine’s feed point may not allow a direct drop. Here’s where the bowl conveyor shines:

1. Bypasses Structural Limitations

- Many facilities have low ceilings or obstructions that prevent a direct drop from the weighing equipment into the packaging unit.

- The Inclined Bowl Conveyor acts as a space-efficient elevator, gently moving the product down and around those limitations.

2. Ensures Consistent Feeding Across Equipment

Even if the upstream (weighing) and downstream (packaging) machines operate at different speeds or are temporarily out of sync, the bowl conveyor buffers product flow, ensuring a smooth and balanced transition.

3. Improves Line Flexibility and Modularity

This secondary conveyor allows manufacturers to reconfigure lines more easily, accommodating different packaging types or formats using the same layout.

4. Maintains Product Integrity During Multi-Stage Transfers

Especially useful for sticky, delicate, or saucy items, which could lose quality or shape if dropped abruptly from one machine to another.

🔧 Feeding & Discharge Flexibility

This conveyor system integrates seamlessly into various packaging environments:

Feeding Options

Manual: Operators can place items directly into the bowls.

Automated: Works with combination weighers or dosing systems.

Discharge Options

Pouch Packaging Machines: Ideal for stand-up bags or premade pouches.

Vertical Form-Fill-Seal Machines: For high-speed automated bagging.

Tray or Bucket Fillers: Based on custom requirements.

Simplified Sanitation for Food-Grade Standards

Maintaining hygiene in a wet or oily production environment is essential. For this reason, we have engineered the system for quick and thorough cleaning.

Tool-Free Removal: Operators can easily remove individual bowls for deep cleaning or replacement without using specialized tools. Therefore, you can switch between different recipes with minimal downtime.

Corrosion-Resistant Build: The frame is constructed from high-quality stainless steel to withstand daily high-pressure washdowns.

This conveyor excels with sticky, wet, and semi-liquid foods like marinated meats, kimchi, and sauce-covered meals.

The inclined bowl conveyor can work with a variety of downstream packaging systems depending on your product and layout:

Pre-made pouch packaging machines (pouch baggers)

Vertical Form-Fill-Seal (VFFS) machines

Tray filling or dosing equipment

This versatility allows it to fit into a wide range of packaging workflows.

No. It’s designed for food processing—made from stainless steel and removable food-grade bowls for fast sanitation.

While the speed is moderate, the system maintains a continuous flow, improving efficiency even in manual lines.

Absolutely. Everything from bowl size to motor control and discharge height can be tailored to your production setup.