Plastic Modular Conveyor Belt

Clean. Strong. Smart. That’s Modular.

The Backbone of Your Production Line: More Than Just a Belt

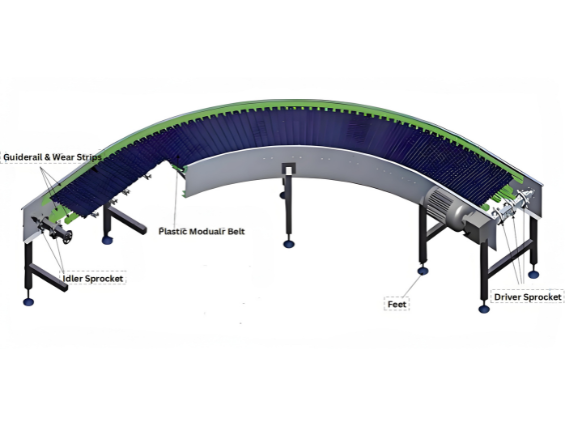

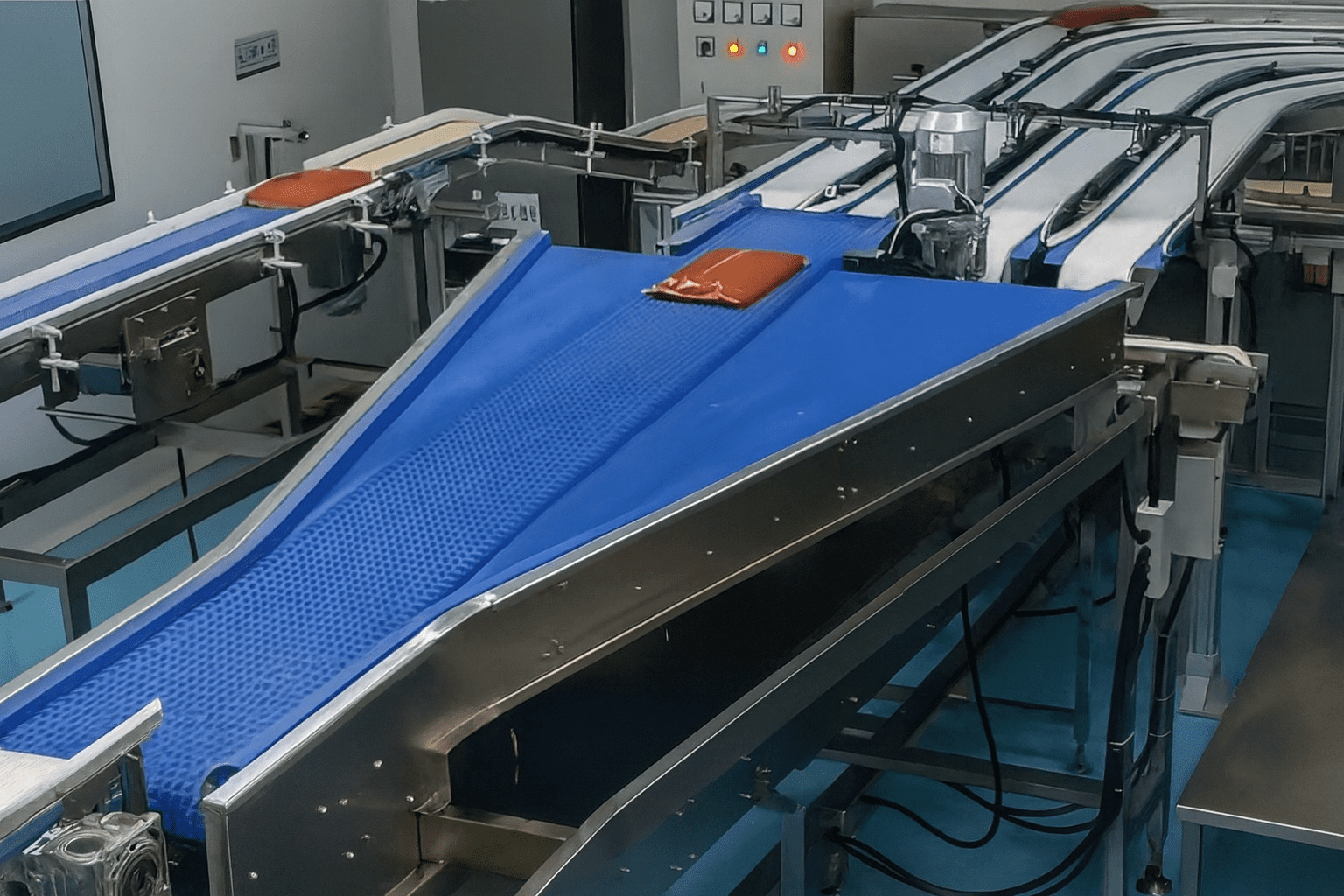

Modular conveyor belts are the core components of modern automated packaging lines. They are more than just simple “conveyor belts”; they are critical to ensuring a smooth, hygienic, and efficient flow of products from weighing and organizing to the final packaging. Unlike traditional flat belts, modular conveyor belts are composed of a series of interlocked plastic modules, much like LEGO bricks, providing unparalleled flexibility, durability, and ease of maintenance.

Is Your Conveyor System Facing These Challenges?

Problem 1: Belt Mistracking and Serpentine Movement

- We use high-precision molds for one-piece injection molding, ensuring that the dimensions and pinhole positions of each module are highly consistent.

- Precise pitch control fundamentally eliminates the tolerance accumulation that causes serpentine movement, ensuring the belt runs straight along its entire length.

Problem 2: Difficult to Clean, Promoting Bacterial Growth

- Our belts feature an open-hinge design that allows high-pressure water jets to pass through directly, easily washing away debris.

- The surface is specially treated to be smooth and non-porous, complying with FDA food-grade standards, inhibiting bacterial adhesion and making cleaning tasks much easier.

Problem 3: Belt Breakage or Module Damage

- We insist on using 100% virgin engineering plastics (such as POM, PP), never adding any recycled materials, to ensure superior mechanical strength and durability.

- We offer a variety of material options for different application scenarios to cope with harsh environments such as high temperatures, low temperatures, oil, or chemicals.

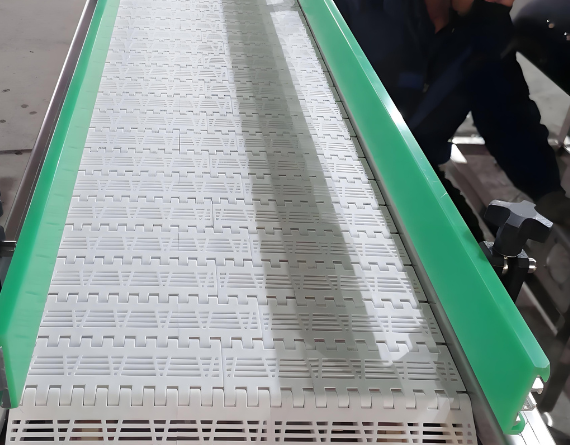

Problem 4: Complex Replacement, High Maintenance Costs

- A unique pin-locking system allows for easy removal and installation of individual modules with just a screwdriver, no special tools required.

- If a part of the belt is damaged, you only need to replace the damaged modules, not the entire belt, significantly reducing maintenance costs and repair time.

What Is a Modular Conveyor Belt?

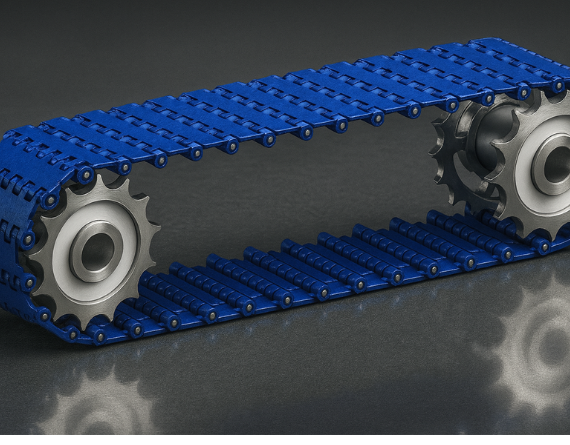

A modular plastic conveyor belt, also known as a plastic chain conveyor belt, is constructed from a series of thermoplastic modules linked together with solid plastic rods. Unlike traditional belts, modular belts utilize a “bricklayed” pattern, enabling custom widths and enhanced lateral strength. These belts are positively driven by sprockets, eliminating slipping and increasing reliability—ideal for high-load, high-precision tasks

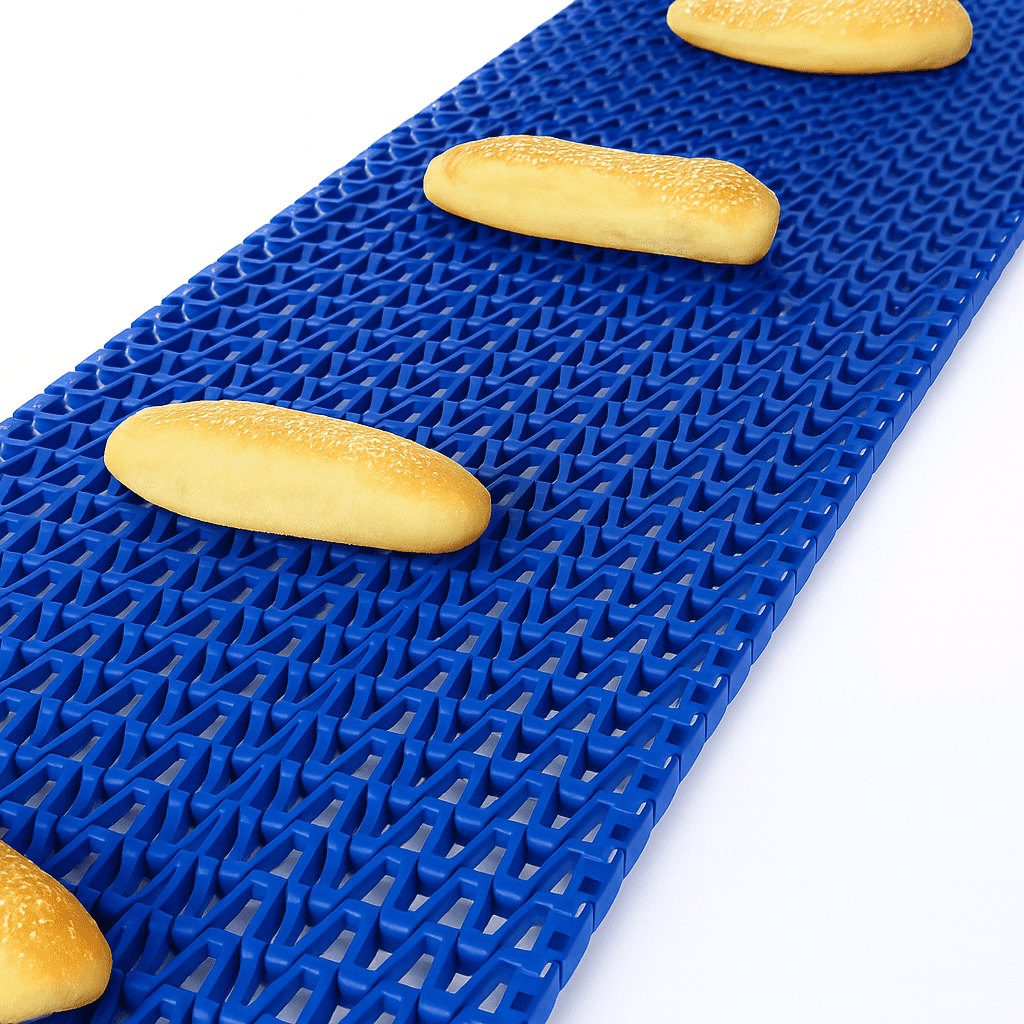

Types of Modular Conveyor Belts

Surface Type | Description | Best Use Case |

Flat Top | Smooth, solid surface | General purpose, conveying packaged goods, cartons, or trays. Easy to clean. |

Flush Grid | Open grid surface | Applications requiring drainage, airflow, or passage of small debris (e.g., washing vegetables, cooling baked goods). |

Raised Rib | Elevated ribs running along the belt | Lifts products to allow for bottom-side processing or to run on specific tracks. |

Friction Top | High-friction inserts on the surface | Incline or decline conveyors, preventing product slippage. |

Roller Top | Embedded rollers on the surface | Low-pressure accumulation zones, allowing products to queue without damaging the belt or drive. |

Perforated Flat Top | Flat surface with small holes | Combines a smooth surface with drainage capabilities, ideal for dewatering delicate products. |

The Science of Pitch & Sprocket Matching

- Pitch: The distance between the centers of two adjacent module pins. Common pitches include 12.5mm, 17.5mm, 25.4mm, and 54.8mm.

- Small Pitch: Ideal for tight transfers and conveying small products.

- Large Pitch: Suitable for heavy-duty applications and longer conveyor runs.

- Sprocket Matching: The sprocket teeth must perfectly engage with the belt’s underside. We offer both engineering plastic and stainless steel sprockets to match your chosen belt and application environment.

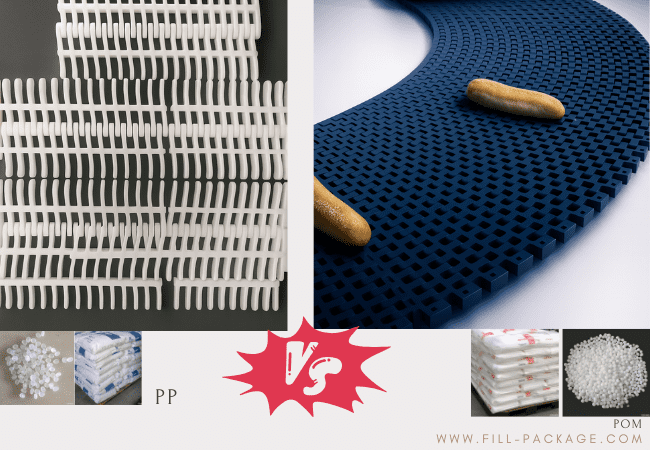

Material Showdown: POM vs. PP

POM (Polyoxymethylene): The All-Rounder

- Core Advantages: High mechanical strength, excellent wear resistance, low coefficient of friction.

- Applicable Scenarios: General food conveying at ambient temperatures, applications requiring a flat, scratch-resistant surface.

- Recommendation: For most standard packaging conveyor applications, POM is the most cost-effective and reliable choice.

PP (Polypropylene): The Chemical-Resistant and Economical Option

- Core Advantages: Excellent chemical resistance, good fatigue resistance, cost-effective.

- Applicable Scenarios: Primary processing of products requiring frequent washing (vegetables, fruits, seafood), environments with acidic or alkaline substances.

- Recommendation: When chemical resistance and cost are the primary considerations, PP is the ideal choice.

Industry Applications

Modular conveyor belts are widely used across many industries due to their versatility and cleanability:

| Industry | Application Examples |

|---|---|

| Food Processing & Beverage | Meat, seafood, baked goods, fruit, vegetable washing & packing lines. |

| Pharmaceuticals | Transport of tablets, capsules, and liquid bottles in sterile environments. |

| Automotive & Battery Lines | Heavy component conveying, electric battery module assembly. |

| Packaging & Container Handling | Bottles, cans, and boxes—stable transport and gentle accumulation. |

| E-Commerce & Warehousing | High-speed sortation and parcel routing in logistics hubs. |

| Special Processes | Cooling, drying, washing—Flush Grid and Perforated Top designs are ideal. |

Maintenance Tips

- Routine Inspection: Regularly check for cracks, wear, or broken modules. Damaged parts can be replaced individually without tools.

- Cleaning: Use food-safe cleaners to maintain hygiene. Open-grid designs are especially easy to rinse and sanitize.

- Drive Alignment: Ensure sprockets and shafts are aligned for smooth tracking and to avoid skipping or wear.

- Frame & Accessories: Check guides, side rails, and motors to prevent vibration or material jamming.

How to Select the Right Belt: A Step-by-Step Guide

- Identify the Application: What are you conveying? What are the environmental conditions?

- Choose the Surface Type: Flat Top, Flush Grid, etc.

- Determine the Pitch: Measure the distance between module pins.

- Select the Material: POM or PP.

- Specify the Width and Length.

Key Benefits of Modular Plastic Conveyor Belts

Replacement Indicators:

- Visible cracks or damage to modules.

- Elongation of the belt, leading to poor sprocket engagement.

- Severe wear on the underside of the belt or sprocket teeth.

- FDA & USDA Compliant: All our food-grade belts are made from materials that comply with FDA and USDA regulations.

- ISO 9001 Certified: Our manufacturing processes adhere to strict quality management standards.

- 100% Virgin Plastic: We guarantee that all our belts are made from 100% virgin engineering plastics, ensuring maximum strength and durability.

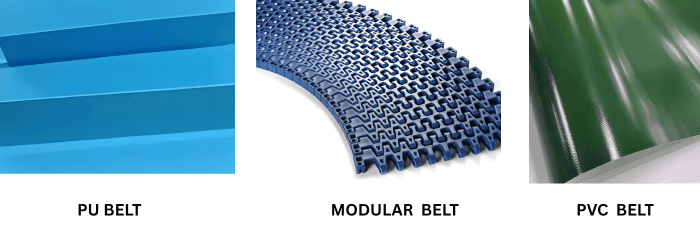

- Modular Conveyor Belt vs. PVC & PU Belts

Feature | Modular Belt | PVC Belt | PU Belt |

Structure | Interlocked plastic modules | Single-piece fabric with PVC coating | Single-piece fabric with PU coating |

Durability | ⭐⭐⭐⭐⭐ (Excellent) | ⭐⭐⭐ (Good) | ⭐⭐⭐⭐ (Very Good) |

Repairability | ⭐⭐⭐⭐⭐ (Replace single module) | ⭐ (Replace entire belt) | ⭐ (Replace entire belt) |

Hygiene | ⭐⭐⭐⭐⭐ (Easy to clean) | ⭐⭐ (Difficult to clean) | ⭐⭐⭐ (Moderate) |

Customization | ⭐⭐⭐⭐⭐ (Any width/length) | ⭐⭐⭐ (Limited) | ⭐⭐⭐ (Limited) |

Drive Method | Positive (Sprocket) | Friction (Drum) | Friction (Drum) |

Cost | Medium | Low | High |

Long-Term Value | Excellent | Fair | Good |

Related Product

The modular conveyor belt represents a leap forward in conveying technology. With superior strength, easy cleaning, minimal maintenance, and flexible configurations, it has become the preferred choice for modern manufacturing and packaging operations.

Whether you’re handling food, pharmaceuticals, automotive parts, or e-commerce parcels, a plastic modular conveyor belt system ensures performance, hygiene, and scalability. Investing in modular belt conveyor systems means preparing your production for the future—efficient, adaptable, and sustainable.

Load capacity depends on belt type, width, and sprocket size, but modular belts can easily handle medium to heavy-duty applications—often 2-3 times stronger than traditional belts.

Yes. We offer FDA/USDA-compliant plastic materials with open grid designs and easy-to-clean structures, ideal for meat, seafood, baked goods, and produce processing.

Absolutely. That’s one of the biggest advantages—each module is replaceable, minimizing downtime and maintenance cost.

Not at all. Modular systems are designed for flexibility. You can change belt width, length, add transfers or guides easily with basic tools.

With friction top or cleated modules, these belts offer a strong grip on inclines up to 20°, making them perfect for vertical transport applications.

No lubrication is needed. They run dry and clean, which helps avoid contamination and reduces maintenance time.