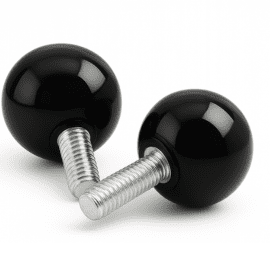

Professional Machine Handles:A Small Part That Makes a Big Difference

Choosing Your Material: A Simple Guide

Feature Comparison | Zinc Alloy Handle | Plastic Handle (Nylon) | Stainless Steel Handle |

Strength & Load | Good, ideal for most medium-duty doors. | Medium, great for lightweight doors or panels. | Excellent, the top choice for heavy-duty equipment. |

Corrosion Resistance | Good (with surface coating) | Excellent, resists moisture and most chemicals. | Superior, perfect for food & medical industries. |

Weight | Lightweight | Extremely Lightweight | Heavier |

Cost-Effectiveness | High, great value for the price. | Very High, the most budget-friendly option. | Higher initial cost, but offers the longest lifespan. |

Look & Finish | Modern industrial feel, often in black or silver. | Versatile, available in multiple colors. | Professional and clean, easy to sanitize. |

Common Uses | General packaging machines, cabinet doors. | Inspection hatches, electronic enclosures, damp areas. | Food processing lines, pharmaceutical equipment. |

Application & Advantage Of Machines Handles

The Alloy Handle: Your Go-To for Performance and Value

The Plastic Handle: Lightweight, Durable, and Corrosion-Proof

The Stainless Steel Handle: For the Toughest Jobs

Different Size Of Machines Handles

- 90mm (3.54 in): Perfect for small inspection doors or compact equipment.

- 120mm (4.72 in): A versatile, medium size used widely on electrical cabinets and machine guards.

- 180mm (7.08 in): Designed for larger, heavier doors, offering a sturdier grip and better support.

We also offer other sizes like 64mm, 96mm, 128mm, 150mm and 160mm. Just ask our sales team!

How to Choose Right Handle ?

Installation So Easy, You Can Do It in a Minute

Whether you’re installing a plastic handle, nylon handle, or even a heavy-duty alloy handle, our industrial-grade door handles are engineered for fast, secure, and tool-included installation—done in under 60 seconds.

What’s in the Box?

- 1 × Professional-Grade Door Handle

- 2 × High-Strength Hex Screws

- 2 × Slide-in T-Nuts

- 1 × Allen Wrench (Hex Key)

4 Simple Steps:

- Prep the T-Nuts: Slide them into your extrusion frame or align them for surface mounting.

- Position the Handle: Place the nylon handle or plastic handle where needed.

- Start the Screws: Insert screws through the handle into the T-nuts.

- Tighten and Secure: Use the included hex key to firmly lock everything in place.

Installation Tips:

- Ensure proper alignment and handle rotation for ergonomic use.

- Avoid over-tightening—especially for plastic and nylon handles—to maintain long-term durability.

- For aluminum extrusion frames: use the provided T-nuts for a tool-less, damage-free install.

- For metal or plastic doors: pre-drill and mount from inside the panel for a clean, flush look.

- For thin panels: use washers or backing plates to reinforce the mount.

Whether you’re upgrading a machine door handle on an industrial panel or retrofitting your enclosure with a zinc alloy handle or aluminum alloy handle, this universal system ensures a fast fit—and a strong hold.

- Care and Maintenance

Our handles are built to last, but a little care goes a long way. Simply wipe the surface with a soft cloth periodically and check that the mounting screws are tight. And because they are so affordable and easy to replace, you can always swap them out after years of use to keep your machinery looking and feeling new.

Related Product

It depends on your needs! A zinc alloy handle offers the best all-around value. A plastic handle is great for wet environments or when you need something lightweight and affordable. Stainless steel is the premium choice for hygiene-critical applications.

While we stock the most common sizes for fast delivery, we have other sizes available and also offer custom services. Contact our sales team with your requirements, and we’ll find a solution for you.

Our handles do not come with screws by default, but we can supply a complete installation kit upon request, including screws, T-nuts, and a hex key. Just let us know when you order!

For outdoor use, we highly recommend stainless steel. A coated alloy door handle can also work, but its finish may degrade over time with constant exposure. A nylon handle is best for indoor or sheltered applications, as prolonged UV exposure can cause the material to age.

We have plenty of our standard sizes in stock for quick dispatch. For large or custom orders, the lead time will depend on our production schedule. Contact us for an accurate estimate.

Absolutely! While the T-nuts are optimized for aluminum frames, the handle itself can be mounted on almost any surface. You’ll just need to pre-drill holes and use standard screws from the back. This is a common door handle for industrial machine applicatio

Ready to find the perfect handle for your equipment? Browse our collection or contact us today!