Modular Belt Conveyor

Hygienic Modular Belt Conveyor Systems

What is a Modular Belt Conveyor?

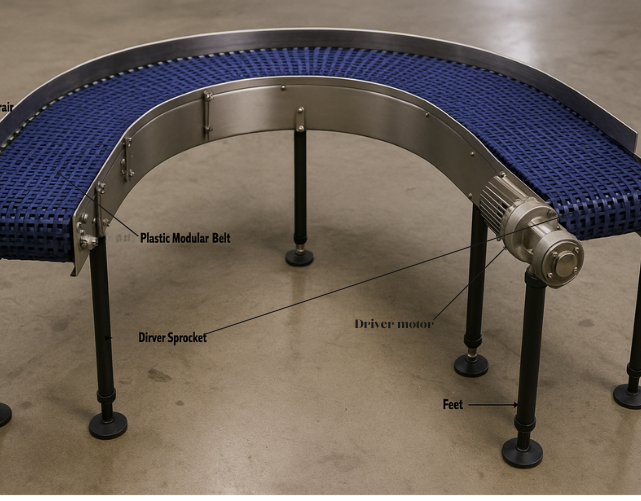

A modular belt conveyor is a highly durable transport system made of interlocked plastic modules. Unlike continuous flat belts, it features a sprocket-drive system that eliminates belt slippage. It is the industry standard for meat, poultry, and frozen food applications.

Why Choose Fill-Package Modular Belts?

- Zero Slippage: The positive sprocket drive ensures stable transport even for heavy loads or oily products.

- Smart Maintenance: Damaged belt? Simply snap in a new plastic link in minutes.

- FDA Compliance: Food-grade materials with open-grid designs for maximum airflow.

Frequently Asked Questions

Q: Can your modular belt conveyor handle high-temperature products?

A: Yes. Our modular belts are available in heat-resistant materials capable of withstanding temperatures up to 100°C (212°F).

Q: How do I clean a modular belt conveyor?

A: The open-link design allows water to flow through easily. For our Easy Clean Conveyor series, we offer a lift-able belt design for high-pressure washdowns.

What is a Modular Belt Conveyor?

Easy Maintenance: Replace individual damaged modules without changing the entire belt

Hygienic Design: Smooth surfaces and open grid options for easy cleaning

Versatile Configurations: Straight runs, curves, inclines, and declines

Long Service Life: Resistant to chemicals, moisture, and temperature variations (-40°C to +90°C)

Technical Specifications

| Feature | Details |

|---|---|

| Conveyor Belt Material | PP,PE ,POM |

| Belt Width | Customizable (Various standard options) |

| Speed Range | Adjustable; up to 30 meters per minute |

| Load Capacity | Up to 500 kg per meter |

| Operating Temperature | -40°C to +90°C |

| Drive Type | AC, DC, or Servo Motors |

| Frame Construction | Stainless Steel, Aluminum, or Powder-Coated Steel |

| Conveyor Length | Customizable to meet layout requirements |

Belt Width: 400-1200mm

Max Load: 300 kg/m

Speed: Up to 25 m/min

Applications: General packaging, light assembly, food processing

Belt Width: 600-1800mm

Max Load: 500 kg/m

Speed: Up to 30 m/min

Belt Width: 200-600mm

Max Load: 150 kg/m

Speed: Up to 20 m/min

How Modular Plastic Conveyors Work

Positive Drive Mechanism

Unlike traditional friction-driven belts, plastic modular conveyor belts are driven by sprockets that engage directly with the belt’s underside. This positive engagement guarantees consistent movement, even under heavy loads or in wet conditions.

Modular Construction

Each belt comprises individual plastic modules connected by hinge rods, creating a robust and flexible structure. This modularity allows for easy replacement of damaged sections without replacing the entire belt.

Versatility in Design

The modular nature enables customization for various configurations, including straight runs, curves, inclines, and declines.

Applications of Modular Belt Conveyors

Food Processing: Ensures hygienic handling and transportation of food products, meeting strict safety standards (FDA compliant materials available)

Automotive: Perfect for conveying heavy vehicle components like engines, transmissions, and parts

Pharmaceutical: Provides safe, controlled movement of sensitive products through production and packaging lines

Packaging: Handles various package types, including bags, cartons, and bottles, on high-speed lines

Logistics & Warehousing: Streamlines the transportation of boxes, pallets, and containers in distribution centers

Electronics Manufacturing: Gentle handling of delicate components and circuit boards

Beverage Industry: Bottle and can handling with accumulation capabilities

Modular Plastic Conveyor Belt Types & Applications

Flat Top Modular Belt

- Features: Continuous, fully closed surface

- Applications: Packaged goods, boxed items, trays, and uniform-sized products

- Benefits: Smooth ride with minimal vibration

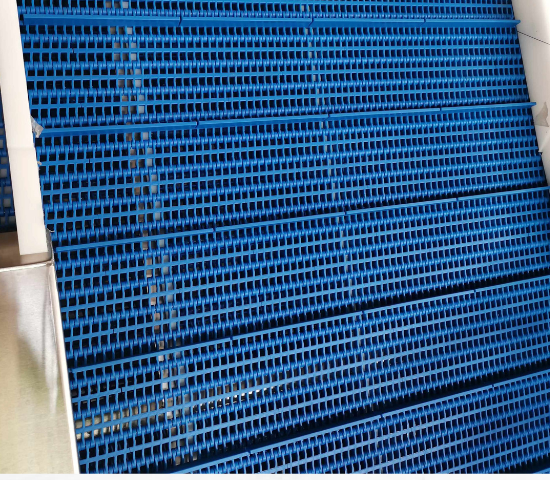

Flush Grid Modular Belt

- Features: Open grid structure for easy drainage and airflow

- Applications: Washing, cooling, draining, or drying processes (seafood, vegetables, fruits)

- Benefits: Prevents water or debris accumulation

Raised Rib Modular Belt

- Features: Raised ribs along the belt surface to maintain product alignment

- Applications: Unstable or irregularly shaped items

- Benefits: Prevents misalignment or jams during transfers

Friction Top Modular Belt

- Features: High-friction surface inserts

- Applications: Inclined conveyors (up to 20 degrees)

- Benefits: Prevents product slippage on slopes

Roller Top Modular Belt

- Features: Integrated rollers on the belt surface

- Applications: Low-pressure accumulation zones

- Benefits: Allows products to queue without damage

Perforated Flat Top Modular Belt

- Features: Flat top with strategically placed perforations

- Applications: Cooling, drying, or processing lines

- Benefits: Balances airflow and water flow with product support

Key Advantages of Modular Belt Conveyors

Low Maintenance & Easy Repair

- Damaged sections are replaced individually—no need to change the whole belt

- Self-locking modules enable quick assembly/disassembly

- Saves time, reduces spare parts costs

Versatile Applications

- Handles wet, oily, heavy, or fragile products

- Supports complex layouts with curves, inclines, sidewalls

- Suitable for both primary production & packaging lines

Durable & Hygienic

- Made from food-grade PP, PE, POM materials

- Open hinge design allows for easy washdown

- Longer lifespan than fabric belts in demanding environments

Modular Belt Conveyors Customer Success Stories

Case Study 1: Food Processing Plant Increases Efficiency by 40%

- 40% reduction in downtime due to easy module replacement

- Improved hygiene with easier cleaning

- Extended belt life from 2 years to 5+ years

Case Study 2: Manufacturer Meat and Poultry Production

- 500 kg/m load capacity handled heavy parts with ease

- Positive drive system eliminated slippage issues

- Customized width optimized for their production line layout

Why Choose Fill Package Modular Belt Conveyors?

✅ Customization Expertise: We tailor every conveyor to your exact specifications

✅ Quality Materials: FDA-compliant, food-grade plastics available

✅ Fast Delivery: Standard models ship within 2-3 weeks

✅ Technical Support: Lifetime support from our experienced engineers

✅ Competitive Pricing: Direct manufacturer pricing without middlemen

✅ Global Shipping: We ship worldwide with reliable logistics partners

Want a Conveyor That Saves Time & Money?

Choose modular belt conveyors for lower maintenance, flexible application, and long-term reliability.

Modular belt conveyors use interlocking plastic modules connected by hinge rods, offering superior durability and easy maintenance. Fabric belt conveyors use continuous fabric belts, which are quieter but require full belt replacement when damaged. Modular belts are ideal for heavy-duty, high-hygiene applications.

Our modular belts are made from high-quality thermoplastics, including Polypropylene (PP), Polyethylene (PE), and Polyoxymethylene (POM). We also offer FDA-compliant, food-grade materials for food processing applications.

Yes! Modular belt conveyors are highly versatile and can be configured for straight runs, curves (45°, 90°, 180°), inclines, and declines. Special belt designs like friction top modules are available for inclined applications.

With proper maintenance, modular conveyor belts typically last 5-7 years in standard industrial applications. In food processing environments with frequent cleaning, lifespan is typically 3-5 years. Individual modules can be replaced as needed, extending overall belt life.

Our modular belt conveyors can handle loads up to 500 kg per meter, depending on the model and configuration. For specific load requirements, please contact our technical team for a customized solution.

Absolutely! We offer FDA-compliant, food-grade modular belts made from materials that meet strict hygiene standards. Our belts are easy to clean, resistant to bacteria growth, and suitable for direct food contact.

Standard models ship within 2-3 weeks. Custom configurations typically require 4-6 weeks for design, manufacturing, and testing. Rush orders may be available upon request.

Yes, we offer installation support, training, and maintenance services. Our technical team can guide you through installation remotely or provide on-site support for complex projects. We also offer maintenance contracts for ongoing support.

Pricing varies based on belt width, length, material, and configuration. Standard models start from $1,500-$5,000, while custom heavy-duty systems can range from $7,000-$30,000+. Request a quote for accurate pricing based on your requirements.

Yes! We welcome factory visits and can provide belt module samples for testing. Please contact us to schedule a visit or request samples.