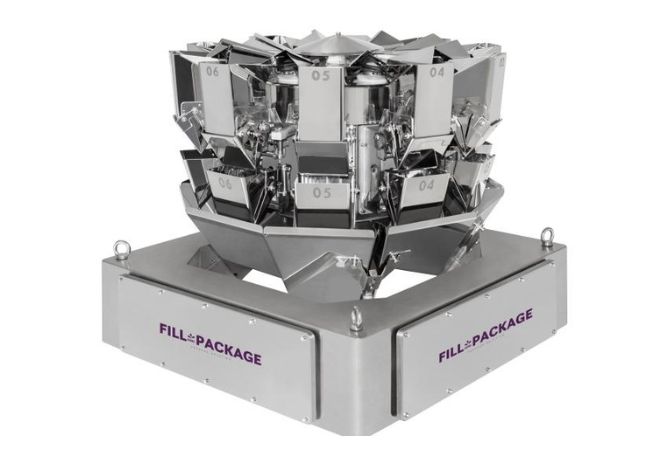

Is Our 10 Head Weighers Right for You?

If you’re looking for a cost-effective automatic weighing machine that’s easy to install, easy to use, and accurate enough to protect your margins—you’re in the right place.

The FPW-10 is one of the most popular multihead weighers used in the food industry today. Whether you’re packing snacks, nuts, frozen vegetables, or pet food, this 10-head machine delivers a strong balance between performance and price. It’s ideal for small to medium food producers who want reliable output without the complexity or high cost of larger systems.

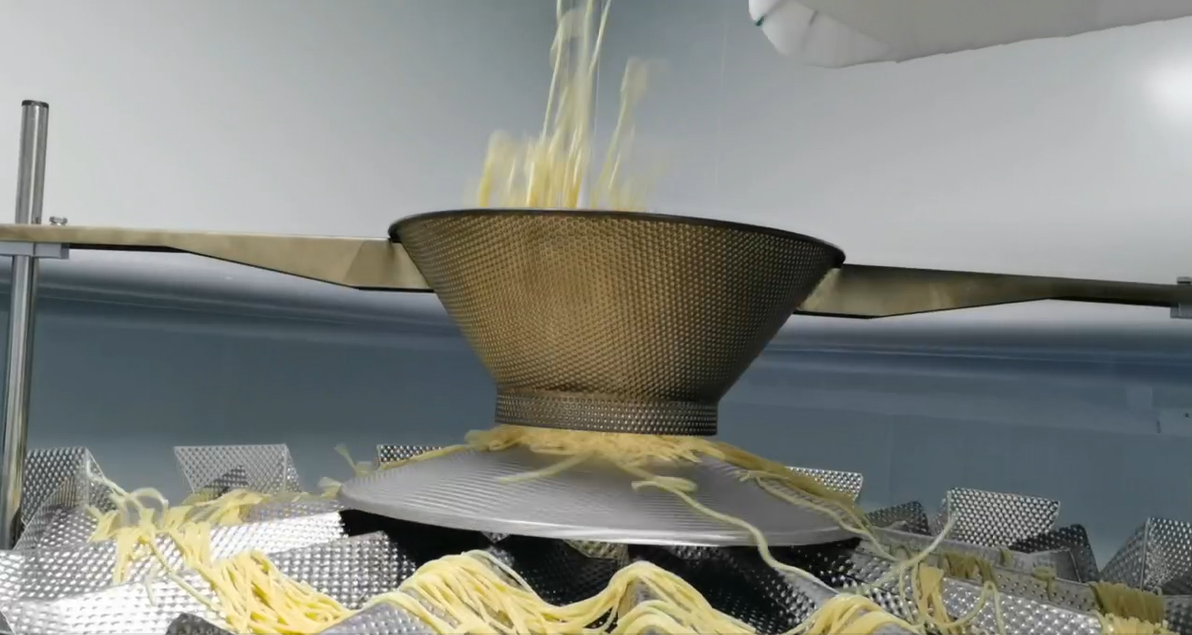

Typical Applications – Built for Food Packaging

The FPW-10 is ideal for packaging free-flowing, dry, or granular food products. Whether you’re running a small snack brand or supplying frozen foods to retail chains, this machine handles the job with speed and consistency.

Best suited for:

Roasted nuts, seeds, granola

Candy, cookies, dry snacks

Frozen vegetables, dumplings

Pet food (pellets, kibble)

Pasta, noodles, cereals

Powdered or granulated products (sugar, salt, seasoning)

Need to weigh sticky or fragile products? Check out our screw-feeding models designed for cheese, meat, gummies, or cannabis.

How We Make Sure It Works for You

Before production, we test your product (or equivalent material) in our facility. You’ll receive:

A detailed test video

Target weight combination report

Our expert feedback on accuracy and cycle speed

No guesswork. No surprises.

Only when you’re happy with the results do we start building your machine.

Key Benefits of the FPW-10

✔ Affordable investment – Our most budget-friendly multihead model

✔ Simple to operate – Learn it in under an hour

✔ Fast payback – High efficiency, low labor needs

✔ Compact size – Fits easily into small production spaces

✔ Reliable accuracy – ±0.5–3g depending on material

✔ Low maintenance – Easy to clean and quick to reset

✔ Pre-tested with your product – So you know it works before you buy

✔ Supports VFFS & pouch machines – Easy integration

Want to Know If It’s Right for You?

Don’t decide blind. Let us show you.

- Data Sheet -10 Head Multihead Weigher Packing Machine

- Specification

| Material | Stainless steel 304 |

| Bracket size | 1.6L,2.5L and 5.5L |

| Max speed | 65 bags/min |

| Waterpoof | IP63/IP65 option |

| Accuracy | 0.3g-1g (depend on material ) |

| Control display | 12 inch color screen |

| Power supply | 220V /110V 50Hz or 60Hz option |

Machine Integration:

Fill&Package multihead weighers are one most improtance part of package machine systerms ,can be connected with fill and seal machines such like : VFFS machine .rotary package machines or transfer systerms like belt conveyor and working platform etc .your products can be packaged in different bags,trays ,cups ,bottle,can,and boxes .

| Component Name | Description |

| Stepper Motor | Yanko |

| Load cell | Zemic (HBM optional ) |

| HMI controller | Kinco |

| Main Isolator | CHSO.M/Siemens |

| Circuit breaker | Schneider/Siemens |

| Leakage breaker | Schneider/Siemens |

| DC power supply | Mean well |

| Intermediate relay | Omron |

| Terminal block | Weidmueller |

❓ What You Really Want to Know — Your Top Questions Answered

Absolutely. We build our weighers with food-grade stainless steel, use stable control boards, and test each machine with a 72-hour aging run before shipment. With basic care, it can run 7–10 years easily

Yes. It’s designed for plug-and-play. We provide a setup video, parameter guide, and optional remote support. Most clients finish installation in half a day.

Before you commit, we’ll test your product (or a similar one) on a real FPW-10 in our workshop.

You’ll get:

A real test video

An accuracy report

Parameter suggestions based on your packing target

Very. No complex programming. Just enter your target weight, product type, and press start.

Most operators can learn to use it within an hour.

You won’t be stuck.

Remote support via video and chat

Universal PCB boards (shared across all our machines)

Affordable spare parts

We also recommend keeping 1–2 backup boards and key wear parts so you can solve small issues quickly without stopping production.

Typical accuracy ranges from ±0.5g to 3g, depending on your product.

We’ll show you the actual test result before you buy, so you know what to expect.