The Critical Edge for a Perfect Package

Is Your VFFS Machine Suffering From These Costly Failures?

As your component partner, we have analyzed thousands of cases of sealing and cutting failures. These are not just operational annoyances; they are symptoms of an underlying problem that can almost always be traced back to the knife and anvil set. A superior blade is your first and best line of defense.

Problem 1: Incomplete Cuts & “Chained Bags”

- Our knives are crafted from high-quality, wear-resistant tool steels, then heat-treated to an optimal hardness (typically 58-62 HRC). This ensures a razor-sharp edge that lasts for millions of cycles.

- We offer a variety of tooth profiles (e.g., standard V-shape, EZ-open) specifically designed to create a clean, tear-free cut across a wide range of film types, from thin PE to thick laminates.

Problem 2: Weak, Wrinkled, or Leaking Seals

- The primary job of a serrated VFFS knife is actually sealing. The flat tops of the serrations (the “lands”) are what press the film against the anvil to create the seal. Our blades are designed with precisely controlled land width to ensure consistent pressure and a strong, reliable seal across the entire bag width.

- The sharp “V” of the serration then performs the cut. By perfecting this geometry, we ensure a strong seal is formed just before a clean cut is made.

Problem 3: Film Sticking to Jaws & Frequent Cleaning Downtime

- All our knives are ground to a smooth surface finish to reduce sticking.

- For particularly challenging applications (e.g., sugary products, sticky films), we offer specialized non-stick coatings like Teflon (PTFE) or TiN (Titanium Nitride). These coatings create an ultra-low-friction surface that prevents buildup and dramatically reduces cleaning downtime.

The Solution: Immediately Upgrade to Our High-Performance Horizontal Serrated Cutter

Your Problem | Root Cause | Our Solution |

Weak or Bubbly Seals | Uneven blade surface, inconsistent temperature, or insufficient pressure. | Precision-Ground Surface: Ensures a perfectly flat surface for uniform pressure and heat distribution. Premium Material: Excellent thermal conductivity for rapid and stable heating. |

Incomplete Cuts, Film Stringing | Worn or dull serrations; improper blade angle. | Optimized Serration Design: This packing machine cutting blade is hardened at a specific angle for sharpness and durability, easily cutting through various composite films. |

Wrinkled Seals | Poor blade parallelism; aging silicone rubber strip. | Ultra-High Machining Precision: Guarantees perfect parallelism after installation, working with a quality silicone strip for even pressure. |

Film Sticking | Poor surface treatment; insufficient smoothness. | Special Surface Treatment: Ultra-smooth finish with high hardness and anti-stick properties, effectively reducing material residue. |

Frequent Replacements | Inferior material, insufficient hardness, prone to wear. | High-Strength Alloy Steel: Our industrial cutting blades are extremely wear-resistant, offering a much longer service life than standard parts. |

How to Replace Your Packing Blade in 10 Minutes

Step | Instructions | Key Tip |

1. Remove Old Blade | Use a hex wrench to loosen the screws securing the old cutter. | Be careful when removing the old packing blade to avoid injury. |

2. Clean the Mounting Surface | Thoroughly clean the jaw’s mounting surface with alcohol or a lint-free cloth. | A clean surface is essential for proper heat transfer and precision. |

3. Install New Blade | Align our new packaging blade with the mounting holes and place it gently. | Ensure the blade is perfectly flush with the mounting surface. |

4. Adjust Parallelism | Place a thin piece of paper between the jaws and manually close them. Adjust the screws until you feel even pressure across the entire blade. | This is the most critical step for ensuring seal quality. Be patient. |

5. Final Tightening | Tighten all screws securely in a cross-pattern sequence. | Reconnect power and air, then run a test with scrap film to check the seal and cut quality. |

The 3-Minute Guide to Choosing the Right Packaging Blades

Step | How to Do It | Our Advice |

1. Confirm Machine Model | Find the model number on your VFFS machine’s nameplate or in the manual. | Not sure?Send us a photo of your machine, and we’ll identify it for you. |

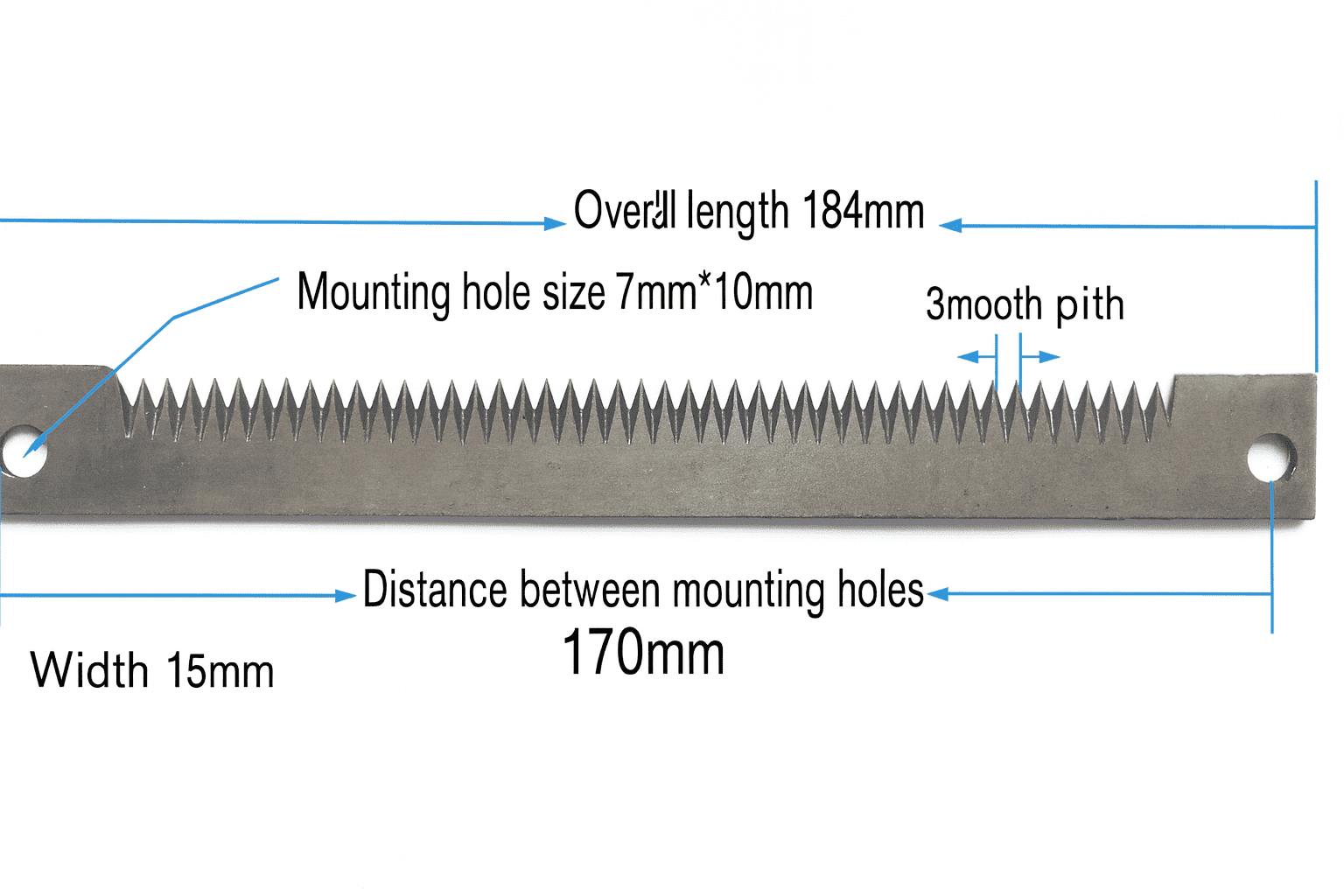

2. Measure Key Dimensions | Measure the Total Length (L), Width (W), Thickness (T), Hole Distance (P), and Hole Diameter (D). | This is the backup plan, but it’s very effective for all industrial cutting blades. |

3. Select Serration Type | Choose from flat, fine, or coarse/wave serrations based on your film. | Send us a sample of your packaging, and we’ll recommend the best tooth profile. |

4. Choose Material & Process | Select from standard alloy steel, special hardened steel, or a non-stick coating based on your product. | For abrasive materials like powders or granules, we recommend special hardened steel. |

Daily Maintenance to Double Your Cutter's Lifespan

- Daily Cleaning: After production, wipe the blade surface with a soft cloth to remove residue. Never use a metal brush!

- Regular Inspection: Check the sharpness of the serrations weekly. Plan for replacement if you notice minor wear.

- Correct Parameters: Avoid running the machine at excessively high temperatures and pressures for extended periods.

- The Perfect Match: Replace aging Teflon tape and silicone rubber strips at the same time to maximize the new cutter’s performance

- A Guide to VFFS Knife Features

- Material Science: Choosing the Right Steel for the Job

- Tooth Profile: The shape of the serrations. The most common is a “V” profile. We also offer “EZ-Open” or perforated profiles that create an easy-to-tear line for the consumer.

- Tooth Pitch: The distance between teeth. A finer pitch is often used for thinner films, while a coarser pitch is used for thicker, tougher films.

- Hole Pattern: We stock knives to fit all major VFFS machine brands, including Ishida, TNA, Rovema, Sandiacre, and more. We can also create custom hole patterns from your drawing or sample.

- The Anvil: The knife cuts against an anvil, which is typically a strip of silicone rubber or other resilient material. The condition of the anvil is just as important as the knife. A worn or hardened anvil will lead to poor cuts. We recommend replacing the anvil every time you replace the knife.

Model No. | Length (mm) | Width (mm) | Hole Distance (mm) | Mounting Hole Size (mm) | Remart |

Width :10mm | 3 x 8 | ||||

LFD-12010 | 120 | 10 | 110 | 3 x 8 | |

LFD-12510 | 125 | 10 | 115 | 3 x 8 | |

LFD-14010 | 140 | 10 | 130 | 3 x 8 | |

LFD-14510 | 145 | 10 | 135 | 3 x 8 | |

LFD-16010 | 160 | 10 | 150 | 3 x 8 | |

LFD-17510 | 175 | 10 | 165 | 3 x 8 | |

LFD-18010 | 180 | 10 | 170 | 3 x 8 | |

LFD-19510 | 195 | 10 | 185 | 3 x 8 | |

LFD-20010 | 200 | 10 | 190 | 3 x 8 | |

Width:15mm | 7 x 10 | ||||

LFD-17815 | 178 | 15 | 163 | 7 x 10 | |

LFD-18015 | 180 | 15 | 165 | 7 x 10 | |

LFD-18515 | 185 | 15 | 170 | 7 x 10 | |

LFD-21515 | 215 | 15 | 200 | 7 x 10 | |

LFD-23515 | 235 | 15 | 220 | 7 x 10 | |

LFD-25515 | 255 | 15 | 235 | 7 x 10 | |

LFD-28515 | 285 | 15 | 270 | 7 x 10 |

Material | Characteristics | Best For |

High-Carbon Steel | Good hardness and wear resistance at a cost-effective price. The industry standard. | General-purpose applications with standard packaging films. |

High-Speed Steel (HSS) | Contains tungsten and molybdenum. Significantly higher wear resistance and toughness than standard steel. | High-speed, high-volume applications. Cutting through thicker or tougher film structures. |

Powdered Metal (PM) HSS | An advanced form of HSS with a finer, more uniform grain structure. | The ultimate in performance. Offers the longest lifespan and is ideal for the most demanding applications. |

Stainless Steel | Excellent corrosion resistance. | Washdown environments or when packaging corrosive products. Softer than tool steels, so lifespan may be shorter. |

Related Product

We provide high-quality compatible parts that use materials and manufacturing processes equal to or better than OEM standards. You get OEM-level performance at a more competitive price, with full after-sales support.

Don’t worry! We provide detailed illustrated guides and online video tutorials. You can also contact our technical support anytime for one-on-one remote installation guidance.

Yes! We support custom orders from drawings or samples. Whether you need a special size, tooth profile, or material, we can meet your unique production needs.

We offer a 3-month quality guarantee. We will unconditionally provide a return or exchange for any non-human-caused quality issues under normal use.