Z-Type Bucket Elevator: The Standard for Continuous Material Feeding

Introduction

In a high-speed automated packaging line, maintaining a steady flow of product is essential for weighing accuracy. Specifically, our Z-type bucket elevator acts as the “reliable pulse” of your system. It continuously moves loose solids from the ground level to high-position weighers with zero fuss. Consequently, you eliminate bottlenecks and ensure your multihead weigher always operates at peak capacity.

Bucket Elevators

The Z-Type Bucket Elevator is a precision-engineered transport conveyor specifically designed for handling loose, small granular powders and particulate materials. Built for optimal efficiency and product protection, this bucket elevator is commonly used in industries such as food processing, snacks, agriculture, pharmaceuticals, and chemicals.

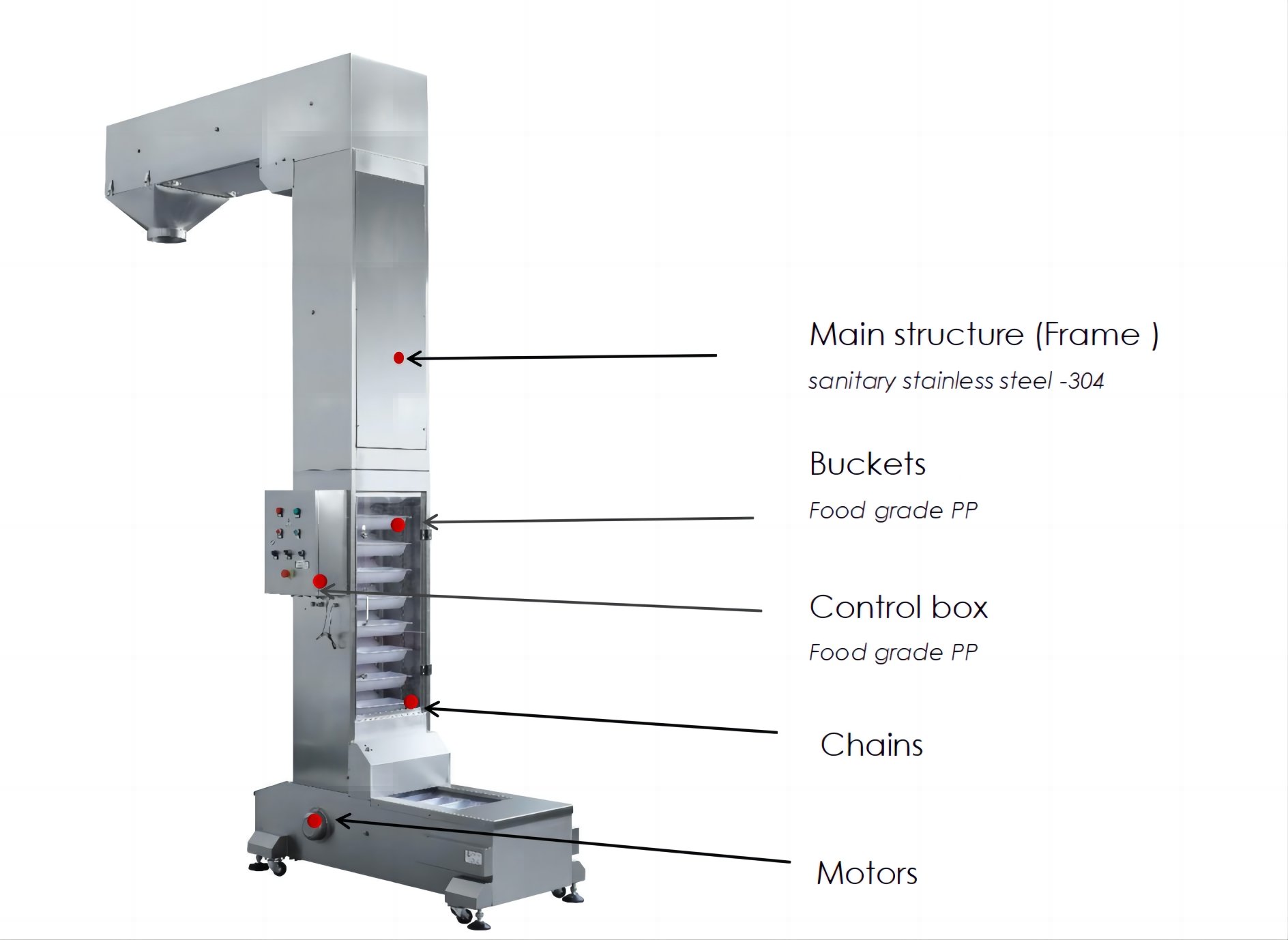

Crafted with a stainless steel frame to ensure durability and hygiene, this elevator features plastic buckets made primarily from PP (Polypropylene), with optional ABS (Acrylonitrile Butadiene Styrene) materials for different application needs. These materials are chosen for their lightweight, corrosion-resistant, and food-safe properties, making them ideal for transporting delicate or contaminant-sensitive products.

The Z-type configuration allows the buckets to move in a vertical and horizontal direction, maximizing space utilization and enabling smooth product transfer from the feeding point to the discharge outlet. Bulk material is evenly distributed into each bucket via a vibration feeder, minimizing spillage and ensuring accurate handling.

Key features of the Z bucket elevator include:

- Continuous and gentle handling of fragile materials

- Customizable bucket sizes based on the type and volume of the material

- Fully enclosed design to prevent contamination

- Chain-driven mechanism supported by pulleys or sprockets at both the head and tail ends

- Seamless integration with upstream feeding systems and downstream packaging equipment

Whether you need to move lightweight powders or small particle-sized materials, this bucket elevator offers a cost-effective

How Does Bucket Elevator Work?

When you need to move large volume of bulk materials quickly ,bucket elevators are popular choice .Similar to the conveyor belt, the bucket elevators are used to transport bulk materials vertically, the difference is that the bucket elevators uses the buckets on the chain transport materials, it is consisted of machine bed, chains, buckets, motor drive chain to drive the bucket body operation, the object from an end point to the designated location, and then discharge the material.

Each buckets elevator is came with a control box, which includes the following control buttons: work ,run ,stop, run, emergency stop,adjustable speed,automatic/manual and inching, easy and convenient to operate. The control panel has two single cables used to connected with the multihead weighers, which ‘s automatically control the feeding quantity of the Z-bucket conveyor through sign form weighers, and automatically feed and stop.

Why the Z-Type Configuration is Essential for Modern Plants

The “Z” shape is not just for aesthetics; it is a strategic engineering choice for facility managers. Moreover, this equipment offers several critical advantages for your integrated line:

Continuous Material Flow: Multiple small food-grade buckets move in a seamless loop. Therefore, your feeders receive a constant supply of product without the surges common in batch loading.

Maximum Space Efficiency: The vertical lift design minimizes the floor footprint. Specifically, it allows you to install high-output lines even in facilities with limited horizontal space.

Gentle Handling: Unlike auger conveyors, buckets carry the product without friction. As a result, you prevent breakage for fragile items like snacks, nuts, and crystalline products.

Engineered for Hygiene and Durability

We understand that downtime for cleaning is expensive. For this reason, our Z-type elevators feature a “clean-first” construction:

Food-Grade Buckets: We use reinforced polypropylene (PP) buckets that are safe for direct food contact and easy to sanitize.

Robust Stainless Steel Frame: The entire structure utilizes 304 stainless steel. Furthermore, we polish the surfaces to ensure dust and particles do not accumulate in the seams.

Modular Chain System: The high-tensile chain ensures long-term stability. Consequently, you spend less time on tension adjustments and more time on production.

Material Selection: Stainless Steel vs. White Coated Surface

We offer two distinct surface finishes to meet different industrial requirements and budget levels. Moreover, each finish serves a specific operational purpose:

1. Professional White Coated Surface (Carbon Steel)

This version features a high-durability white industrial coating over a carbon steel frame.

Easy Maintenance & Protection: The white coating is easy to clean and makes dust or stains visible immediately. Specifically, it protects the underlying structure from wear, extending the machine’s lifespan.

Visual Clarity: The bright white finish improves workshop brightness and reduces operator eye fatigue. Therefore, it is ideal for general packaging environments in the food and chemical industries where aesthetics and cleanliness are high priorities.

2. Full Stainless Steel Surface (SUS304/316L)

Designed for strict hygiene environments, this version uses food-grade stainless steel.

Maximum Hygiene & Safety: Stainless steel naturally resists rust and corrosion. Consequently, it meets the highest food and pharmaceutical standards (FDA compliant), preventing material contamination.

Extreme Durability: This material handles high-load operations and harsh washdown environments without deforming. In addition, it supports IP54-rated sealing to prevent dust and moisture ingress.

Feature Box

- Standard Discharge Height: 3200m (customized other size )

- Standard In-Feed Length: 860mm

- Variable Speed Control: As required

- Bucket Selection: 2L, 4L & 6L

- Machine type: Z type and multiple discharge outlets

- Frame Material: Stainless Steel 304

- Bucket Material :Food grage plastic (PP)

Related Product

Conclusion The foundation of a reliable packaging line starts with the right feeding strategy. If you are looking for a continuous, space-saving solution for your loose solid products, our Z-type elevator is the ideal choice.

Next Step: Request a Custom Layout Need to fit this into a tight space? Contact our engineering team for a 3D layout of your Z-type conveying system today.

The Z-Type elevator features a vertical and horizontal movement path, making it ideal for facilities with limited floor space. Its design ensures gentle handling and a fully enclosed transport system.

The buckets are made from food-grade plastic materials—primarily PP (Polypropylene) or ABS. These plastics are durable, lightweight, and resistant to corrosion and chemicals.

This bucket elevator is best suited for loose, small particulate materials such as rice, grains, nuts, dry powders, small candy pieces, seeds, and similar products.

Yes, the elevator is designed for seamless integration with vibration feeders, multihead weighers, and automatic packaging systems, streamlining the entire production line.

A vibration feeder ensures consistent and even distribution of bulk material into each bucket, optimizing the loading process and reducing waste or spillage.