Genuine Parts for Uninterrupted Performance

At Fill Package, we understand that the efficiency of your packaging line depends on every component working in perfect harmony. Our comprehensive spare parts program ensures your multihead weighers, conveyors, and packaging machines maintain peak performance throughout their operational life. With over 10 years of manufacturing expertise and a 95% customer retention rate, we provide the reliability and support your business demands.

Our Spare Parts Categories (25)

1. Multihead Weigher Parts

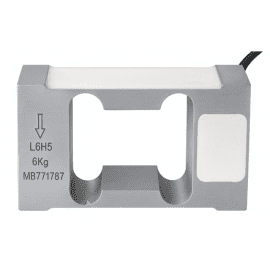

Load Cell

- What it is: A high-precision sensor that converts the force of weight into an electrical signal.

- Why it’s critical: It’s the heart of the weighing system. A faulty load cell leads to inaccurate packaging, product giveaway, and compliance issues.

- When to replace: When you see inconsistent weights, drifting values, calibration failures, or physical damage.

- Learn More About Load Cells >

Elevator Bucket

- What it is: A container used in Z-type or bucket elevators to vertically transport bulk product to the weigher.

- Why it’s critical: Ensures a gentle, continuous, and hygienic flow of product. Damaged buckets can spill product or jam the system.

- When to replace: When cracked, heavily worn (especially on the lip), or when changing products requires a different material (e.g., for food safety).

- Learn More About Elevator Buckets >

2. Conveyor System Parts

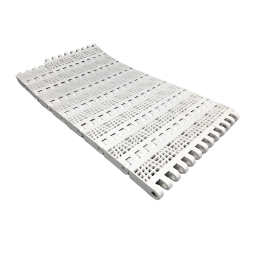

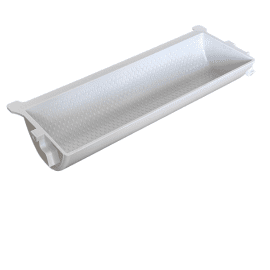

Modular Conveyor Belt

- What it is: A conveyor belt made of interconnected plastic modules, offering flexibility and durability.

- Why it’s critical: Provides a stable, hygienic surface for transporting products. Its modular nature allows for easy repair and cleaning.

- When to replace: When modules are broken, hinges are worn, the surface is heavily scratched (creating hygiene risks), or the belt tracks improperly.

- Learn More About Modular Belts >

Sprocket

- What it is: A profiled wheel with teeth that meshes with a chain or modular belt to transmit power.

- Why it’s critical: Ensures positive, non-slip engagement with the belt or chain. Worn sprockets cause jumping, noise, and premature belt/chain wear.

- When to replace: When teeth are visibly worn (hooked shape), cracked, or when replacing the belt/chain (recommended to replace as a set).

- Learn More About Sprockets >

Conveyor Roller Chain

- What it is: A series of linked rollers used for power transmission in heavier-duty conveyor systems.

- Why it’s critical: Provides robust and reliable power transmission. A stretched or worn chain can lead to jerky movements and system failure.

- When to replace: When the chain has stretched beyond its service limit (elongation), rollers are seized, or links are cracked.

- Learn More About Roller Chains >

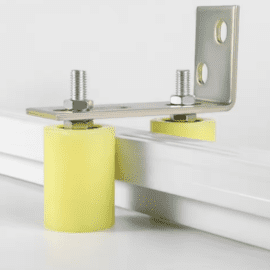

- What it is: Small wheels or bearings that guide sliding gates or guards on machinery.

- Why it’s critical: Ensures smooth and safe operation of safety guards and access panels. Worn rollers can cause jamming.

- When to replace: When they no longer spin freely, show flat spots, or have excessive play.

- Learn More About Guide Rollers >

3. Packaging Machine (VFFS) Parts

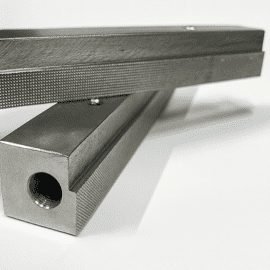

VFFS Bag Former / Trunk-Style Former

- What it is: A custom-shaped metal assembly that forms the flat packaging film into a tube.

- Why it’s critical: The geometry of the former dictates the final bag shape and quality. A damaged former causes film creasing and poor seals.

- When to replace: When the surface is scratched (causing film drag), dented, or when changing bag size/style.

- Learn More About VFFS Formers >

- What it is: A toothed belt that precisely pulls the packaging film through the machine.

- Why it’s critical: Synchronizes the film pull with the sealing and cutting actions, ensuring consistent bag length.

- When to replace: When teeth are worn, the belt is cracked, it slips, or every 12-18 months as preventive maintenance.

- Learn More About Timing Belts >

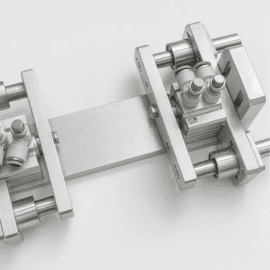

- What it is: The heated metal bars (jaws) and the pneumatic bracket (holder) that create the vertical and horizontal seals on the bag.

- Why it’s critical: Essential for creating airtight, strong seals. Worn jaws or a faulty holder lead to leaks and product spoilage.

- When to replace: When the serrations on the jaw are worn, the non-stick coating is gone, or the holder has alignment issues.

- Learn More About Sealing Jaws >

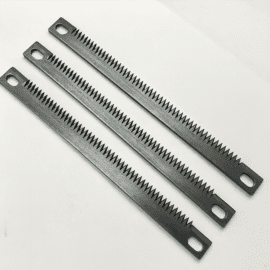

- What it is: The knife that separates individual bags after they are sealed.

- Why it’s critical: A sharp blade ensures a clean, professional-looking cut. A dull blade can tear the film or fail to separate bags.

- When to replace: When the cut quality degrades, the blade is chipped, or after a set number of cycles as part of preventive maintenance.

- Learn More About Cutting Blades >

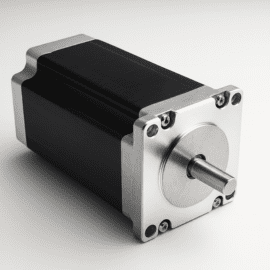

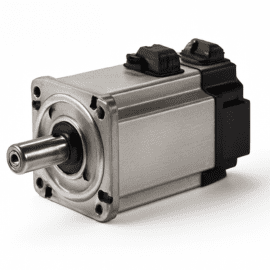

4. Universal & Control Components

- What it is: Electric motors that provide precise rotational control for tasks like film pulling and auger filling.

- Why it’s critical: Their accuracy directly impacts bag length, fill volume, and overall machine timing. Failure leads to immediate production stoppage.

- When to replace: When experiencing lost steps (stepper), position errors (servo), overheating, or excessive noise/vibration.

- Learn More About Motors >

- What it is: A sensor that uses a light beam to detect registration marks on printed film, ensuring accurate cutting.

- Why it’s critical: Without it, printed bags cannot be cut in the correct position, leading to massive waste.

- When to replace: When it fails to detect marks reliably, has a weak signal, or the lens is permanently clouded/scratched.

- Learn More About Photo Sensors >

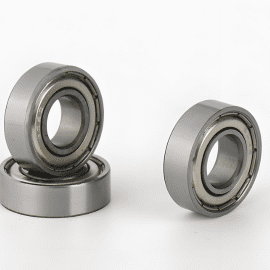

- What it is: Components that allow smooth rotation or oscillation of shafts and linkages.

- Why it’s critical: Reduce friction and support loads in all rotating parts. Failure can cause catastrophic damage to motors and shafts.

- When to replace: When you hear grinding noises, feel excessive vibration, or detect play/wobble in the shaft.

- Learn More About Bearings >

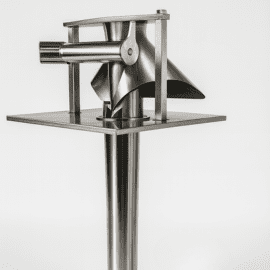

- What it is: Adjustable feet at the base of the machine for leveling and vibration damping.

- Why it’s critical: A level, stable machine runs more accurately and wears more slowly. They are crucial for precise weighing.

- When to replace: When threads are stripped, the damping pad is degraded, or they are bent from machine movement.

- Learn More About Machine Feet >

- What they are: Operator interface and access components for guards, doors, and adjustment points.

- Why they’re critical: Ensure safe and ergonomic operation and access for maintenance. Broken handles or hinges can be a safety hazard.

- When to replace: When broken, cracked, stripped, or no longer functioning correctly.

- Learn More About Operator Components >

- What it is: A versatile, low-friction, wear-resistant plastic material used for custom-machined parts like guides, bushings, or rollers.

- Why it’s critical: Often used as a sacrificial wear part to protect more expensive metal components.

- When to replace: When worn beyond its tolerance limits, cracked, or no longer providing a smooth guiding surface.

- Learn More About Nylon Rods >

Why Choose Fill Package Spare Parts?

100% authentic components manufactured to original specifications

Every spare part we supply is manufactured using the same materials, processes, and quality controls as our original equipment. This ensures perfect fit, optimal performance, and maintains your equipment warranty.

Quick Navigation to All Spare Parts

Motion & Drive Components

Forming, Sealing & Cutting

Sensing & Control

Material Handling

Structural & Operator Components

Preventive Maintenance Schedule: Avoid 90% of Unplanned Downtime

Don’t wait for a breakdown. Proactive maintenance is the most effective way to maximize uptime and extend the life of your equipment. Follow this general schedule.

Daily Checks (Before & After Production)

- Visual Inspection: Check for loose bolts, frayed wires, or visible damage on all components.

- Cleaning: Wipe down Photo Electric Sensors, clean any debris from Cutting Blades and Sealing Jaws.

- Conveyor Belt: Check for proper tracking and any visible damage.

Weekly Maintenance

- Lubrication: Lubricate Conveyor Roller Chains and check Bearing grease points.

- Tension Check: Verify the tension of Timing Belts and Conveyor Belts.

- Calibration Check: Perform a quick calibration check on Load Cells.

- Pneumatics: Drain water from air filters and check for audible leaks.

Monthly Checks

- Wear Inspection: Closely inspect Timing Belt teeth, Sprocket teeth, and Elevator Bucket lips for wear.

- Blade Inspection: Check Cutting Blade sharpness and for any nicks.

- Electrical: Check for secure connections on Stepper/Servo Motors and sensors.

Quarterly Replacement/Inspection (Every 3-6 Months)

- High-Wear Seals: Inspect and replace seals in high-cycle pneumatic cylinders.

- Filters: Replace main pneumatic air filters.

- Cutting Blades: Replace blades in high-speed, 24/7 operations.

Annual Replacement (Every 12-18 Months)

- Belts: Proactively replace Timing Belts and high-use Conveyor Belts.

- Bearings: Replace bearings in critical, high-speed rotating assemblies.

- Sensors: Consider replacing critical Photo Electric Sensors that show signs of aging.

Service Advantages

Extensive Parts Inventory

Rapid Response & Technical Support

Fllexibe Shipping Solutions

Remote Diagnostics & Troubleshooting

Preventive Maintenance Kits

Cost-Effective Solutions

Quality Assurance

Manufacturing Excellence

Traceability & Documentation

Quality Control Testing

Real-World Success Stories

Case Study 1: Solving Chronic Bag Length Issues for a Snack Food Producer

- The Client: A major snack food manufacturer in Southeast Asia.

- The Problem: Their VFFS machines were producing bags with inconsistent lengths, leading to a 12% product rejection rate and frequent downtime for photo-eye recalibration. Their existing timing belts were stretching and slipping after only 3-4 months of use.

- Our Solution: We recommended upgrading from their standard black rubber belts to our high-friction red-coated Timing Belts. We also provided guidance on proper tensioning.

- The Result: Bag length consistency improved to within ±1mm. The rejection rate dropped to less than 1%. The new belts have a service life of 14+ months, reducing annual maintenance costs by 60% and saving an estimated $25,000 per year in reduced waste and downtime.

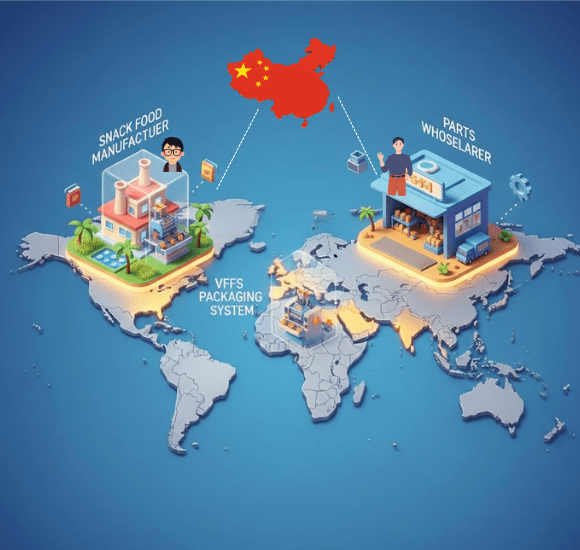

Case Study 2: Enabling a Parts Wholesaler to Win More Business

- The Client: A packaging parts distributor in the Middle East.

- The Problem: Their customers were frequently ordering the wrong parts, leading to high return rates (25%) and customer frustration. They lacked the technical expertise to guide their clients effectively.

- Our Solution: We provided them with our detailed product documentation, including our “How to Select” guides and the “Troubleshooting Quick Finder.” We also offered remote training for their sales team.

- The Result: The distributor transformed from a simple order-taker to a valued technical consultant. Their return rate plummeted to under 4%, customer satisfaction scores increased by 50%, and they secured exclusive supply contracts with two major food manufacturers.

Spare Parts Advantages - Concise Version

Continuous parts availability throughout the equipment lifecycle

We provide long-term supply commitments that ensure spare parts availability throughout your equipment’s operational life, even for older models no longer in production. Our comprehensive parts database and manufacturing capabilities enable us to support equipment for 15+ years after initial installation, protecting your investment and eliminating concerns about parts obsolescence. This includes maintaining technical drawings, reserving manufacturing capacity for legacy parts, sourcing alternatives for discontinued components, and providing proactive communication about potential supply changes.

- Unsure Which Part to Replace? Find It by Symptom

Don’t let machine downtime eat into your profits. Use this quick diagnostic table to identify the likely culprit behind common packaging line failures. Addressing the root cause saves time, money, and frustration.

Common Symptom | Potential Cause | Parts to Check / Replace | |

Inaccurate Weights, drifting values | Sensor fatigue, damage, or electrical issues | Load Cell, Control Panel, Junction Box | |

Inconsistent Bag Length, photo-eye marks missed | Film transport slipping or poor positioning | ||

Poor Vertical or Horizontal Seals, leaking bags | Worn jaws, inconsistent heat or pressure | ||

Conveyor Belt Tracking Off-Center | Uneven tension, worn belt, or roller issues | ||

Blade Not Cutting Cleanly or at all | Dull blade, misalignment, or actuator issue | ||

Vibratory Feeder Not Working or feeding unevenly | Motor failure, spring fatigue, or control issue | Vibrator Motor, Spring Set, Control Board | |

Excessive Machine Vibration or Noise | Worn rotating components or loose footing | ||

Elevator Buckets Spilling Product | Worn buckets, belt slipping, or poor alignment | ||

Pneumatic Components Sluggish or Unresponsive | Air leaks, worn seals, or valve failure | Pneumatic Cylinder, Solenoid Valve, Air Filter | |

Control Knobs or Handles Loose/Broken | Material fatigue or stripped threads |