Stainless Steel Conveyor Chain for Bucket Elevators

Power Up Your Vertical Conveying System with Reliable Performance

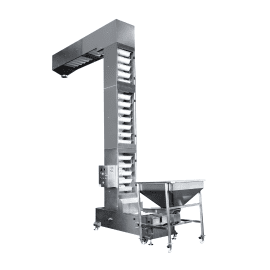

Tired of replacing worn-out elevator chains? Experiencing unstable operation or premature wear that hurts your productivity? Our conveyor roller chain is your long-term solution — specifically engineered for Z-type bucket elevator systems, vertical conveyors, and other high-load transfer setups.

With its oversized roller design, this double pitch roller chain reduces friction and noise while ensuring smooth guidance along tracks. Whether you’re conveying grains, powders, or packaged goods, it offers unmatched durability, making it ideal for both OEMs and end users who need consistent performance in tough environments.

We don’t just sell chains — we deliver long-term reliability. With 30+ years in industrial roller chain manufacturing and serving 80% of the domestic market, we’re the name you can trust.

Why Choose Our Stainless Steel Conveyor Chain?

Choosing the right conveyor chain supplier is more than just comparing prices — it’s about long-term performance, reliability, and service. Here’s why thousands of customers worldwide trust us with their stainless steel roller chains and bucket elevator chain needs:

- 30+ Years of Expertise

We’ve been manufacturing industrial roller chains for over three decades, focusing on performance, precision, and durability. - 80% Market Share in China

We are a leading bucket elevator chain manufacturer, supplying the majority of the domestic market and exporting globally. - OEM & ODM Solutions Available

Custom designs, special attachments, and private-label packaging — we support your business every step of the way. - Fast Delivery & Global Support

From urgent projects to scheduled rollouts, our flexible production and global logistics ensure you get what you need, when you need it. - Full Product Range Compatibility

We offer a complete line of conveyor roller chains, matching sprockets, attachments, and accessories — all under one roof. - Reliable After-Sales Service

Our engineering team is here 24/7 to support you with technical questions, installation advice, and long-term maintenance solutions.

Bucket Elevator Chain Specifications

| Parameter | Spec | Notes |

|---|---|---|

| Chain Model | C2052 | ANSI B29.1 C-Type Standard |

| Pitch (P) | 31.75 mm (1.25″) | Double-pitch design |

| Roller Diameter (d1) | 19.05 mm (0.75″) | Oversized roller |

| Inner Width (b1) | 9.53 mm (0.375″) | – |

| Pin Diameter (d2) | 5.08 mm (0.200″) | – |

| Tensile Strength | ≥ 21.8 KN | Approx. 6834 lbs |

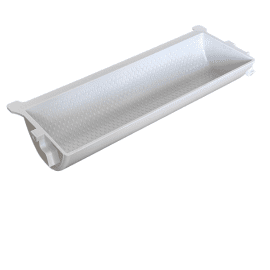

| Bucket Spacing | 127 mm | Fits 1.8L, 4L buckets |

This chain is commonly used as a bucket elevator chain or stainless steel roller chain in vertical and inclined systems.

Conveyor Chain Types/Material Configurations

| Material Combo | Roller Type | Ideal For | Features |

|---|---|---|---|

| Nickel-Plated Carbon Steel + Nylon | White Nylon | General industrial use | Cost-effective and wear-resistant |

| 304 Stainless Steel + Nylon | White Nylon | Food processing, humid areas | Corrosion-resistant, food-safe |

| 304 Stainless Steel + Steel Roller | Full Metal | Harsh chemical or high-temp environments | Maximum durability |

Whether you’re seeking a stainless steel conveyor chain for cleanroom use or a rugged industrial roller chain for heavy-duty lifting, we’ve got you covered.

Roller Chains Application

The double pitch roller chain is a popular choice for bucket elevator systems, vertical conveyors, and other industrial conveying lines where high load, smooth movement, and long service life are essential. Below is a practical guide on where it’s used and how to maintain it properly.

🏭 Food & Beverage: Ideal food-grade bucket elevator chain for grains, snacks, coffee, powders.

📦 Packaging Lines: For automated bag and material handling systems.

⚗️ Chemical & Pharma: Safely transports powders, pellets, or ingredients.

🌾 Agriculture: Lifts grains, seeds, or animal feed in silos or barns.

🛠 Other Vertical Conveyor Applications: Any system that needs a corrosion-resistant bucket elevator chain.

Maintenance Essentials – Keep Your Conveyor Chain in Top Shape

1. Maintain Correct Chain Tension

- Not too tight: Over-tightened chains cause stress on sprockets and bearings, leading to faster wear.

- Not too loose: Slack chains can jump sprockets or derail entirely — a common issue in high-load conveyor systems.

- Pro tip: Aim for 2–3% sag based on the sprocket center distance. This applies to most industrial roller chains and conveyor roller chains alike.

2. Ensure Precise Alignment During Installation

- Keep sprockets aligned and level to avoid lateral stress.

- Misalignment causes side wear and chain drift, shortening the life of your conveyor roller chain.

- For shorter center distances (<0.5m), keep the misalignment under 1mm; for longer spans, under 2mm.

3. Monitor for Wear & Replace Smartly

- Always replace the roller chain and sprockets together — mismatched wear patterns accelerate degradation.

- For stretched chains, remove even-numbered links to maintain length and pitch integrity.

- Using adjustable sprockets? Flip them when one side wears down to extend usability.

4. Regular Lubrication & Cleaning

- Lubricate between chain rollers and inner sleeves to reduce metal-on-metal friction — especially crucial for high-speed stainless steel conveyor chains.

- For long-term storage, clean with kerosene or diesel, then coat with anti-rust oil or grease.

- Periodically inspect your bucket elevator chain for dust, debris, or dried lubricant — clean and re-oil as needed.

5. Don’t Mix Old and New Chains

- Combining old and new chains leads to uneven load distribution — a top cause of premature failure in conveyor chain systems.

- Always replace sprockets with chains to maintain matched wear and optimal engagement.

Related Product

Upgrade Your Conveyor Chain — Get a Quote Now!

Stop letting worn-out chains slow down your production. Upgrade to our high-performance C2052 stainless steel roller chain and experience smoother, stronger, longer-lasting conveying.

[📩 Request a Quote] [📄 Download Datasheet] [📞 Contact Us]

Hotline: +86-13536680274

Email: [email protected]

The C2052 features oversized rollers and must be used with deep-tooth sprockets specifically designed for this chain type. Standard sprockets won’t engage properly. We also offer perfectly matched sprockets — ask us for details!

Make sure the paired chains are aligned and tensioned evenly. We recommend regular cleaning and applying appropriate lubrication based on your environment. We can also provide a full bucket elevator chain specification and maintenance guide.

Yes! In addition to standard 10-foot chain packs, we offer custom-length chains and can add special features like extended pins or custom attachments. Contact us with your specs.

Just click the button below or call our sales team directly. We’ll provide a detailed quote, technical support, and can ship samples based on your needs.

If you’re operating in demanding environments — from corrosive atmospheres to heavy-duty bucket elevators — these maintenance steps can significantly extend your system’s uptime and reduce replacement cycles.

💡 Want personalized maintenance advice for your double pitch roller chain or stainless steel elevator chain? Our engineers are happy to help — just reach out.