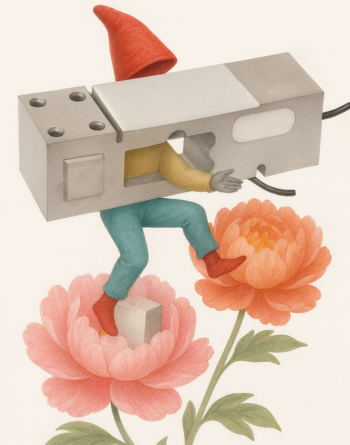

The Heart of Every Weighing System

In the world of quantitative packaging, accuracy is everything. The load cell sensor is the core component that enables precise measurement in multihead weighers, checkweighers, and filling machines. It acts as the “heart” of the equipment, a precision transducer that converts the physical force of weight into a minute, stable electrical signal, providing the foundational data for your control system.

Is Your Weighing System Showing These "Sub-Health" Signals?

Problem 1: Frequent, Unstable Weight Readings

- Every load cell we produce undergoes rigorous Eccentric Load testing to ensure consistent, accurate readings even when product is placed off-center in the weigh bucket.

- We employ a robust IP67-rated sealing process, using a proprietary potting compound that effectively blocks moisture and dust intrusion, ensuring a pure and stable signal even in the humid or dusty environments common in food processing.

Problem 2: Declining Accuracy Over Time (Zero Point Drift)

- We select high-purity aviation-grade aluminum alloy for the elastic body, which has intrinsically superior anti-fatigue properties.

- The material undergoes a strict, multi-stage heat treatment and aging process to completely release the internal stresses generated during machining. This ensures minimal creep (≤ ±0.02% F.S. / 30min) and a rock-solid zero point over long-term, high-frequency use.

Problem 3: Poor Accuracy in High-Vibration Environments

- An optimized internal strain gauge layout and proprietary damping design make the sensor mechanically insensitive to high-frequency vibrations, allowing it to respond only to the static or quasi-static force of the product’s weight.

- When paired with our digital transmitters, advanced dynamic filtering algorithms actively identify and isolate vibration signals from the machine frame, extracting the true weight data even in the most complex and noisy factory environments.

Problem 4: Permanent Damage After Accidental Overload

- Our load cells feature a mechanical stop built directly into their structure, providing up to 300% safe overload protection. This means a 5kg capacity sensor can withstand an instantaneous impact of up to 15kg without being damaged.

- This robust design feature dramatically enhances the durability and reliability of the sensor in real-world industrial environments, safeguarding your machine and your customer’s production line from costly accidents.

What is a Load Cell Sensor?

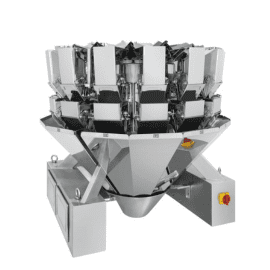

A load cell sensor is a transducer that converts applied force or weight into an electrical output. It is the core element in:

- Food packaging machines

- Retail scales and POS systems

- Logistics sorting equipment

- Medical and laboratory devices

- Hopper and silo weighing systems

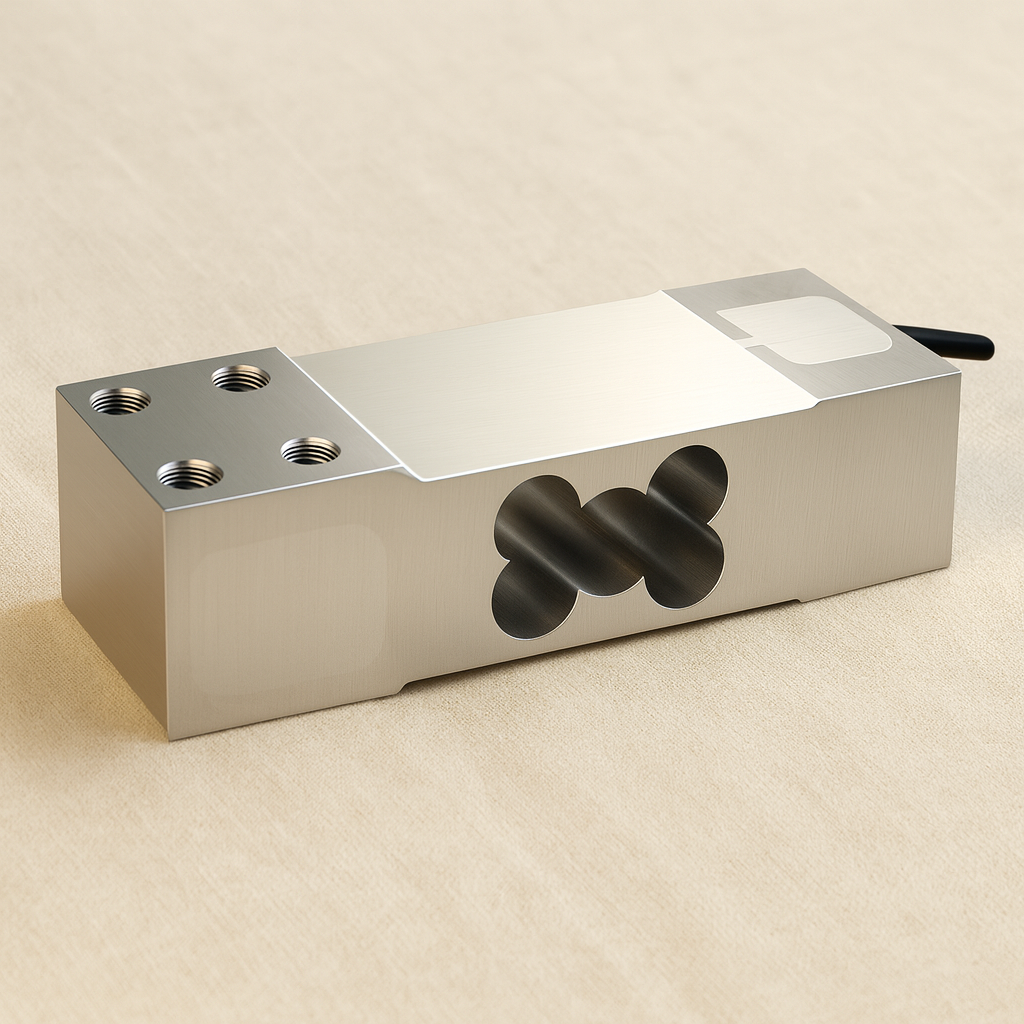

By combining compact design, robust construction, and high precision, load cells are the gold standard in weighing technology.

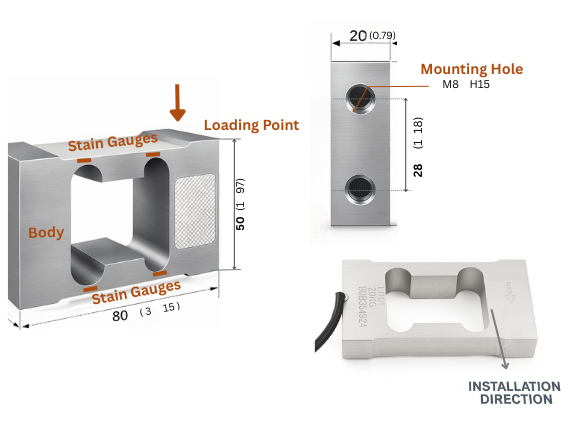

How Does a Load Cell Work? – Load Cell Working Principle

- Elastic Element (Spring Body): A precisely machined piece of high-quality metal (like aviation-grade aluminum) that deforms slightly and predictably under an applied load.

- Strain Gauges: Tiny, foil-like resistors are bonded to the surface of the elastic element. As the element deforms, the strain gauges are stretched or compressed, causing their electrical resistance to change.

- Wheatstone Bridge Circuit: The strain gauges are wired into a Wheatstone bridge circuit. This circuit is exceptionally sensitive to the minute resistance changes from the gauges and translates them into a differential voltage signal.

- Output Signal: The resulting output voltage is directly proportional to the applied force or weight. This low-level signal (typically in millivolts per volt, mV/V) is then sent to a weighing indicator or digital transmitter for amplification and processing.

How to Select the Right Load Cell for Your Machine

- Determine Single Bucket Capacity: Check your multihead weigher’s design specifications for the maximum target weight for a single bucket (e.g., 500g).

- Calculate Sensor Range: Choose a rated capacity that is significantly larger than the single bucket’s maximum target weight. For multihead weighers, a larger range provides better resolution and noise immunity. A common rule of thumb is to select a 5kg load cell for applications weighing portions up to 250g-500g. Do not choose a range that is too close to the target weight.

- Confirm Physical Dimensions: Measure the mounting hole spacing and physical dimensions of your intended installation area. We offer a variety of industry-standard sizes for direct replacement and easy design-in.

- Check Cable and Connector: Confirm the required cable length and connector type. We offer customization options to simplify your wiring harness and assembly process.

Selection Example:

- Machine Design: A 14-head multihead weigher for packaging 250g portions of potato chips.

- Analysis: The target weight per bucket is approximately 250g. To achieve high accuracy and immunity to plant vibrations, a system with high resolution and stability is essential.

- Recommended Model: Choose a 5kg rated capacity load cell. This provides ample headroom to handle dynamic loading forces while its high sensitivity ensures precise detection of even the smallest weight variations, enabling faster and more accurate combination calculations.

Installation, Calibration, and Troubleshooting

Load Cell Mounting Best Practices

- Use a Stable, Rigid Surface: Mount the load cell on a surface that is flat, rigid, and free from vibration.

- Clean All Mating Surfaces: Ensure the installation area is completely free from oil, dust, or any debris that could interfere with proper seating.

- Apply Proper Torque: Use the recommended bolt sizes and torque specifications as per the datasheet to avoid stressing the sensor body.

- Ensure Level Alignment: The load must be applied vertically. Any side forces or twisting (torsion) will severely impact accuracy and can damage the sensor.

- Maintain Clearance: Ensure no mechanical obstructions (like wires or debris) can interfere with the sensor’s slight deflection during weighing.

Load Cell Datasheet – Key Specifications

A typical load cell datasheet includes:

| Parameter | Typical Range |

|---|---|

| Output sensitivity | 1.0 – 3.0 mV/V |

| Accuracy class | C2, C3, C4, C5 |

| Combined error | ≤ ±0.03% FS |

| Creep (30 min) | ≤ ±0.02% FS |

| Temperature effect on sensitivity | ≤ ±0.002% FS/10°C |

| Input impedance | 350–450 Ω |

| Output impedance | 350–400 Ω |

| Recommended excitation | 5–15 VDC |

| Maximum excitation | 18 VDC |

| Operating temperature | -30°C ~ +70°C |

| Overload protection | 120–300% FS |

| Protection rating | IP65 / IP67 / IP68 |

Studying these parameters ensures you select the right load cell for your application.

Load Cell Applications Across Industries

Load cells are indispensable across many industries, including:

- Food packaging machines – dosing and filling accuracy

- Retail and industrial scales – commercial transactions and industrial measurements

- Logistics and postal weighing – automated sorting and billing

- Medical and laboratory devices – patient scales, dialysis, and lab balances

- Hopper and silo weighing – bulk material handling

- Batching and mixing plants – cement, chemicals, and pharmaceuticals

They ensure efficiency, compliance, and product quality.

Load Cell Troubleshooting Quick Guide

- Visual Inspection: Check for physical damage (dents, bending), a damaged cable, or foreign objects stuck between the weigh bucket and the sensor.

- Check Wiring: Ensure all cables are securely connected. Check for moisture or corrosion inside junction boxes.

- Zero Balance Test: With an empty bucket, perform a “tare.” If the reading does not stabilize at zero, there may be electrical interference or a sensor fault.

- Resistance Test (Advanced): Disconnect the sensor and use a multimeter to measure the input (Exc+/Exc-) and output (Sig+/Sig-) resistances. They should match the datasheet values (e.g., Input ~380Ω, Output ~350Ω). An open or shorted reading indicates a damaged sensor.

- Load Cell Mounting Tips – Proper Installation for Accuracy

- Load Cell Calibration Guide – Step by Step

Correct load cell mounting is critical to ensure precise readings and long-term durability. Follow these best practices:

- Choose a stable surface – flat, rigid, and vibration-free.

- Clean installation area – free from oil, dust, or debris.

- Use proper torque and bolts – as per datasheet recommendations.

- Ensure level alignment – prevents side forces that affect accuracy.

- Avoid external stresses – twisting or bending loads damage sensors.

- Follow wiring guidelines – keep signal cables away from high-power lines.

- Maintain clearance – prevent mechanical obstructions during deflection.

Proper installation guarantees long-term load cell accuracy and reliability.

Load cell calibration aligns the sensor’s output with actual physical weights. The standard process includes:

- Zero calibration (tare): Establish baseline output with no load.

- Span calibration: Apply known standard weights near full capacity.

- Multi-point calibration: Use several weights to test linearity.

- Corner load verification: Place weights at multiple points on the platform.

- Repeatability testing: Load/unload weights multiple times for consistency.

Always use certified calibration weights in stable environmental conditions.

Related Product

Load cell sensors are the foundation of modern weighing and force measurement technology. With their precision, durability, and versatility, they are indispensable in industrial automation, packaging, medical devices, and logistics systems. By understanding load cell working principles, datasheet parameters, installation techniques, calibration methods, and maintenance, businesses can ensure accurate and efficient operations.

A load cell works by using strain gauges bonded to an elastic element. When force or weight is applied, the element deforms slightly, causing changes in electrical resistance. These changes are converted into a proportional electrical signal, representing the applied load.

Load cell accuracy can be influenced by various factors, including non-linearity, hysteresis, creep, temperature fluctuations, electromagnetic interference, and improper installation. Choosing the right accuracy class (C2–C5) and proper calibration ensures reliable results.

Load cell calibration involves zero calibration (tare), span calibration with certified test weights, and multi-point testing across the full range. This ensures the output signal matches the actual applied load. Calibration should be repeated periodically or after system modifications.

Common types include:

- Compression load cells – for vertical force measurement.

- Shear beam load cells – used in tanks, silos, and industrial platforms.

- S-beam load cells – for both tension and compression.

- Torsion load cells – measure torque.

Each type is suited to specific industrial applications.

The price of load cells varies based on accuracy class, capacity, material, sealing grade, and certification. Basic models can cost under $20, while high-precision stainless steel or hermetically sealed models may exceed several hundred dollars.

With proper installation, calibration, and maintenance, load cells can last 5–10 years or more. Regular inspections, avoiding overloads, and periodic recalibration extend service life.

Load cells are widely used in food packaging machines, logistics weighing systems, medical scales, laboratory balances, batching plants, hopper and silo weighing, and industrial automation equipment.