Hinges ---Engineered for Demanding Industrial Applications

Material Selection Guide: Matching Performance to Your Application

Material | Key Advantages | Recommended Applications |

Stainless Steel | Excellent corrosion resistance, high strength, clean and smooth surface. | Food processing equipment, medical devices, chemical plants, marine environments, outdoor enclosures. |

Zinc Alloy | Balanced performance, high strength, excellent casting properties for complex shapes, cost-effective. | Industrial ovens, test chambers, automation equipment, electrical cabinets, general machinery. Our zinc hinges are a popular choice. |

Plastic (e.g., ABS/Nylon) | Lightweight, good insulation, resistant to chemicals, highly cost-effective. We offer various types, including the plastic butt hinge. | Light-duty access doors, packaging machine guards, electronic enclosures, applications requiring electrical insulation. |

Surface Finishes: Combining Protection and Aesthetics

Surface Finish | Process Characteristics | Performance Advantages |

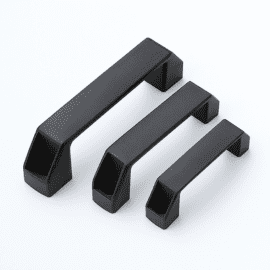

Black Oxide Finish | A dense oxide film is formed on the metal surface, resulting in a matte black look. | Good rust prevention, increased surface hardness, reduced friction, cost-effective, ideal for matching dark-colored machinery. |

Polished/Chrome Plated | Creates a mirror-like or bright, reflective surface. | Excellent corrosion and wear resistance, smooth and easy-to-clean surface, suitable for high-cleanliness environments. |

Core Features & Selection Guide

- Assess Load Requirements: Choose a hinge with the appropriate load rating based on the weight and size of your door or panel. Our heavy-duty stainless steel butt hinge models can support up to 100 kg (220 lbs) per hinge, while specific zinc hinges offer radial loads up to 1800N. Please consult the product-specific data sheet or our technical team for precise data.

- Determine the Operating Environment: Humid, acidic, or high-temperature environments demand the superior corrosion resistance of stainless steel. For standard indoor, dry conditions, zinc alloy is an ideal choice that balances performance and cost.

- Consider Installation Type: Depending on your equipment’s door structure (e.g., flush, inset, or overlay doors), choose a matching hinge type. We offer surface-mounted, concealed, lift-off, and various other mounting styles.

- Define Dimensional Specifications: We provide a wide range of standard-sized hinges. However, we also understand that one size doesn’t fit all. If you require specific dimensions, hole patterns, or opening angles, our robust customization capabilities can create a tailor-made solution for you.

Wide Range of Applications

- Packaging & Conveying Equipment: For safety guards, access doors, and control panels.

- Electrical & Telecom Cabinets: Providing sturdy door support for distribution boxes, server racks, and control cabinets.

- Industrial Ovens & Test Equipment: Performing reliably on heavy, high-temperature oven doors and environmental test chambers.

- Machinery & Automation: Suitable for custom machinery, machine tool guarding, and automated cells.

- Food & Medical Industries: Hygienic stainless steel hinges ensure safety and cleanliness.

Why Choose Us?

- Strict Quality Control: From raw material sourcing to final inspection, we enforce rigorous quality checks at every stage to ensure each product meets industrial-grade standards for durability and reliability.

- Powerful Customization: Our experienced engineering team and flexible production lines can provide fully customized solutions based on your drawings or specific requirements.

- Professional Technical Support: Our experts are ready to offer professional selection advice, installation guidance, and troubleshooting to help you find the perfect solution.

- Reliable Supply Chain: We maintain stable production capacity and efficient inventory management to ensure timely delivery for all your needs, from samples to bulk orders.

Related Product

- Stainless Steel: The first choice for humid, corrosive, or high-cleanliness environments.

- Zinc Alloy: Ideal for most indoor industrial applications, offering a great balance of strength and cost.

- Plastic: Recommended for lightweight, insulating, or cost-sensitive applications.

Each of our products has a detailed load rating specification. The capacity is related to the hinge’s design, material, installation method, and the door’s dimensions. We typically provide static load data for a single hinge as a reference. For heavy doors, we recommend using three or more hinges to distribute the load.

Yes, we offer tiered pricing for bulk orders. The larger the volume, the more competitive the price. We also have special partnership programs for long-term wholesalers and distributors.

Absolutely. We encourage testing before bulk purchasing. Please contact our sales team to apply for samples. A nominal fee or deposit may be required, which is often deductible from your subsequent bulk order.

Looking for reliable, cost-effective industrial butt hinges? Browse our wide range of plastic, zinc alloy, and stainless steel hinges — all engineered for performance, durability, and ease of installation.

📩 Contact us today for a catalog, technical specs, or a free consultation!