Heavy-Duty Machine Leveling Feet: The Foundation of Line Stability

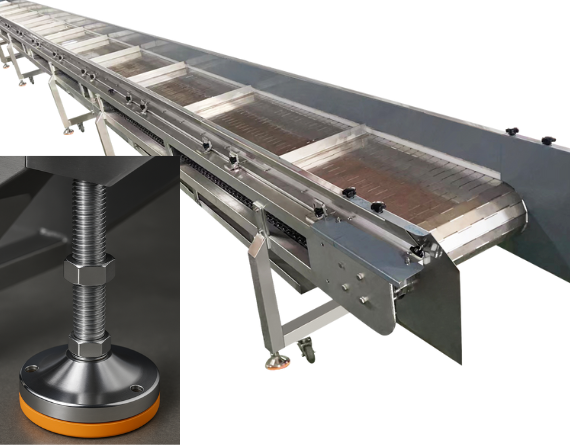

Introduction A stable foundation is essential for the long-term precision of any automated packaging line. Standard plastic feet often fail under the weight of heavy multihead weighers or vibrations from high-speed VFFS machines. Consequently, we provide high-quality stainless steel leveling feet designed to handle extreme loads while maintaining perfect equipment alignment.

What Is a Machine Foot?

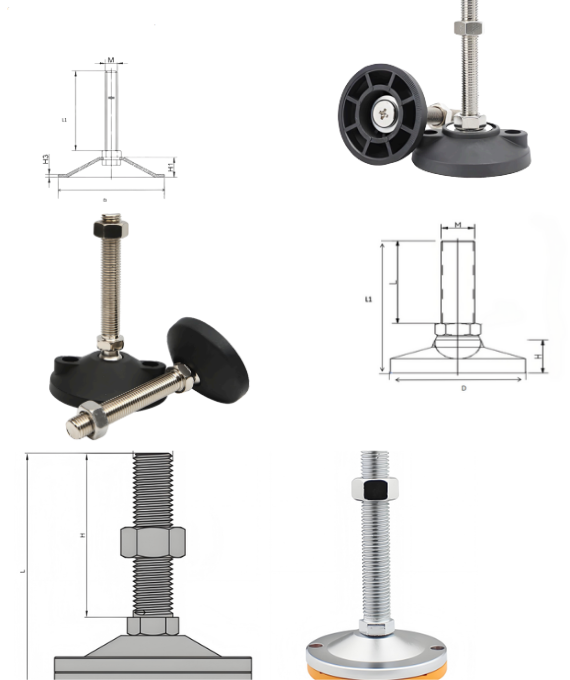

A machine foot—also known as a support foot, base foot, or leveling foot—is a critical mechanical component that provides a stable foundation for industrial equipment. Whether fixed or adjustable, machine feet help maintain equipment balance, absorb vibration, and ensure safe operation.

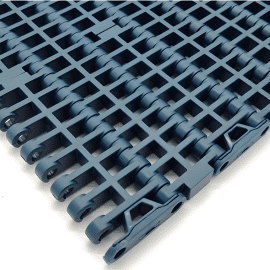

Our full series includes fixed foot, adjustable foot, and adjustable leveling feet configurations, covering everything from lightweight automation machines to heavy-duty presses. Materials include stainless steel, carbon steel, and food-grade nylon, with optional anti-slip or shock-absorbing bases.

Why Choose Stainless Steel Leveling Feet for Food Grade Lines?

In food processing environments, every component must meet strict sanitation standards. In addition to providing structural support, our machine feet offer several key benefits for industrial users:

Superior Load Capacity: Crafted from reinforced 304 stainless steel, these feet can support the heaviest integrated systems. Therefore, you don’t have to worry about structural sagging or thread failure over time.

Precision Leveling: The adjustable threaded rod allows for micro-adjustments on uneven factory floors. Moreover, this ensures that your conveyors and weighers are perfectly horizontal, which is critical for weighing accuracy.

Vibration Dampening: Our designs minimize the transfer of mechanical vibration to the floor. As a result, your sensors and load cells remain stable, delivering more consistent data during high-speed operations.

Designed for Hygiene and Easy Cleaning

Bacteria often hide in the threads and bases of low-quality machine components. For this reason, we have engineered our machine feet with a “washdown-friendly” philosophy.

Thread Protection: Many of our models feature covered threads to prevent debris accumulation. Specifically, this reduces the time your team spends on deep-cleaning the base of the machines.

Corrosion Resistance: The full stainless steel construction withstands aggressive cleaning agents used in meat and poultry plants. Consequently, they will not rust or degrade even after years of daily washdowns.

Machine Foot Types & Specification

1. Fixed Foot (Standard & Nylon Base)

- Thread sizes: M8–M24

- Load range: 500–5000 kg

- Base materials: carbon steel, SUS304, nylon fixed foot (PA66)

- Application: general-purpose support for stable machinery

- Finish: zinc-plated, polished, or anodized

- Budget-friendly and widely used

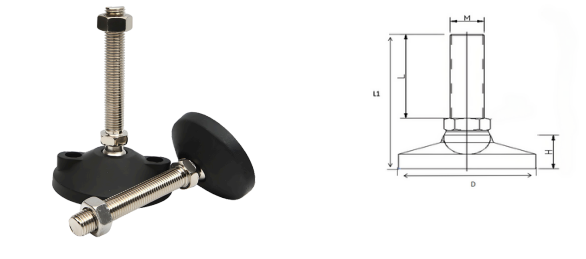

2. Adjustable Foot (Straight or Swivel Base)

- Thread sizes: M10–M24

- Load range: 800–4000 kg

- Height adjustment: 15–100 mm

- Swivel angle: ±10°–30° (optional)

- Application: leveling equipment on uneven or sloped floors

- A versatile adjustable leveling feet option for conveyors, platforms, or automated lines

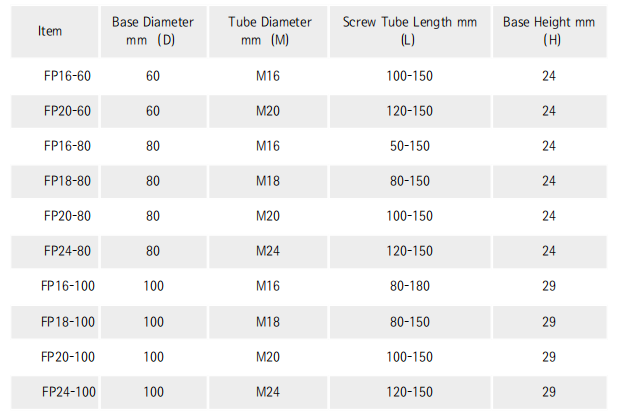

3. Heavy-Duty Machine Foot

- Thread sizes: M16–M30

- Load range: 2000–8000 kg

- Features: thickened base, dual locking nuts

- For CNC machines, hydraulic presses, heavy packaging or printing equipment

- Optional: stainless steel rod + oil-resistant rubber base

Material Highlights

| Material | Benefits | Application |

|---|---|---|

| SUS304 Stainless Steel | Rust-proof, food-safe, high temp (up to 400°C) | Food, pharma, cleanroom |

| Q235 Carbon Steel | Excellent strength-to-cost ratio | General factory equipment |

| PA66 Nylon Base | Lightweight, anti-static, no floor scratching | Electronics, textile, automation |

| Rubber / PU Pads | Anti-slip, oil-resistant, absorbs shock | Printing, CNC, packaging |

Where Machine Foot Matters Most

| Industry | Machine Foot Use Case |

|---|---|

| Packaging Equipment | Stabilizes high-speed VFFS & Conveyors. |

| CNC & Milling Centers | Reduces vibration for higher precision |

| Food Processing | Cleanable stainless machine foot for hygiene-critical areas |

| Printing | Prevents micro-vibration from affecting print quality |

| Automation | Leveling across modular platforms and robot bases |

| Electronics | Nylon fixed foot avoids electrostatic buildup and floor damage |

Installation & Support

- Easy-to-install threaded design

- Lock nuts available for vibration-prone systems

- Non-marking PU pads ideal for epoxy, tile, and clean floors

- Technical drawings and load charts available upon request

- What Is an Adjustable Foot?

An adjustable foot is a specialized type of machine foot designed to provide height regulation and stability for industrial equipment, especially when installed on uneven or sloped flooring. It consists of a threaded stem and a base plate, which may be fixed or equipped with a swivel ball joint for multi-angle adaptation.

Also known as adjustable leveling feet, these components allow precise height adjustment to level your machine while minimizing vibration and stress on structural components.

This models are the go-to option for vertical form-fill-seal (VFFS) machines, weighing platforms, conveyor frames, and working platforms used in hygienic processing environments.

Related Product

Conclusion

Even the smallest part plays a role in your line’s uptime. By investing in professional-grade machine leveling feet, you protect your equipment and ensure a safe, hygienic production environment.

“Need to move your equipment frequently? Explore our [Industrial Casters/Wheels] for mobile packaging units.” Contact us Today .

A fixed foot provides stable support without height adjustment, ideal for flat, even floors. An adjustable foot allows fine-tuning of height and leveling—especially helpful for machines installed on uneven ground or requiring precise alignment.

It depends on the model. Our machine foot range supports from 500 kg (nylon fixed foot) up to 8000 kg (heavy-duty adjustable leveling feet). Always choose a model with 1.5–2x safety margin over your actual load.

Yes. We offer machine foot models made of SUS304 stainless steel with polished surfaces and FDA-grade pads—perfect for food processing, pharmaceutical, and medical applications.

Simply screw the threaded rod into your equipment’s mounting hole. For adjustable feet, use a locking nut to secure the height after leveling. Swivel base versions auto-adapt to uneven surfaces for fast alignment.

Our standard machine foot options include:

Carbon steel for general use

SUS304 stainless steel for corrosion resistance

Nylon fixed foot for lightweight, anti-static needs

Rubber or PU base for anti-slip and vibration control

Absolutely. We can customize thread size, base diameter, swivel angle, surface finish, logo marking, and even pad material to meet your application needs.

Yes. Our heavy-duty adjustable leveling feet and certain fixed models allow pad replacement or upgrading without removing the entire foot.

With proper use, our machine foot systems can last over 5–10 years. All components undergo fatigue, salt spray, and vibration testing to ensure long-term performance.

Contact us with your equipment weight, number of mounting points, floor condition, and environmental factors. Our team will recommend the optimal adjustable foot or fixed foot model based on your needs.