Efficient & Stable Vertical Sealing Jaws for VFFS Machines | B2B Solutions

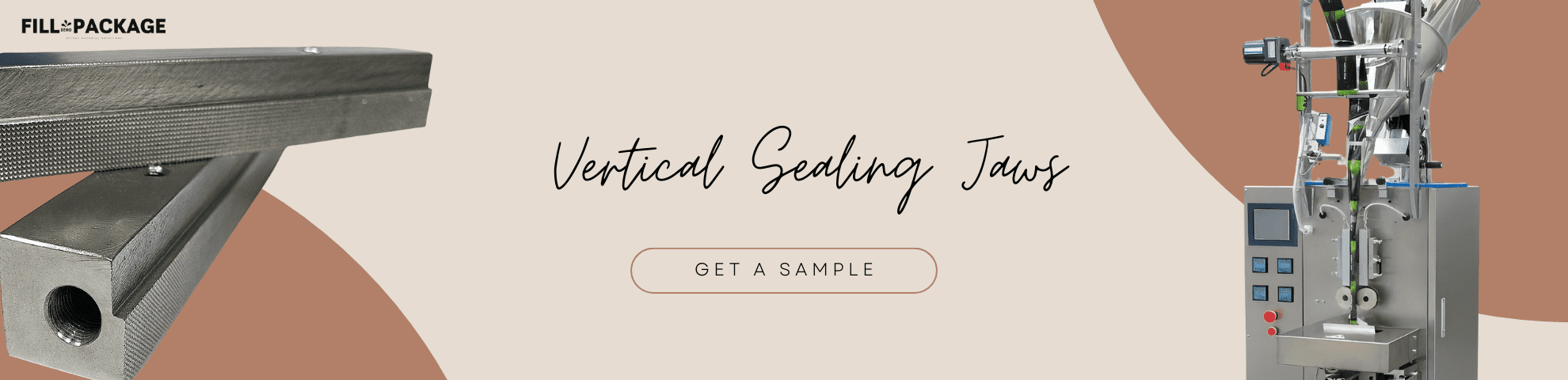

Product Overview: The Final Mile to a Perfect Package

Are Your Customers Troubled by These Vertical Seal Problems?

End-User Pain Point | Root Cause Analysis | Our Solution: The High-Performance Vertical Sealing Jaw |

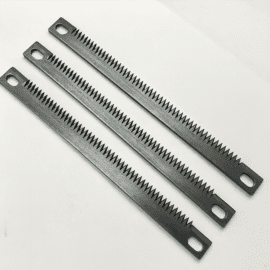

Leaky or weak vertical seals | Worn-out serrations (teeth) on the sealing jaw, uneven pressure, or unstable temperature. | Precision-Machined Serrations: We use CNC engraving to ensure sharp, consistent teeth for uniform pressure and a perfect weld. |

Film burning or tearing | Localized overheating on the heat sealer bar; carbon buildup or film residue. | Superior Materials & Anti-Stick Coating: We use materials with excellent thermal conductivity (Stainless Steel/Copper) and offer an optional Teflon anti-stick coating to prevent film buildup and reduce waste. |

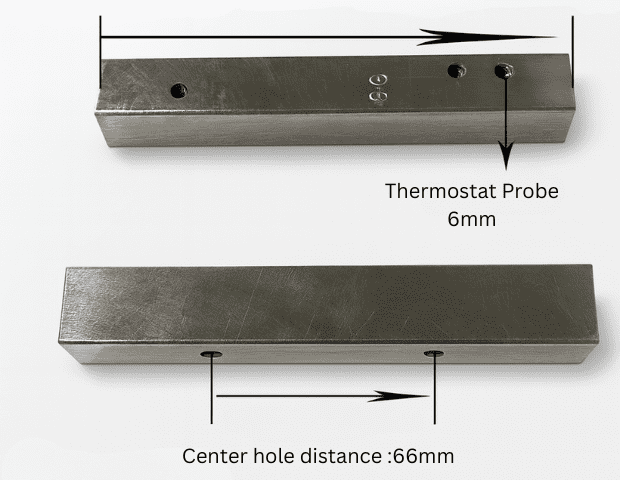

Misaligned or wrinkled seals | Low installation accuracy or deformation of the bag sealing clamp after prolonged use. | High-Strength Base Material & Precise Mounting: Made from high-strength stainless steel or copper that resists deformation. The precise 66mm mounting hole distance ensures perfect alignment with the film pulling system. |

Blackened or burnt seals | Improper cleaning of the sealing jaw surface, leading to residue buildup. | Designed for Easy Maintenance: The smooth, corrosion-resistant material properties make cleaning and maintenance quick and easy, preventing contamination at the source. |

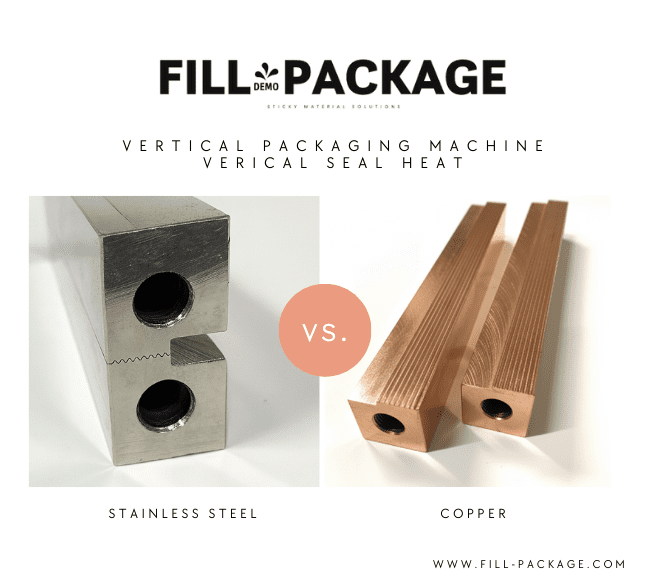

Material Science: Stainless Steel vs. Copper for Your Sealing Jaw

Feature Comparison | SUS304 Stainless Steel (Standard) | H62 Copper (Customizable) |

Thermal Conductivity | Good | Excellent (Heats up faster, more uniform temperature) |

Durability / Hardness | Very High (Excellent wear resistance, longer lifespan) | Good (Softer material, requires more careful maintenance) |

Best-Use Scenario | Versatile, suitable for most packaging films and machine speeds. | For temperature-sensitive films or ultra-high-speed packaging applications. |

Cost-Effectiveness | High | Higher |

What is an Anti-Stick Coating?

This involves applying a layer of Teflon (PTFE) to the surface of the vertical sealing jaw. This coating acts as a protective shield, effectively preventing melted packaging film (especially inner layers like PE or CPP) from sticking to the jaw. It is highly recommended for packaging sticky products or using films prone to melting, as it significantly reduces downtime for cleaning.

Replacement & Maintenance Guide for Your Sealing Jaw

Replacement Tutorial

- Safety Shutdown: Turn off the main power and wait for the vertical sealing jaw to cool down completely.

- Remove Old Jaws: Disconnect the heater cartridge and temperature sensor wires. Use a wrench to loosen the mounting screws and remove the old jaws.

- Clean the Base: Thoroughly clean the mounting base with a cloth, ensuring no residue remains.

- Install New Jaws: Align the new sealing jaws with the mounting holes and tighten the screws. Reconnect the heater and sensor wires.

- Power On & Test: Turn the machine on, set it to the operating temperature, and test the seal quality. Make minor temperature adjustments if necessary.

Maintenance Best Practices

- Daily Cleaning: After shutdown, while the jaws are still warm, use a brass brush or cloth to remove any surface residue.

- Regular Inspection: Weekly, check for significant wear on the serrations and ensure mounting screws are tight.

- Avoid Hard Objects: Never use blades or other hard tools to scrape the jaw surface, especially on a Teflon-coated sealing jaw.

Purchasing & Compatibility

- Ordering Process: Simply provide the required length and material (and specify if you need an anti-stick coating) for a quick quote.

- Compatibility: Our vertical sealing jaws are designed for VFFS machines and are widely compatible with major domestic and international brands. If you are unsure about the size, our technicians will provide expert guidance.

- Performance & Technical Specification

- Mounting Hole Distance: Center-to-center distance of 66mm, compatible with most mainstream VFFS machines.

- Screw Hole: M6 port for temperature sensor/problem

- Surface Finish: Precision wire-cut + CNC-engraved serrations.

- Customization: Copper material, Teflon anti-stick coating, and custom dimensions are available.

Standard Length Specifications

Model | Length (mm) | Material Options | Recommended Application |

VSJ-150 | 150 | Stainless Steel / Copper | Small bags |

VSJ-180 | 180 | Stainless Steel / Copper | Small to medium bags |

VSJ-200 | 200 | Stainless Steel / Copper | Standard sizes |

VSJ-220 | 220 | Stainless Steel / Copper | Standard sizes |

VSJ-250 | 250 | Stainless Steel / Copper | Medium to large bags |

VSJ-280 | 280 | Stainless Steel / Copper | Medium to large bags |

VSJ-320 | 320 | Stainless Steel / Copper | Large bags |

VSJ-350 | 350 | Stainless Steel / Copper | Extra-large bags |

Related Product

Each has its advantages. Copper’s excellent thermal conductivity is ideal for high-speed and precision temperature control. Stainless steel is more durable and cost-effective for most standard applications. We can help you choose the best material for your specific needs.

This is exactly the problem our anti-stick coating solves. Choosing a Teflon-coated vertical sealing jaw will eliminate film sticking and dramatically improve production efficiency.

We offer high-quality replacement parts that meet or exceed OEM standards in performance but at a more competitive price and with more flexible delivery. We specialize in these core wear parts, making us experts.