Filll& Package Bucket Elevator

- Efficient vertical conveying

- High volume tranport

- Low cost

Bucket Elevators

The Z-Type Bucket Elevator is a precision-engineered transport conveyor specifically designed for handling loose, small granular powders and particulate materials. Built for optimal efficiency and product protection, this bucket elevator is commonly used in industries such as food processing, snacks, agriculture, pharmaceuticals, and chemicals.

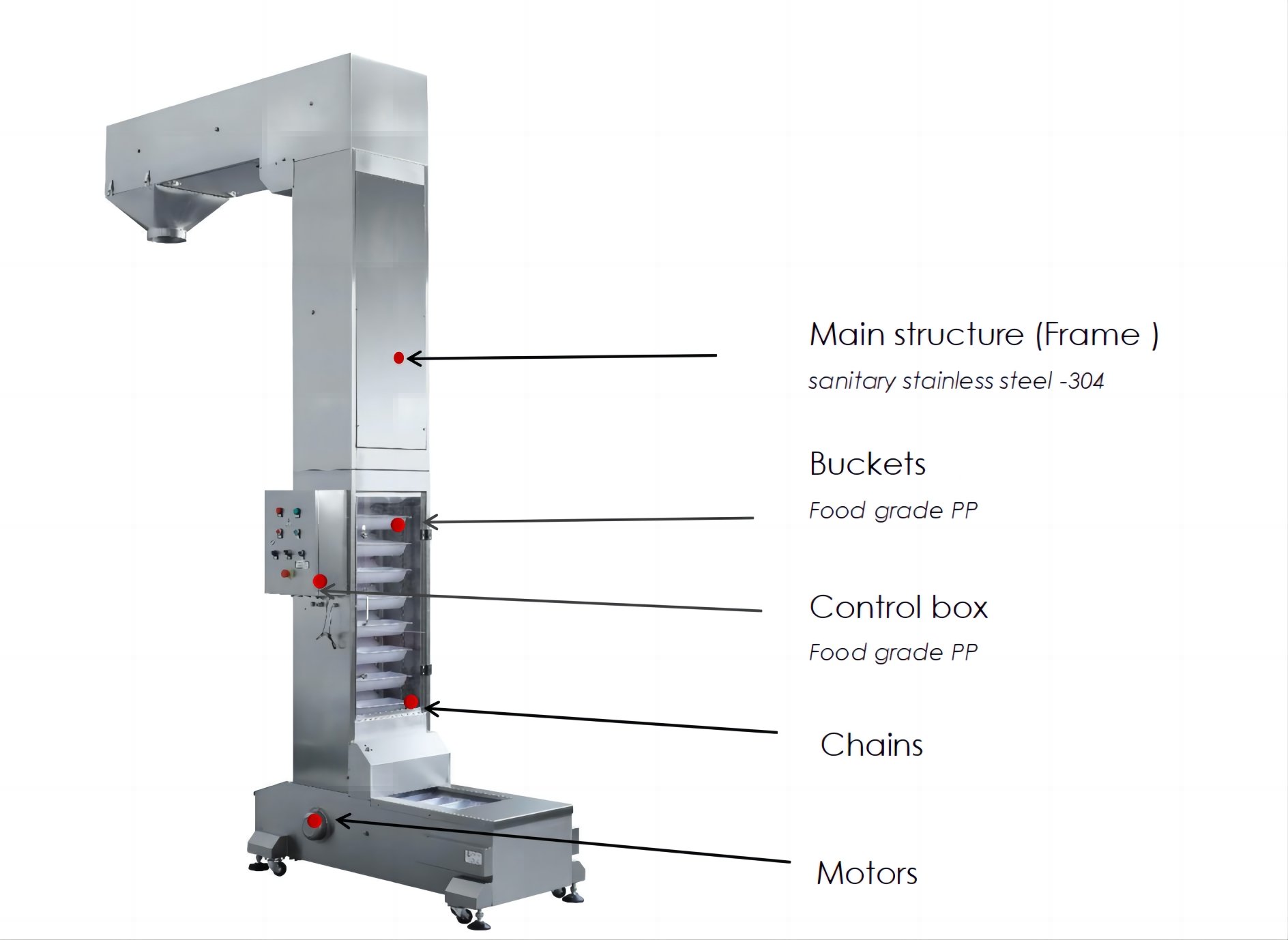

Crafted with a stainless steel frame to ensure durability and hygiene, this elevator features plastic buckets made primarily from PP (Polypropylene), with optional ABS (Acrylonitrile Butadiene Styrene) materials for different application needs. These materials are chosen for their lightweight, corrosion-resistant, and food-safe properties, making them ideal for transporting delicate or contaminant-sensitive products.

The Z-type configuration allows the buckets to move in a vertical and horizontal direction, maximizing space utilization and enabling smooth product transfer from the feeding point to the discharge outlet. Bulk material is evenly distributed into each bucket via a vibration feeder, minimizing spillage and ensuring accurate handling.

Key features of the Z bucket elevator include:

- Continuous and gentle handling of fragile materials

- Customizable bucket sizes based on the type and volume of the material

- Fully enclosed design to prevent contamination

- Chain-driven mechanism supported by pulleys or sprockets at both the head and tail ends

- Seamless integration with upstream feeding systems and downstream packaging equipment

Whether you need to move lightweight powders or small particle-sized materials, this bucket elevator offers a cost-effective

Why Our Bucket Elevators ?

Delivery capacity .Height ,hopper size ,bucket materials ,structure and series of configuration .can be customized according to your application and needs .

Simple and reliable operation ,No need to spend long time to training and learn ,you can start to operate in ashort time.easily & quickly .

Use high quality components, with more than 10 years of experience in buckets elevator manufacturing , long product life, low maintenance cost.

A small investment ,long-lasting conveying solution, lifting products to specified height automatic vertically, with shortest time and high volume.

How Does Bucket Elevator Work?

When you need to move large volume of bulk materials quickly ,bucket elevators are popular choice .Similar to the conveyor belt, the bucket elevators are used to transport bulk materials vertically, the difference is that the bucket elevators uses the buckets on the chain transport materials, it is consisted of machine bed, chains, buckets, motor drive chain to drive the bucket body operation, the object from an end point to the designated location, and then discharge the material.

Each buckets elevator is came with a control box, which includes the following control buttons: work ,run ,stop, run, emergency stop,adjustable speed,automatic/manual and inching, easy and convenient to operate. The control panel has two single cables used to connected with the multihead weighers, which ‘s automatically control the feeding quantity of the Z-bucket conveyor through sign form weighers, and automatically feed and stop.

How To Choose The Right Bucket Elevator ?

Generally ,These are main factors decide to choose bucket elevators .1.the form of materials. it should be bulk solid ,small block or powder .2 the characteristics of material .whether the material is sticky?corrosive ? dry or wet ?3.Delivery volume ,amount of materials to be transported per day ,per hour or per minute to calculate the bucket required ,The standard buckets is 1.6L .which can be increased or reduced according to your needs . if you still have any questions .Our professional team will give you a more detailed explanation.

Bucket Elevator Application

Bucket elevators can handle many kinds of raw materials, so it is widely used in different industries, Generally speaking, z type bucket elevator is suitable for handling bulk materials that flow easily, and it should be used most in food production or processing plants, The most common materials include:rice and grains,Snack Food, biscuits, candies, fruits and vegetables, powder (wash powder, sugar) seafood and so on.

However, the single bucket elevator is more suitable for viscous materials with a little water or oil, which are not easy to flow, such as fresh meat, cheese, fast food, etc.

Not sure which kind bucket elevator suitable for you .contact us and we will be more than happy to help.

We Maybe The Right Bucket Elevator Manufacturer You Are Looking For.

According to the material situation and production requirement of each customer, provide different types of bucket elevator, build the bucket elevators according to the actual needs, to handle the specific situation of materials, which can ensure that bucket elevator can better deal with material transportation and packaging problems during production.

In addition to human damage.one-year warranty.at the same time our components are sufficient to support your urgent delivery, free training for all customers in need. Send the installation instruction video before shippment, if the customer needs to install, our technician will come to support.

Not only experience for bucket elevators, but also we have more experience in building full packaging system. As the transportation part of the automatic packaging system, it can not only focus on its own good operation, but more is how to cooperate with the operation of the whole system.

Our materials are according to high quality standards. At the same time, many parts are universal parts and can be bought locally, to ensure that you low maintenance.reliable handing solution

Feature Box

- Standard Discharge Height: 3200m (customized other size )

- Standard In-Feed Length: 860mm

- Variable Speed Control: As required

- Bucket Selection: 2L, 4L & 6L

- Machine type: Z type and multiple discharge outlets

- Frame Material: Stainless Steel 304

- Bucket Material :Food grage plastic (PP)

- Machine frame : Stainless steel #304

- Hopper size : 30L-100L (customize )

- Production capacity : 2.5-6m³/H

- Machine Height : 1000-6000mm (customize )

- Conveying Height : 1000-5000mm (customize)

- Voltage : Three-phase 220V~380V

- Power supply : 1.8kw

Related Product

How to install the bucket elevator ?

Follow is some details to take a note .

The Z-Type elevator features a vertical and horizontal movement path, making it ideal for facilities with limited floor space. Its design ensures gentle handling and a fully enclosed transport system.

The buckets are made from food-grade plastic materials—primarily PP (Polypropylene) or ABS. These plastics are durable, lightweight, and resistant to corrosion and chemicals.

This bucket elevator is best suited for loose, small particulate materials such as rice, grains, nuts, dry powders, small candy pieces, seeds, and similar products.

Yes, the elevator is designed for seamless integration with vibration feeders, multihead weighers, and automatic packaging systems, streamlining the entire production line.

A vibration feeder ensures consistent and even distribution of bulk material into each bucket, optimizing the loading process and reducing waste or spillage.