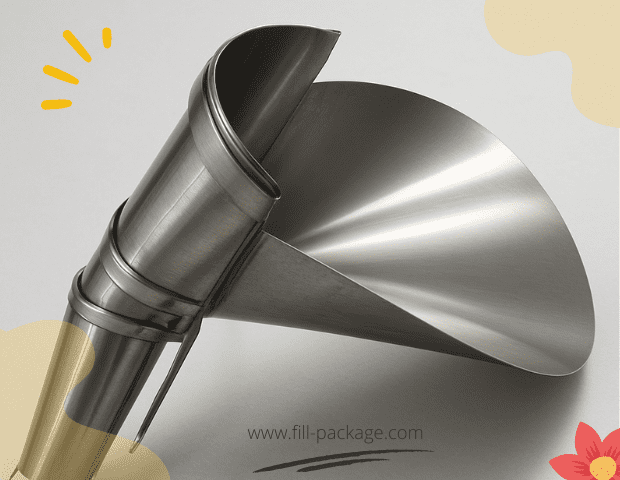

Designed for Powder & Liquid Packaging, Say Goodbye to Film Jamming and Material Clogging

Specialized Bag Former vs. Conventional Collar-Type Former

Feature | Specialized Bag Former (for Sachets) | Conventional Collar-Type Former |

Core Structure | Flexible Guide Plate + Guide Tube | Fixed Collar + Forming Tube |

Key Advantage | High Adaptability, Anti-Clogging, Anti-Jamming | Simple Structure, Lower Cost |

Applicable Materials | Powders, Liquids, Sauces, Small Granules | Solid Granules, Puffed Foods, Hardware |

Applicable Machines | DXDK series powder packers, liquid filling machines | Most general-purpose VFFS machines |

Core Functions & Design Highlights

Function | Design Highlight | Your Benefits |

Superior Adaptability | Flexible Guide Plate & Tube: Allows for slight adjustments to automatically fit different outlet diameters. | Versatility: No need to frequently change formers for minor size differences, reducing spare parts costs. High Compatibility: Easily matches various packaging machine brands. |

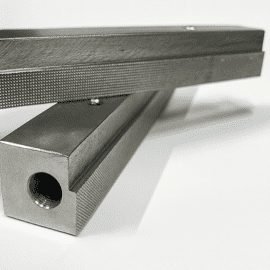

Ultimate Smoothness | Guide Strips Design: Ultra-low friction strips inside the former guide the film smoothly. | Eliminates Film Jamming: Ensures stable operation even with sticky or thin films, reducing downtime. |

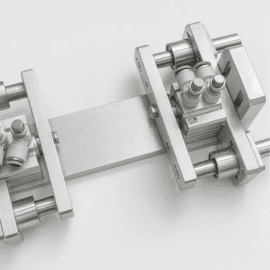

Stable Installation | Rotary Locking Mechanism: An innovative locking system for both quick installation and absolute stability during high-speed operation. | Increased Efficiency: Reduces changeover and adjustment time by over 50%. Safe & Reliable: Prevents displacement caused by vibration. |

Smart Integration | Optional ARM Control System Interface for seamless connection with the packaging machine’s smart control system. | Enhanced Automation: Supports functions like automatic weighing, bag making, and waste discharge for truly intelligent production. |

Typical Application Scenarios

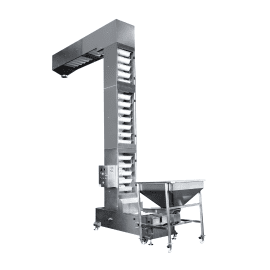

Scenario 1: Fully Automatic Powder Packaging

- Applicable Machine: DXDK series automatic weighing and packing machines

- Materials: Milk powder, coffee powder, medicinal powder, seasonings, etc.

- Pain Point Solved: The unique design uses gravity to guide materials directly into the bag, reducing dust and residue on the inner walls of the stainless steel forming shoulder.

- Packing Accuracy: Achieves packing accuracy up to ±0.1g when paired with a film pulling wheel system.

Scenario 2: Liquid/Sauce Filling

- Applicable Machine: Nasal spray filling machines, sauce packing machines

- Materials: Nasal sprays, shampoo, ketchup, salad dressing, etc.

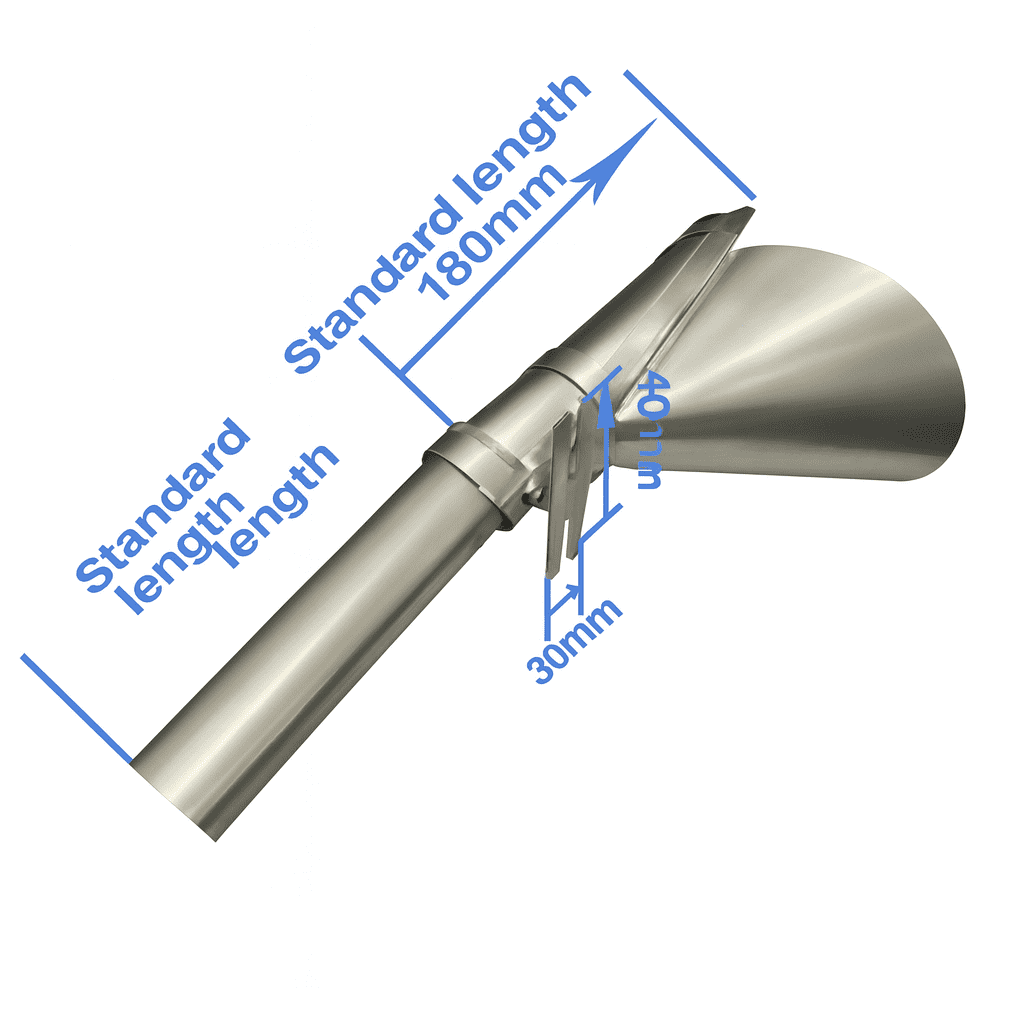

- Pain Point Solved: The “trunk” part of this stainless steel feeding pipe tube cylinder bag former can extend into the bag for bottom-up filling, effectively preventing splashing and foaming.

- Qualification Rate: Achieves a product qualification rate of over 99% when integrated with a precise filling system.

B2B Partnership & Services

- OEM/ODM Customization: We provide full-process customization services from design to production based on your machine models and technical requirements.

- Bulk Price Advantage: The larger the order, the better the price. Inquire now for bulk discounts.

- Stable Supply Chain: We have a mature production system to ensure your orders are delivered on time, with guaranteed quality and quantity.

- Technical Support: Our engineering team provides comprehensive technical support, including selection, installation, and debugging.

How to Choose the Right Bag Former?

Example:

- Your desired bag width is 100mm.

- The standard side seal width is typically 10mm.

- Required Film Width = (100mm x 2) + (10mm x 2) = 220mm.

- Based on the table above, you should choose the SF-M240 (200mm-240mm) bag former.

- Bag Former Specifications for Sachet Machines

Model (SKU) | Applicable Film Width | Recommended Bag Width Range |

FP-S090 | 50mm – 90mm | Approx. 15mm – 35mm |

FP-S140 | 100mm – 140mm | Approx. 40mm – 60mm |

FP-M190 | 150mm – 190mm | Approx. 65mm – 85mm |

FP-M240 | 200mm – 240mm | Approx. 90mm – 110mm |

FP-L290 | 250mm – 290mm | Approx. 115mm – 135mm |

FP-L340 | 300mm – 340mm | Approx. 140mm – 160mm |

FP-XL390 | 350mm – 390mm | Approx. 165mm – 185mm |

FP-XL440 | 400mm – 440mm | Approx. 190mm – 210mm |

FP-XXL490 | 450mm – 490mm | Approx. 215mm – 235mm |

Related Product

Need Custom Stainless Steel Forming Shoulder Parts?

Generally, no. Their mounting bases and integration methods differ. This sachet packaging machine former is typically used for specific powder or liquid machine models, while the collar-type is more universal. Please confirm your machine type before purchasing.

We use high-quality flexible stainless steel that has passed tens of thousands of fatigue tests. Under normal use, the lifespan of the flexible structure is the same as the main body of the former, lasting at least 2-3 years.

Yes, custom non-standard orders are one of our core strengths. We can meet your needs for special diameters, angles, or materials. The MOQ for standard products is 1 piece, and we welcome you to request a sample for testing.