Vertical Form Fill Seal Machine

A Vertical Form Fill Seal (VFFS) Machine automates vertical bag forming, product filling, and sealing for industrial packaging lines, ideal for food, powders and granular goods.

VFFS Machines

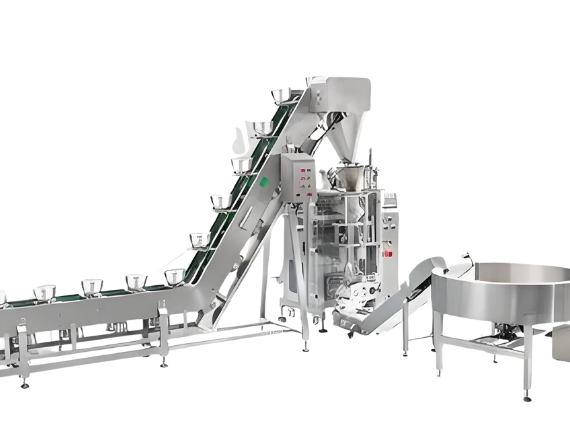

Vertical Form Fill Seal (VFFS) machines are used to vertically turn the film into a bag. It is used in most industrial productions, including low, medium and high-speed filling applications in the food and non-food industries. It usually installed in the last stage of the production line, behind the weighing machine, which is the packaging stage. Their role is to package the productso n the production line for easy transportation, storage, and sales.

Vffs packaging machine working principle is to use a single-film coil to weld the package in three places, two horizontal fork welding and one vertical vertical welding. It should be mainly used in solid loose products, granular products, liquid beverages, etc., and it can be used everywhere in industrial packaging.

Vertical Form Fill Seal Machine For Sale

A few popular products for your reference,They are suitable for different applications.

Benefits In Details

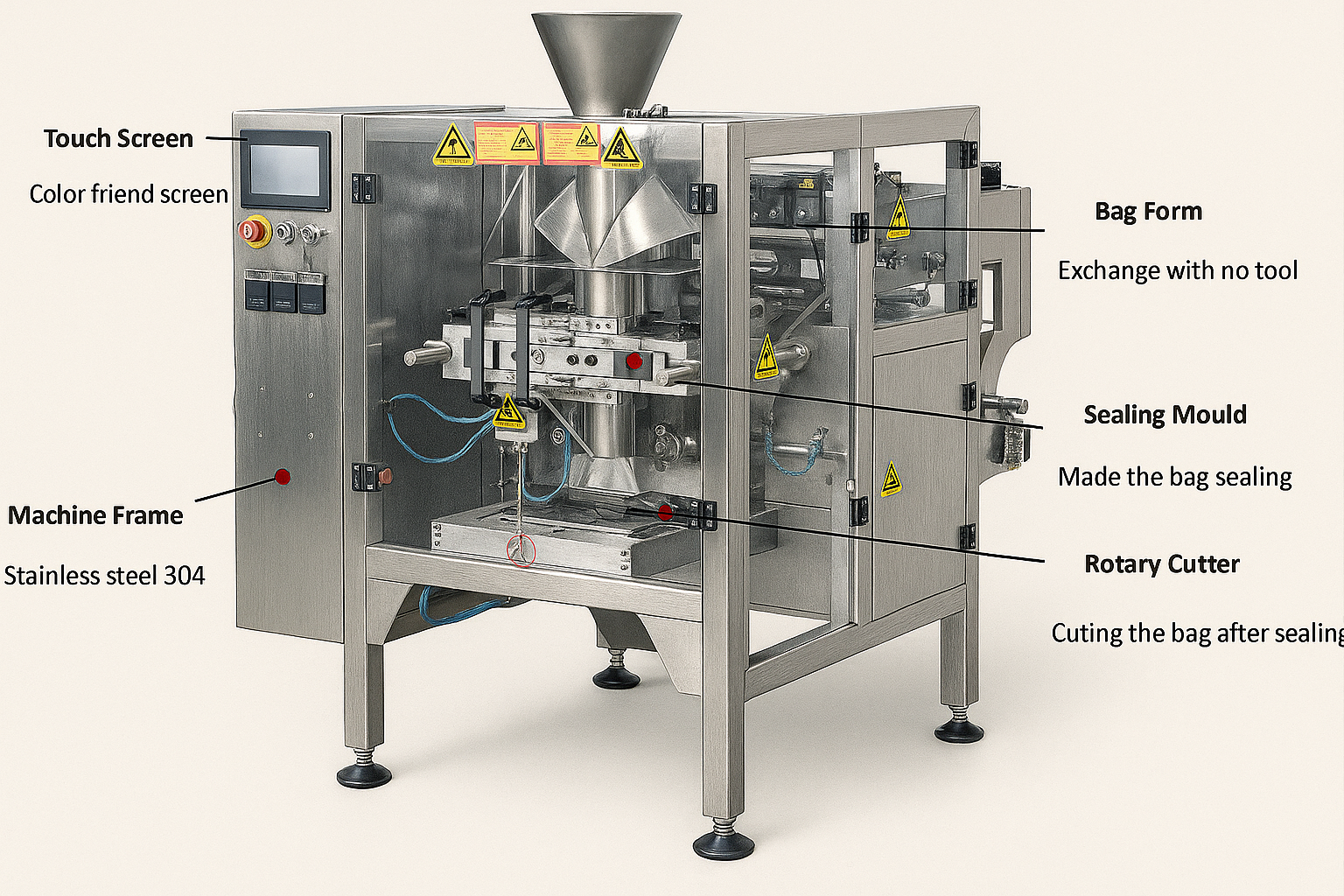

Quickly adjust or change bags of various sizes with no tools , all processes can be completed in a few minutes.the speed can be adjusted at continuous motion working .

.

A variety of functional packaging combinations to create the most suitable packaging style for you, including four-side sealed bags, bottom gusseted bags, standard pillow-shaped bags etc.

Easily integrated into existing production line , simple installation operations can be added to the current combination scales, conveyor belts, and checkweighers.

Durable stainless steel body, not only suitable for industrial products, but especially suitable for food with strict hygienic cleaning conditions

How do Vertical Form Fill Seal Machine Wrok?

The VFFS is vertical packaging machine consists of the following parts: filling area, forming area, film pulling and alignment area, sealing and cutting area, Vertical form fill seal machine diagram as shown in the picture.

The working principle of the general vertical packaging machine is as follows:Prepare to pull the film. The packaging material is generally PE, PP and other materials. It is prefabricated into a roll-shaped film according to the size and pattern you specify. The film is pulled and tensioned thanks to rollers and a weighed pivot arm. It Usually placed at the back of the machine.

The bag is formed.The packaging film is laid flat and tensioned onto the former, the film is wrapped around the forming tube and pulled along the tube, just after forming, some pull down straps are installed to move the film and let it pull into a tube shaped film bag.

Vertical Sealing.When the packaging material is well wrapped on the molding and enough length , side sealing can be performed. When calculating the width of film, an extra part of the film width have inclued so that the width of the bag when it is formed is If there is overlap, use sealing pliers or sealing strips to weld the overlapping part of the overlapping materials to form a side sealing.

Bottom sealing.before the product is injected after the side sealing is completed, the bottom sealing is done by another pair of sealing rods, which can weld the material by pressure and heat.

Product filling.The product falls through the forming tube and falls inside the bag.

Top seal & cut.Once the product is dropped, the performing bottom sealing jaws are activated again, creating the top seal and when closing the bag it is cut and dropped, usually with a conveyor belt, to the next packaging step.

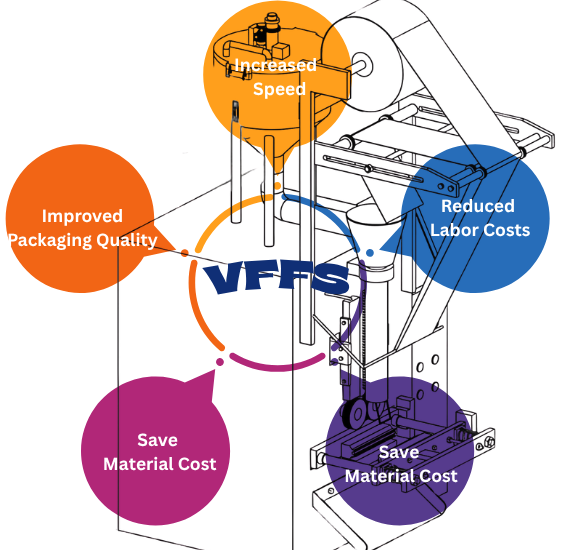

The Core Benefits of Integrating a VFFS Machine

Investing in a vertical form fill seal machine provides a multitude of benefits that directly impact your bottom line and operational efficiency.

- Increased Production Speed: VFFS machines can package products at speeds far exceeding manual or semi-automated methods, with some models producing over 100 bags per minute.

- Reduced Labor Costs: By automating the entire bagging process, you can significantly reduce the need for manual labor, allowing you to reallocate staff to higher-value tasks.

- Significant Material Cost Savings: Using film rollstock is substantially more economical than purchasing pre-made bags, often resulting in material cost savings of 20-50%.

- Improved Packaging Quality and Consistency: The automated process ensures that every bag is formed, filled, and sealed to the exact same specifications, improving product protection and brand presentation.

- High Versatility: A single VFFS machine can often be adapted to handle different products, bag sizes, and film types with relatively quick changeovers.

- Smaller Footprint: The vertical design of these machines typically requires less floor space than other packaging solutions like horizontal form fill seal (HFFS) machines.

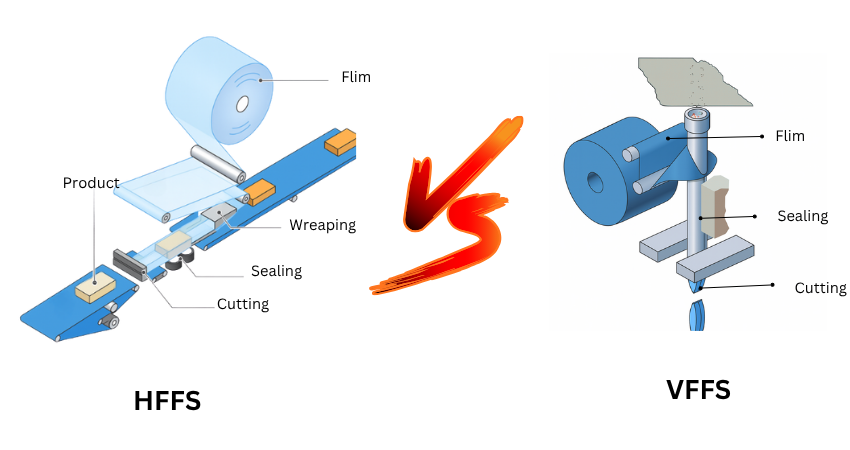

VFFS vs. HFFS: Which Packaging Machine is Right for You?

While exploring packaging automation, you may encounter another term: Horizontal Form Fill Seal (HFFS) machine. Understanding the core difference is crucial to identifying the best solution for your product.

| Feature | Vertical Form Fill Seal (VFFS) | Horizontal Form Fill Seal (HFFS) |

|---|---|---|

| Operating Principle | Uses gravity to fill products vertically. | Fills products horizontally into a pre-formed pouch. |

| Ideal Products | Loose, granular, powder, or liquid products (chips, coffee, sugar, sauces). | Single, solid, or flat items that are difficult to drop (cookies, soap bars, medical devices). |

| Footprint | Smaller, more compact footprint, saving valuable floor space. | Larger, more linear footprint. |

| Best For | Free-flowing products where speed and efficiency are key. | Products that need careful handling or placement. |

In short, the choice between a vertical packaging machine and a horizontal one begins with your product’s characteristics. If your product is free-flowing, a VFFS machine is almost always the more efficient and cost-effective option.

VFFS Main Models & Features

| Model | Application Range | Features |

|---|---|---|

| Small Vertical Packaging Machine | Small packages of particulates, powders or liquids (e.g. coffee powder, seasonings, pharmaceuticals) | Compact structure and small footprint; supports back seal, three‑side seal and other bag types; ideal for start‑ups or pilot lines |

| High‑Speed Vertical Packaging Machine | Medium‑ to high‑volume production lines for foods, snacks and small granulated products | Speeds of over 100 bags per minute; automatic film tracking and edge correction; optional printing devices (date codes, barcodes, etc.) |

| Heavy‑Duty Vertical Packaging Machine | Heavy or bulky products such as pet food, hardware parts and frozen foods | Reinforced frame and powerful servo drive; capable of packaging 5–20 kg bags; supports gas flushing for extended shelf life |

How to Choose the Right VFFS Machine?

Product characteristics: Consider the product’s shape, size, weight, texture and viscosity, since these factors influence the dosing method and whether a VFFS machine is suitable. Products that are very large or highly viscous may require alternative solutions.

Bag type & material: Determine whether you need a pillow‑style (back center seal), three‑sided seal, block bottom, gusseted bag or other format. Choose appropriate packaging materials—such as polyethylene, polypropylene, laminate films, foil or paper—to ensure a secure seal and product protection.

Production capacity & speed: Assess your throughput requirements and target production speed, then select a VFFS model that meets or exceeds these demands.

Reliability & maintenance: Opt for a machine that is reliable, requires minimal maintenance and is easy to repair. This helps maintain continuous, stable production.

Cost & budget: Weigh your budget constraints and long‑term operating costs against the machine’s capabilities to identify the most cost‑effective option.

Common Industry Applications

VFFS machines are installed at the end of packaging lines to package products into sealed bags, supporting high speed, flexible bag styles, and efficient production,makes it indispensable across a wide range of industries:

- Food & Beverage: The largest user of VFFS technology for products like potato chips, nuts, candy, coffee, sugar, spices, and frozen foods.

- Pharmaceuticals: For packaging powders, granules, and tablets in precise doses.

- Pet Food: Ideal for packaging dry kibble and treats in bags of all sizes, from small pouches to large, heavy-duty bags.

- Hardware: For bagging small parts like nails, screws, and other components.

- Cosmetics: For packaging liquid samples, powders, and other beauty products.

Blogs About VFFS

Why Your Packaging Line Needs a Vertical Form Fill Seal (VFFS) Machine

How to Choose the Right Vertical Form Fill Seal (VFFS) Machine for Your Production Needs

VFFS vs HFFS: Which Packaging Machine is Right for Your Production Line?

FAQs About VFFS Machines

VFFS machines can handle a wide variety of products including granular, powder, liquid, and solid foods. :contentReference[oaicite:10]{index=10}

The VFFS process includes film unwinding, bag forming, vertical sealing, filling, horizontal sealing, and cutting. :contentReference[oaicite:11]{index=11}

VFFS forms and fills vertically from roll film while HFFS fills horizontally into preformed pouches. :contentReference[oaicite:12]{index=12}

Yes. An optional gas‑flushing system can be installed. By injecting an inert gas such as nitrogen or carbon dioxide to displace oxygen inside the package, the shelf life of the food can be extended.

- Absolutely. Our VFFS machines can be integrated with various printing devices, such as thermal transfer overprinters (TTO), to print date codes, batch numbers, barcodes, and QR codes directly onto the film during the packaging process.

- Bags are sealed using heated sealing jaws that apply both pressure and heat to the film. The temperature and pressure can be precisely controlled to ensure a strong, reliable seal for different types of film materials.

Regular maintenance is key. This includes daily cleaning of contact parts, periodic inspection of wear parts like sealing jaws and knives, and lubrication of moving components. We provide a detailed maintenance schedule with every machine.

Our VFFS machines are compatible with a wide range of heat-sealable films, including polyethylene (PE), polypropylene (PP), laminate films, and metalized films.

Ready to take the next step in automating your packaging line? Contact the experts at Fill&Package today. Our team will work with you to understand your specific needs and recommend the perfect vertical packaging machine to meet your goals and budget.