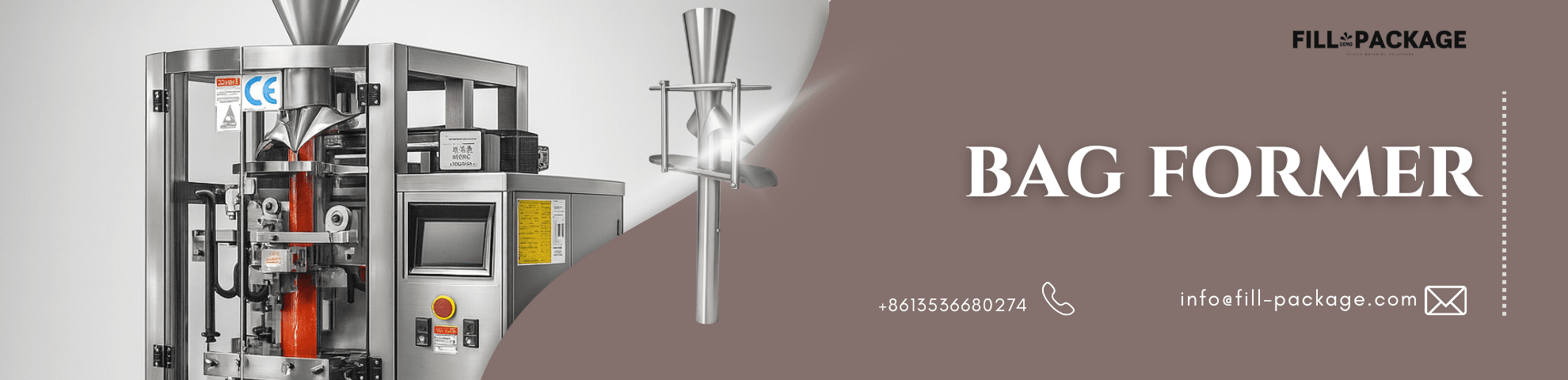

High-Performance VFFS Bag Former | Engineered for Machine Manufacturers & Wholesalers

Product Overview: The Core of Perfect Bagging

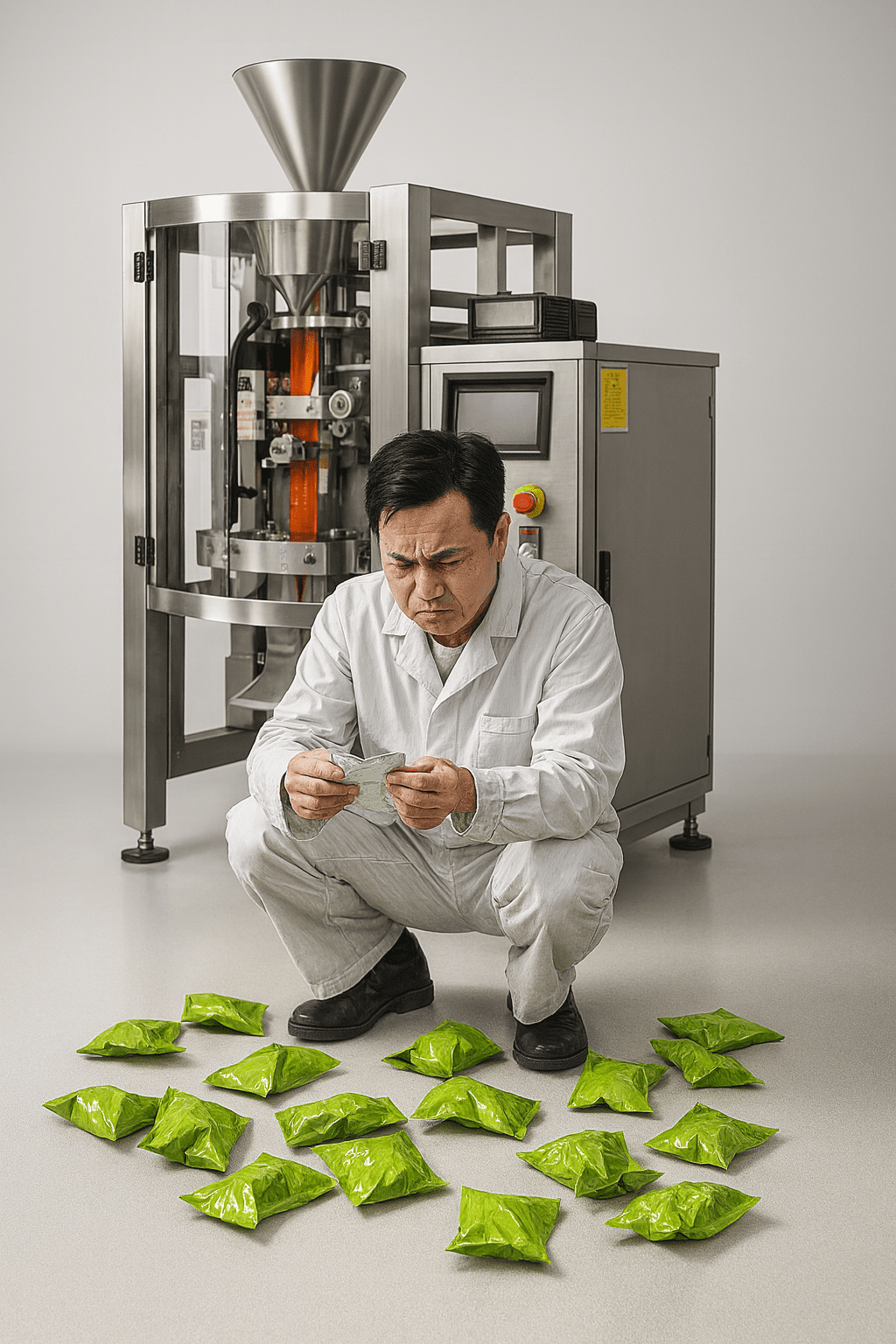

Are Your Customers Complaining About These Common Issues?

End-User Pain Point | Root Cause | Our Solution: The Superior Bag Former Design |

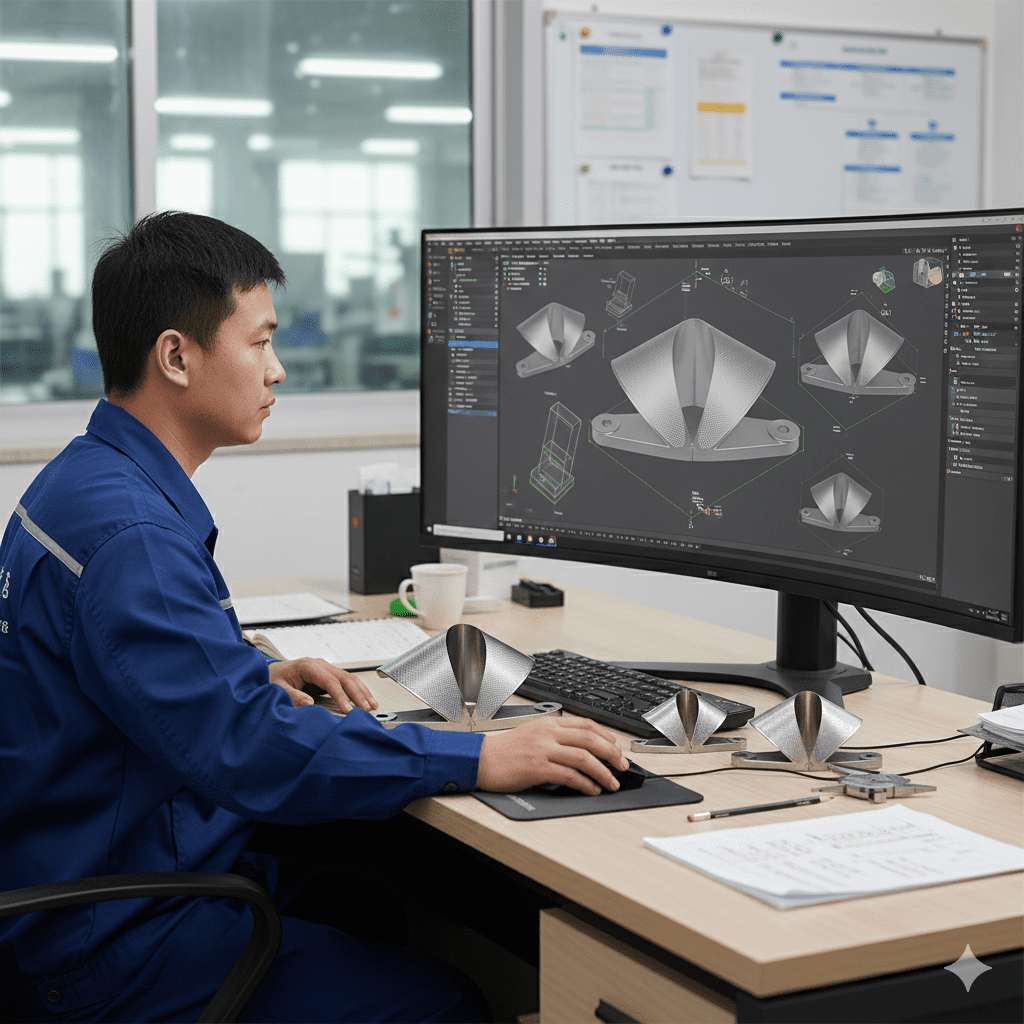

Frequent wrinkles and film distortion | Poorly designed forming shoulder curve, excessive film tension. | Optimized Curve Geometry: We use computer simulations and extensive testing to create the ideal forming shoulder contour, ensuring smooth film travel and minimal friction. |

Inconsistent bag sizes, misaligned seals | Low-precision forming collars, deformation over time. | High-Precision Manufacturing & Premium Materials: Crafted from SUS304 stainless steel with high-precision laser cutting and expert hand-polishing, our bag formers guarantee dimensional accuracy and resist deformation. |

Lengthy debugging after film changeovers | Poor compatibility of the bag former for packing machine. | Universal Compatibility: Our forming tubes and collars are rigorously tested to be compatible with leading domestic and international VFFS machine brands. Custom designs are also available. |

Inability to increase packaging speed | Film fluttering or drifting during the forming process. | Seamless Forming Technology: We utilize advanced seamless shaping and argon arc welding techniques to create an ultra-smooth interior, ensuring stable film tracking even at high speeds. |

Performance Specifications & Dimensions

Key Performance Features

- High-Precision Forming: Accommodates a wide range of film thicknesses (0.02mm – 0.12mm), ensuring consistent and aesthetically pleasing bags.

- Low-Friction Surface: A mirror-polished finish on the forming shoulder minimizes drag, protecting printed films from scratches and damage.

- Modular Design: The bag former assembly is designed for easy installation and maintenance, significantly reducing machine downtime.

- Robust & Durable: Made from premium SUS304 stainless steel, our forming tubes are corrosion-resistant, wear-resistant, and built to last.

Standard Size Specifications (Examples)

Model | Applicable Film Width (mm) | Forming Tube Diameter (mm) | Total Height (mm) |

LF-80 | 80-200 | 50-100 | 200-350 |

LF-150 | 150-300 | 80-150 | 300-500 |

Custom Orders | As required | As required | As required |

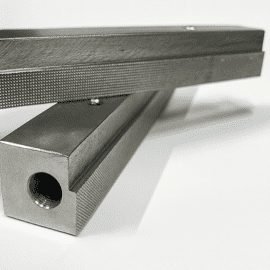

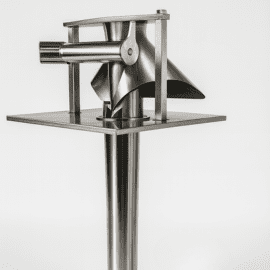

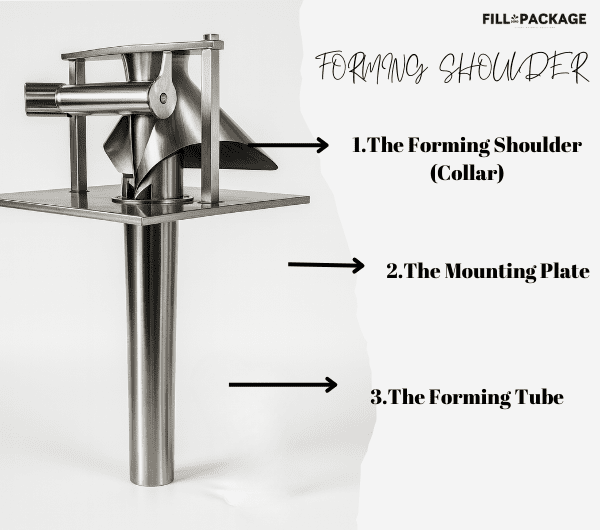

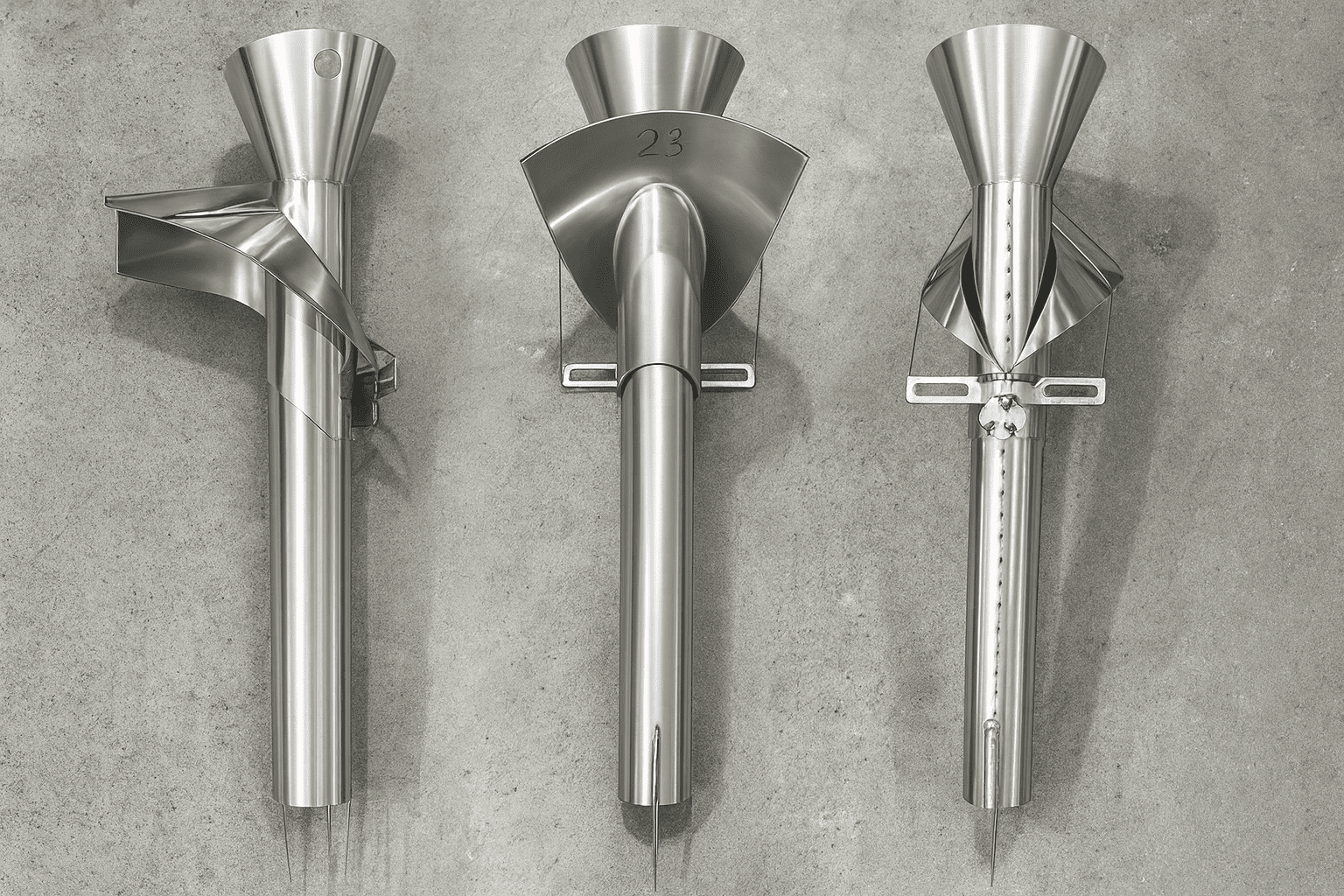

Anatomy of a Bag Former: The Science of Flawless Bagging

Key Component | Design Highlight & Customer Value |

The Forming Shoulder (Collar) | A perfectly contoured forming collar combined with meticulous hand-polishing allows any type of film to glide smoothly, resulting in a perfect bag shape every time. |

The Forming Tube | Specifically designed for your product, this component maximizes product flow and includes high-speed options for seamless integration with weighing systems. |

The Mounting Plate | Engineered to the exact specifications of the machine manufacturer for a perfect fit. Available in aluminum or stainless steel, with options for weight reduction. |

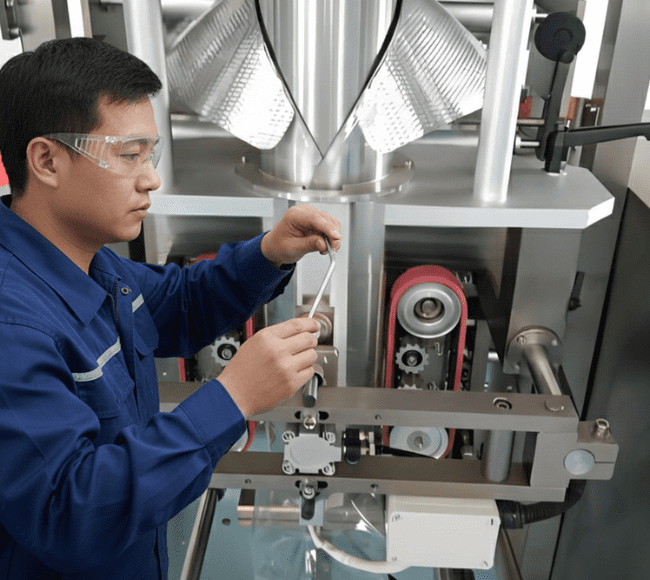

Bag Former Replacement Tutorial

Tools Required

Step-by-Step Replacement Process

Step | Action | Key Considerations |

1. Stop & Power Off | Ensure the machine is completely stopped and the main power is disconnected. | Safety first! |

2. Remove Old Assembly | Use an Allen wrench to loosen the mounting bolts. Gently tap the forming shoulder with a rubber mallet to dislodge it from the support frame. | Avoid using excessive force to prevent damage to the mounting frame. |

3. Clean Mounting Surface | Use a cloth and alcohol to thoroughly clean any film debris, grease, or residue from the mounting surface. | A clean surface is essential for precision alignment. |

**4. Install New Bag Former | Align the new bag former with the positioning holes, slide it smoothly into place, and then evenly hand-tighten all mounting bolts. | Ensure the assembly is seated correctly and not tilted. |

5. Align & Test | Manually pull a section of film through the forming tube and over the forming shoulder. Finely adjust the assembly’s position until the film path is centered, smooth, and free of wrinkles. | This is the most critical step for ensuring quality bag formation. |

Purchasing & Partnership Guide

We offer a streamlined process for our B2B clients:

- Provide Your Specs: Simply give us your VFFS machine model, desired bag style, and film width.

- Technical Confirmation: Our experts will provide free drawing confirmation and model selection advice.

- Fast Production: Standard models are in stock. We promise rapid delivery for custom orders.

- After-Sales Support: We provide comprehensive technical support and a robust warranty.

Compatibility Information

- Leading Chinese Brands: Dasong, Coretamp, Baopack, Zhongke, etc.

- International Brands: Bosch, Ishida, Matrix, Rovema, tna, Hayssen, and more.

Related Product

We provide high-quality replacement parts that use materials and manufacturing processes that are equivalent or superior to OEM standards. Our advantages lie in faster delivery, more flexible customization, competitive pricing, and equally reliable performance.

No problem at all. Just provide your packaging machine brand/model and target bag width. Our technical experts will handle the rest, including design drawings for your final confirmation.

Yes, we welcome OEM/ODM partnerships. We can manufacture forming tubes and shoulders according to your brand requirements, including custom logos and packaging.

Absolutely! We offer highly attractive volume discounts for machinery manufacturers and wholesalers. Please contact our sales manager for a detailed quotation.