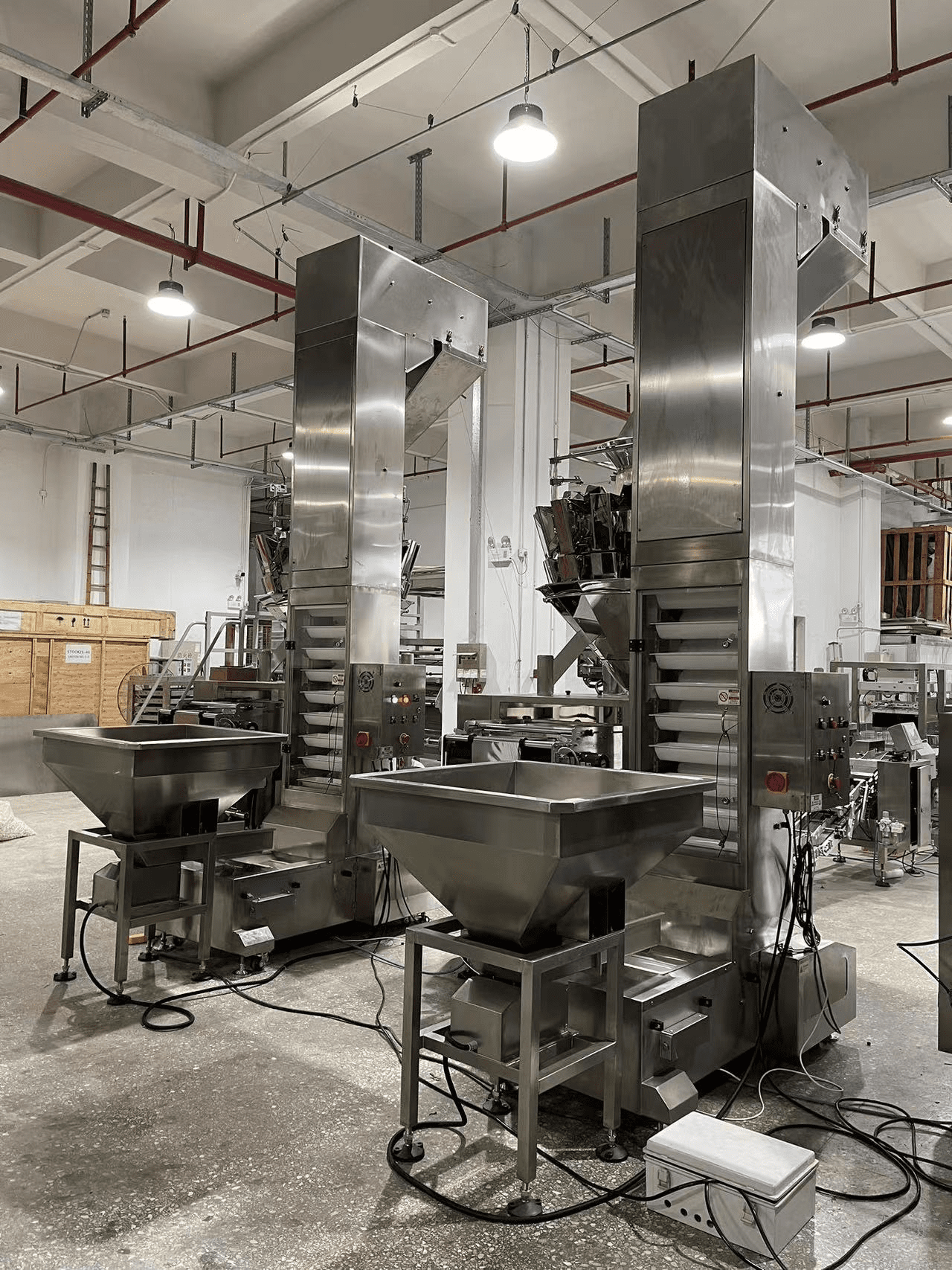

In the world of automated packaging and bulk material handling, the bucket elevator is an indispensable workhorse. It is the go-to solution for gently elevating and conveying a wide range of products—from delicate snack foods and coffee beans to grains and small hardware—to the next stage of the production line, most commonly a multi-head weigher.

While the concept is straightforward, the reliability and efficiency of a bucket elevator depend entirely on the quality and synergy of its core components. For machine manufacturers, selecting the right components is key to building a dependable machine. For parts wholesalers, these are high-demand wear parts. And for food factory maintenance managers, understanding these components is the first step to effective troubleshooting and preventive maintenance.

This in-depth guide will dissect the anatomy of a modern bucket elevator, focusing on its three most critical components: the buckets (hoppers), the roller chain, and the sprockets. We will explore their functions, materials, and designs, and provide practical guidance on selection, maintenance, and knowing when it’s time for a replacement.

Anatomy of a Bucket Elevator: A Deep Dive into Core Components

A bucket elevator is more than just a conveyor; it is a precisely engineered system. Let’s break down the parts that make it work.

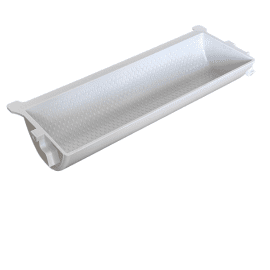

1. The Buckets (Hoppers): The Heart of Material Transport

The buckets are responsible for scooping, carrying, and discharging the product. Their design and material have a direct impact on product integrity, hygiene, and system efficiency.

Bucket Materials: PP vs. ABS

The vast majority of food-grade buckets are made from one of two polymers:

Material | Key Characteristics | Best Use Case |

Polypropylene (PP) | Excellent chemical resistance, good fatigue strength, very cost-effective. More flexible than ABS. | The industry standard for most food applications, especially in environments with frequent washing or exposure to cleaning agents. |

Acrylonitrile Butadiene Styrene (ABS) | Higher rigidity and impact strength, better dimensional stability, and a glossier finish. | Applications requiring greater stiffness, or for products that are particularly abrasive. Often seen as a premium option. |

Bucket Sizes and Surfaces

- Sizes: Buckets come in various standard capacities, with the most common being 1.8L (often interchangeable with 2.0L) and 3.8L (interchangeable with 4.0L). The choice depends on the required throughput (kg/hour) and the density of the product.

Surfaces:

- Smooth/Flat Surface: Ideal for most products and the easiest to clean.

- Textured/Patterned Surface: Used for sticky products (like gummy candies) to reduce surface tension and ensure a clean discharge.

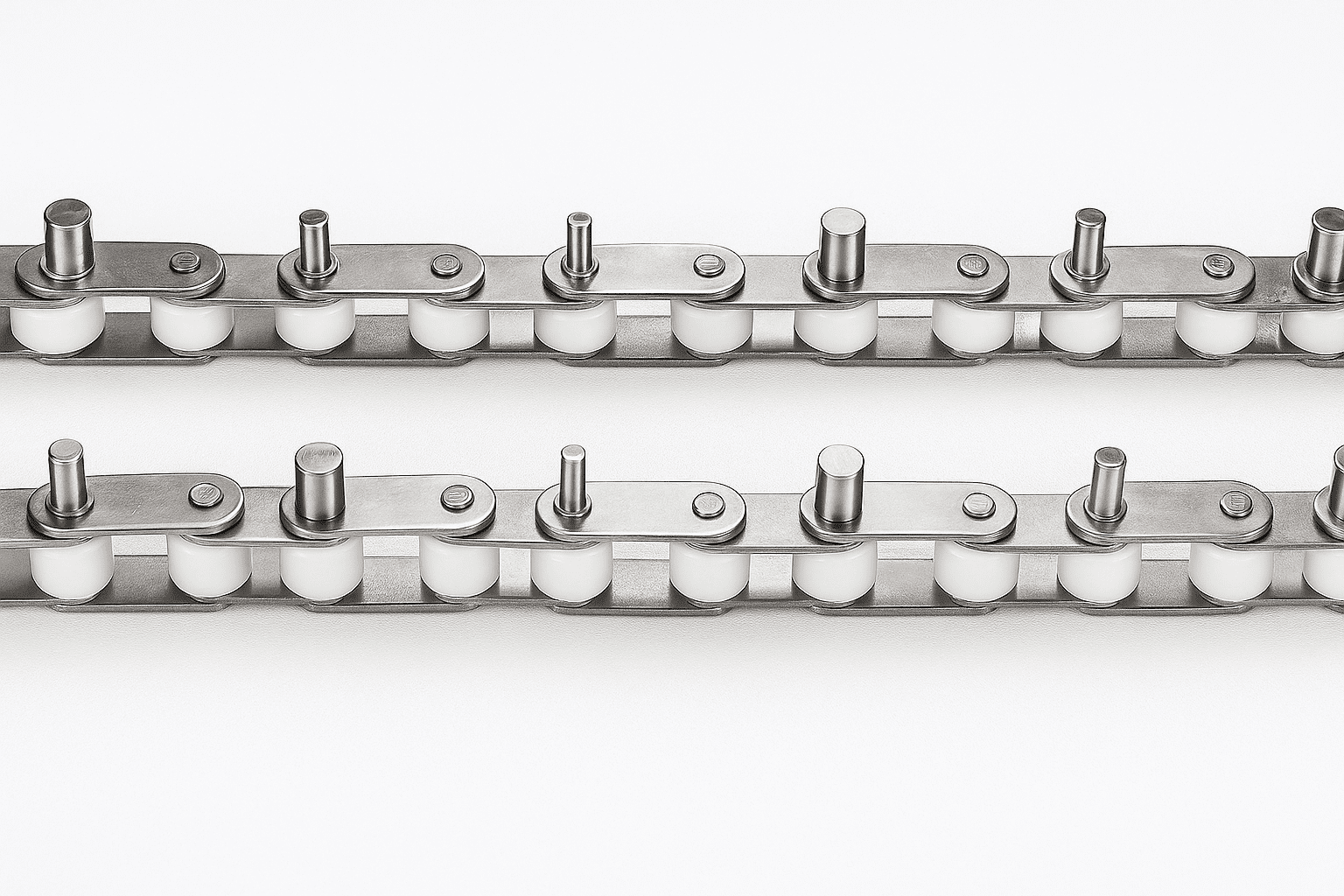

2. The Roller Chain: The Backbone of the System

The roller chain is what connects and drives the buckets. Its strength and durability are critical to the elevator’s reliability.

- Pitch: This is the distance between the centers of two adjacent rollers. The pitch must match the sprockets perfectly. Common pitches vary depending on the machine’s size and capacity.

- Roller Types: The small wheels on the chain that engage with the track and sprockets are a critical wear point. The two most common types are:

- Nylon Rollers: Quieter operation and cost-effective. They are suitable for most standard applications.

- Stainless Steel Rollers: Offer superior durability and wear resistance, making them ideal for heavy-duty applications, high-speed operations, or when conveying abrasive products.

3. The Sprockets: The Driving Force

Sprockets are the toothed wheels that engage with the roller chain to drive the system.

- Drive (Active) Sprocket: Located at the top of the elevator and connected to the motor. This sprocket pulls the entire chain and bucket assembly. Due to the high torque and stress it endures, it is typically made from a highly durable material, most commonly Stainless Steel.

- Driven (Passive) Sprocket: Located at the bottom (boot) of the elevator, it acts as an idler, guiding the chain back up. Since it is not under direct motor torque, it can be made from a high-performance polymer like POM (Polyoxymethylene), which offers excellent wear resistance and quieter operation.

4. The Bearings: The Unsung Heroes

Deep groove ball bearings are used in the shafts of both the drive and driven sprockets. They allow the sprockets to rotate smoothly while supporting the radial and axial loads of the entire system. Quality bearings are essential for reducing friction, noise, and vibration.

When to Replace Components: A Maintenance Checklist

Proactive replacement of wear parts is always cheaper than unplanned downtime. Here are the key signals to watch for:

Buckets

- Visible Cracks or Stress Whitening: Look for fine white lines, especially around the mounting points. This is a sign of material fatigue, and the bucket is at risk of breaking off.

- Deformation: If the bucket has lost its shape or the lip is bent, it can interfere with adjacent buckets or fail to discharge product cleanly.

- Excessive Wear: If the walls of the bucket have become noticeably thinner due to an abrasive product, it’s time for a replacement.

Roller Chain

- Chain Stretch (Elongation): This is the most common failure mode. Over time, the pins and bushings wear, causing the chain’s pitch to increase. A stretch of just 1.5-2% can cause poor sprocket engagement and timing issues. Use a chain wear gauge for accurate measurement.

- Worn or Seized Rollers: If the rollers are visibly worn flat or no longer spin freely, they will cause excessive friction and noise.

- Unusual Noise: A clicking or grinding sound is often the first sign of a worn chain or sprocket.

Sprockets

- Tooth Hooking or Thinning: As the sprocket wears, the teeth will develop a hooked shape or become noticeably thinner. This is a clear sign that the sprocket is worn and will no longer engage properly with the chain.

- Uneven Wear: If you see more wear on one side of the teeth, it indicates a misalignment issue that must be corrected.

Bearings

- Increased Noise or Vibration: A rumbling or grinding sound from the bearing area is a classic sign of internal wear.

- Overheating: If a bearing housing is significantly hotter than the surrounding components, the bearing is likely failing due to lack of lubrication or internal damage.

How to Select the Right Components: A Buyer’s Guide

1. Selecting the Right Bucket

- For Sticky Products (e.g., gummies, fresh-cut fruit): Choose a patterned surface bucket to minimize surface contact and ensure clean discharge.

- For Abrasive Products (e.g., salt, sugar, sand): Choose a more rigid material like ABS or even consider stainless steel buckets for extreme applications.

- For General-Purpose Use (e.g., snacks, grains, pasta): A standard PP bucket with a smooth surface is the most cost-effective and suitable choice.

- Throughput Calculation: Work with your supplier to calculate the required bucket size (e.g., 1.8L vs. 3.8L) based on your product density and target feed rate (kg/hour).

2. Selecting the Right Chain

- For Standard-Duty Applications: A chain with nylon rollers is sufficient and provides quieter operation.

- For Heavy-Duty or High-Speed Applications: A chain with stainless steel rollers is a worthwhile investment for its superior durability and longer lifespan.

- Always replace chains and sprockets together. Installing a new chain on worn sprockets (or vice-versa) will cause accelerated wear on the new component.

3. Selecting the Right Sprockets

- Drive Sprocket: It is highly recommended to use Stainless Steel for the drive sprocket due to the high torque it must handle.

- Driven (Idler) Sprocket: Using a POM sprocket at the bottom is an excellent choice. It is quieter, lighter, and provides a low-friction surface for the chain to glide over.

Maintenance Best Practices

- Regular Cleaning: Keep the buckets, chain, and sprockets free from product residue to prevent buildup and contamination.

- Chain Tensioning: Check chain tension regularly. A chain that is too loose will slap and cause excessive wear, while a chain that is too tight will put stress on the bearings and motor.

- Lubrication (if applicable): While many modern food-grade chains are “lube-free,” some applications may benefit from a food-grade lubricant. Always follow the manufacturer’s recommendations.

- Alignment Checks: Periodically check the alignment of the drive and driven sprockets. Misalignment is a leading cause of premature chain and sprocket wear.

Conclusion: The Foundation of Reliable Elevation

The performance of your bucket elevator is a direct reflection of the quality of its components. By understanding the roles of the buckets, chains, and sprockets, you can make informed decisions about selection and maintenance. Investing in high-quality, application-appropriate components is not a cost; it is an investment in uptime, efficiency, and peace of mind.

If you are looking to replace worn components or select the right parts for a new machine, the experts at Fill-Package are here to help. Explore our full range of bucket elevator components or contact us for a personalized quote.