What Is a Screw Feeder Multihead Weigher?

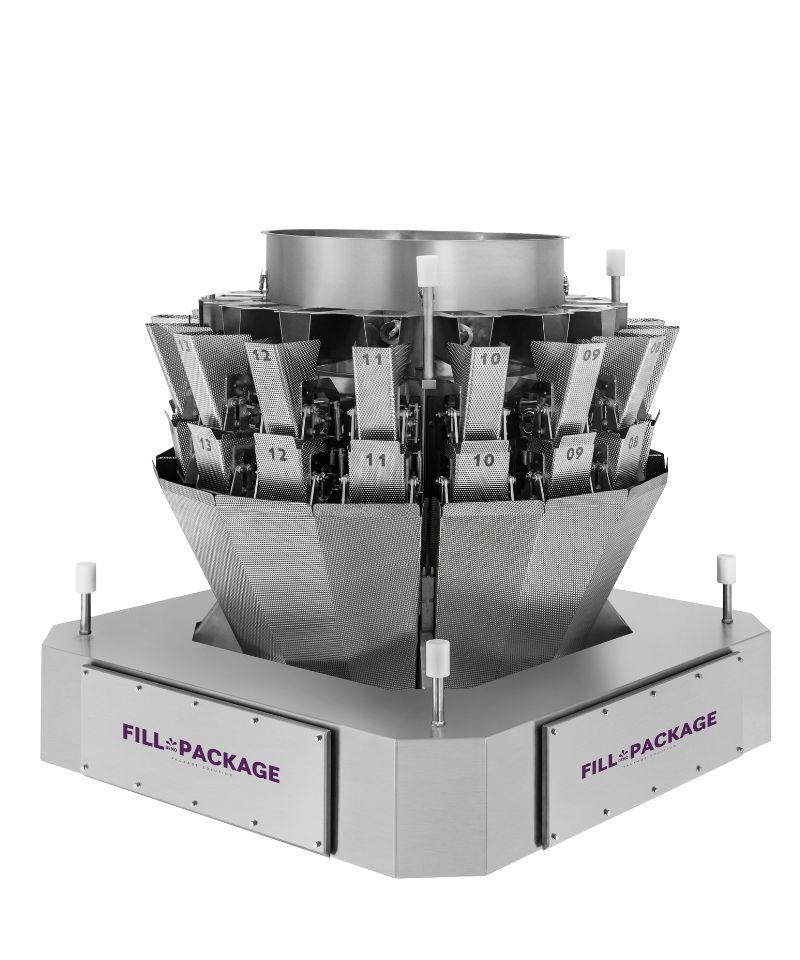

A screw feeder multihead weigher is a type of combination weigher designed for products that cannot be handled efficiently by standard vibration feeding.

Unlike traditional multihead weighers that rely on vibration plates, this system uses controlled screw feeding to deliver products steadily into each weighing hopper.

This makes it ideal for sticky, moist, oily, or non-free-flowing products commonly found in food processing and packaging lines.

Also known as:

combination weigher with screw feeding

computer combination weigher for sticky products

Engineered for the Toughest Materials

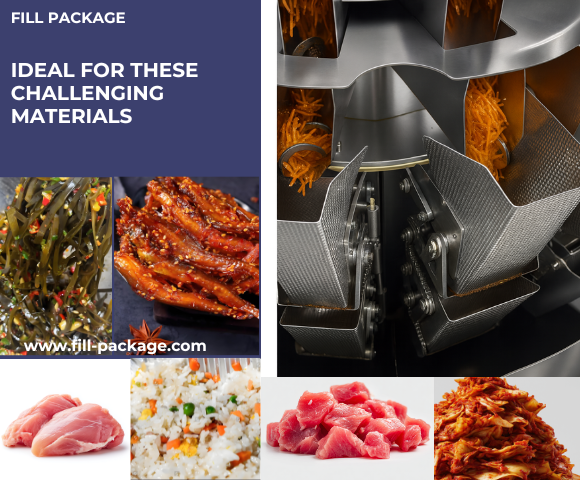

Forced Screw Feeding: Independent high-torque screws actively transport products into hoppers, overcoming surface tension.

Optional Rolling Cup Technology: Upgrade to 180° rotating cups for 100% discharge of extremely sticky items.

IP65 Waterproof Design: Built with high-grade stainless steel to support daily high-pressure washdowns.

Teflon Surface Treatment: Optional anti-stick coatings for sugar-coated or heavily marinated products.

Tool-Free Disassembly: Quickly remove all contact parts for easy cleaning and fast strain changeovers.

- Why Choose Screw Feeding Instead of Vibration Feeding?

- Datasheet

Feeding Method Comparison

| Feeding Type | Suitable Products | Common Limitations |

|---|---|---|

| Vibration Feeding | Free-flowing granules, dry snacks | Unstable with sticky or moist products |

| Screw Feeding | Sticky, oily, irregular products | Designed for controlled, consistent flow |

Screw feeding enables precise control of product movement, thereby reducing product sticking, bridging, and inconsistent weighing typically caused by vibration-based systems.

Multi Head Weigher Specifications

Our combination weighers are built with performance and durability in mind, using high-quality materials and components designed for food-grade applications.

| Technical Parameter | Specification Range |

| Number of Heads | 10 / 14 / 16 / 20 / 24 Heads |

| Hopper Capacity | 0.5L / 1.0L / 1.6L / 2.5L / 3.0L / 5.0L |

| Weighing Range | 10g – 5,000g (Depends on material volume) |

| Weighing Accuracy | ± 0.3g – 1.5g |

| Load Cell Brand | German HBM (Standard High-Precision) |

| Maximum Speed | Up to 120 bags/min (Depending on model) |

| Control Panel | 10.1″ Color Touch Screen with Multi-language support |

Typical Applications-Perfect for Your Production Line

Our screw feeder multihead weighers are widely used for:

Ideal For These Challenging Materials:

Fresh & Marinated Food: Kimchi, seaweed salad, marinated chicken wings, pickled vegetables.

Ready Meals: Cooked pasta, oily fried rice, diced meat in sauce.

Sticky Snacks: Dried fruits, gummy candies, honey-coated nuts.

If your product tends to clump, stick, or resist vibration, screw feeding is often the most reliable solution.

Designed for Stable and Accurate Weighing

The screw feeder design focuses on process stability, not just speed.

Key advantages include:

- Controlled product flow into each weighing hopper

- Reduced product sticking and residue buildup

- Improved weighing consistency for difficult materials

- Suitable for high-mix, variable production environments

This results in more stable weighing performance, especially in applications where vibration feeding struggles.

BLOG: A Guide to Screw-Feeder Weighers: Model Selection, Structural & Application

Easy Integration into Packaging Lines

Our screw feeder multihead weighers are designed to integrate smoothly with:

- Vertical form fill seal (VFFS) machines

- Automated packaging lines

- Conveying and control systems

Whether you are upgrading an existing line or building a new packaging system, the machine can be configured to match your production requirements.

Part of Our Multihead Weigher Product Range

This screw feeder model is part of our complete

Multihead Weigher product range, designed to handle different product characteristics and production needs.

👉 (internal link to MULTIHEAD WEIGHERS)

Why Choose Fill Package?

- Customized solutions based on real product behavior

- Cost-effective manufacturing with stable quality control

- Focus on machine performance, not spare parts dependency

- Clear communication and engineering-oriented support

We work closely with customers to ensure the weighing solution fits your product, not the other way around.

The Ultimate Maintenance Guide for Screw Feeder Multihead Weighers

How to Choose the Right Screw Feeder Weigher for Your Product Type

Related Technical Insights

- Why Vibration Feeding Fails with Sticky Products

- How to Handle Sticky and Difficult-to-Flow Products

- Screw Feeding vs Vibration Feeding

Yes. That’s exactly what this weigher system is built for. We’ll customize the screw size, pitch, and even test your actual material. You’ll receive a video before we build anything.

Yes. Our software stores multiple product profiles. With one touch, your operator can switch between saved settings.

We solve these through a mix of controlled screw feeding, surface treatment (Teflon or dimples), and customized hopper gates like our scraper-type design.

Absolutely. Logo, language, panel screen—we’ll make it look like your own.

Usually 30–45 days. We confirm specs and test your product first—then build.

Products that are sticky, moist, oily, or difficult to flow smoothly typically require screw feeding instead of vibration feeding.

Yes. Screw feeding provides controlled movement, making it suitable for sticky and difficult-to-handle food products.

Vibration feeding relies on product movement through vibration, while screw feeding uses mechanical control to move products steadily.

Yes. Configuration can be adjusted based on product type, production speed, and packaging line requirements.

Get a Screw Feeder Multihead Weigher

Designed for Your Product & Packaging Line