Introduction: Why Precision Parts Define Your Packaging Line

When it comes to food packaging machines, performance doesn’t only rely on large systems like VFFS Machines, Flow Wrappers, or Multihead Weighers. The hidden strength lies in the precision parts—from sprockets and electrical control systems to servo motors—that keep every process accurate and reliable.

At FILL-PACKAGE (www.fill-package.com), we recognize that the right materials and components have a direct impact on efficiency, cost control, and long-term stability. Below, we break down the material choices, pros, and applications of key parts, helping food packaging companies, food production lines, and packaging equipment distributors make confident decisions.

1. Sprockets: Powering Food Conveyors with Reliability

Sprockets are critical in belt conveyors, modular belt conveyors, bucket elevators, cleated conveyors, and flat belt conveyors. They transmit motion, keep belts aligned, and reduce wear.

| Material Type | Advantages | Limitations | Recommended Applications |

|---|---|---|---|

| 304 Stainless Steel | Excellent corrosion resistance, long lifespan, hygienic, high strength | Higher cost compared to other materials | Food conveyor systems, pet food packaging machine lines, environments with water or oil |

| 201 Stainless Steel | Cost-effective, good hardness | Lower corrosion resistance, less suitable for humid or salty environments | Dry product conveyors, low-budget packaging machines |

| Engineering Plastics (POM/Nylon) | Lightweight, lower cost, quiet operation, easy replacement | Lower strength, not suitable for heavy loads or oily surfaces | Rotary packing tables, bowl conveyors, lightweight packaging for chips |

👉 Pro Tip: For automatic packing machines or food packaging machines, always select stainless steel sprockets (304 grade). They withstand moisture, oil, and cleaning chemicals—essential for maintaining hygiene and long-term reliability.

2. Electrical Control Systems: The Brain of Your Line

A robust electrical control system coordinates the entire food packaging line, connecting multihead weighers, sachet counting machines, VFFS machines, and carton sealing machines into one smooth process.

| Material / Component | Key Features | Advantages | Best Use Case |

|---|---|---|---|

| 304 Stainless Steel Cabinet | Corrosion-proof, easy to clean, food-grade compliant | Ensures hygiene and safety | Food production lines, dairy & meat packaging |

| Powder-Coated Steel | Affordable, robust | Less resistant to water and chemicals | Dry goods packaging, low-moisture environments |

| Industrial Wiring & Connectors | Flame-retardant, high-temperature resistance | Improved safety and reduced downtime | High-speed flow wrappers and automatic packaging machines |

👉 Buyer Insight: Always confirm that your supplier provides spare parts and ongoing technical support for control systems. This reduces downtime and ensures your packaging machines stay up to date with the latest standards.

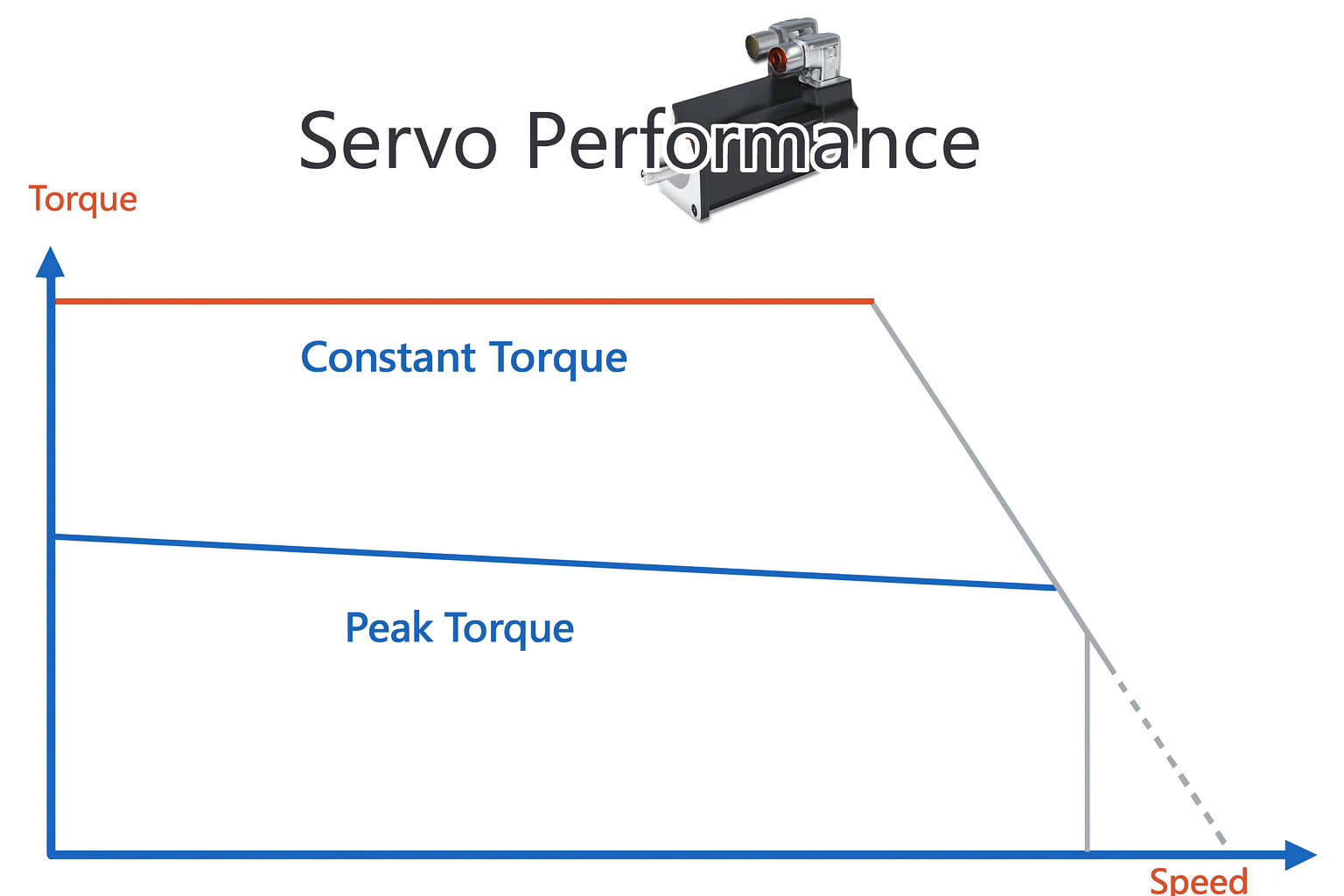

3. Servo Systems: Precision and Energy Efficiency

In modern automation, servo motors and drives ensure accuracy, speed, and energy efficiency. They are essential in multihead weighers, linear weighers, pouch packaging machines, and fastback conveyors.

| Servo Component | Material & Design | Advantages | Applications |

|---|---|---|---|

| Servo Motor Housing (304 SS) | Resistant to corrosion, designed for washdown | Hygienic, long-lasting | Food conveyor, bucket elevator, food packaging machine |

| High-Precision Bearings & Shafts | Hardened steel or alloy | Stable rotation, high load capacity | Rotary packing tables, cleated conveyor belts |

| Digital Servo Drives | Advanced electronics, compact design | Real-time monitoring, energy savings up to 30% | Automatic potato chips packing machine, flow wrappers, VFFS machines |

👉 Case Example: A mid-sized snack factory upgraded its chips packaging machine line with servo-driven bowl conveyors and multihead weighers. The result? 60% faster speed, 40% less energy use, and consistent product quality.

4. Key Takeaways for Choosing Precision Parts

Hygiene first – Always prioritize food-grade stainless steel in environments with moisture, oil, or direct food contact.

Balance cost vs. durability – Use 201 stainless steel or engineering plastics in non-critical or dry sections of your packaging machines.

Smart automation – Integrate servo systems and electrical controls for synchronized, high-speed production.

Future-proofing – Choose parts compatible with food processing equipment, flow wrappers, VFFS machines, and carton sealing machines.

After-sales support – Partner with a reliable supplier like FILL-PACKAGE, who provides spare parts and rapid technical service.

Conclusion: Building Trust Through Material Excellence

The performance of your food packaging machinery depends on the strength of its precision parts. By choosing the right sprockets, electrical control systems, and servo motors, you ensure that every packaging machine—from multihead weighers to automatic potato chips packing machines—delivers consistent, efficient, and hygienic results.

At FILL-PACKAGE, we provide more than just machines. We deliver trustworthy engineering, durable materials, and long-term support that keep your pet food production line and food packaging systems running smoothly.

🌐 Learn more at www.fill-package.com or contact us for a customized precision parts selection guide for your packaging line.