In Z-type bucket elevators used in industries such as food processing, pharmaceuticals, and chemicals, The elevator bucket is a silent hero. It plays a pivotal role in ensuring hygiene, efficiency, and product safety. But in a world flooded with material options—from smooth food-grade polypropylene (PP) to tougher but textured ABS plastic—how do you pick the one that matches your application?

Let’s break it down.

🥊 PP vs. ABS: 5 Critical Differences in Bucket Performance

1. Hygiene & Chemical Resistance

PP (Polypropylene) is the gold standard in food contact applications. It is:

- Resistant to acids and alkalis

- Inert to most solvents

- Mirror-polished (Ra ≤ 0.4μm) for zero residue build-up

- Fully compliant with FDA & GMP regulations

In contrast, ABS may suffer from swelling and cracking when exposed to organic solvents like ketones and esters—often requiring protective coatings like polyurethane to make it usable in harsh environments.

2. Strength vs. Flexibility

- ABS boasts a higher impact strength (up to 30% more than PP) thanks to its three-part copolymer structure (Acrylonitrile + Butadiene + Styrene). Ideal for handling metal parts or abrasive granules.

- PP delivers a lightweight yet tough performance, especially with thin-wall buckets (≤2mm), making it optimal for high-speed chain movement without deformation.

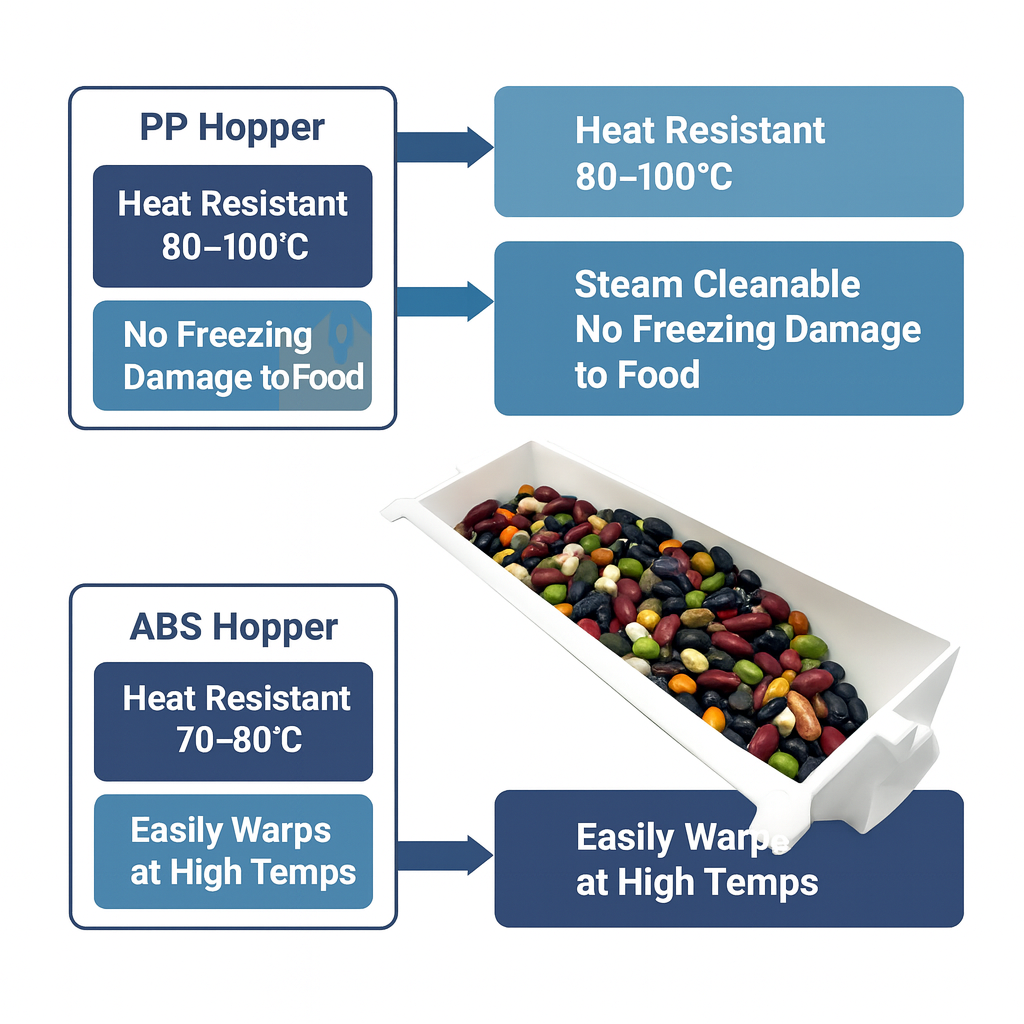

3. Heat Resistance

- PP maintains stability in low and medium temperatures, even down to -40°C.

- ABS tolerates higher operating temperatures (up to 80°C) but becomes brittle in sub-zero conditions—limiting its use in frozen food handling.

4. Cost, Maintenance & Lifecycle

| Property | PP | ABS |

|---|---|---|

| Raw Material Cost | Lower | Higher |

| Weight (per volume) | ~20% lighter | Heavier |

| Static Resistance | Low (less dust attraction) | Needs antistatic coating |

| Cleaning Complexity | Easy (smooth surface) | Requires annealing + ion dust removal |

| Lifecycle in corrosive environments | 2–3x longer | Prone to early wear |

💡 Cost Insight: PP’s lower density (0.91g/cm³ vs ABS’s 1.05g/cm³) means material savings of thousands per ton—especially critical in high-volume facilities.

5. Surface Finish Affects Cleanliness

- PP is clean and smooth post-injection, ensuring <0.5% breakage rate of brittle items like potato chips or candy.

- ABS, on the other hand, may have flow marks or weld lines—potential bacteria traps in food settings.

Hopper Material Selector: Which Is Right for Your Z-Type Bucket Elevator?

| Industry | Recommended Material | Why |

|---|---|---|

| Snacks / Frozen Vegetables | PP | Low-temp resistance, wash-friendly, FDA-compliant |

| Pharmaceutical Capsules | Stainless + PP Liner | Anti-static, easy cleaning, GMP certified |

| Chemicals / Corrosive Powders | Reinforced PP | Acid/alkali resistance, optional tungsten-carbide lining |

| Metal Parts / Hardware | ABS | Shock resistance, scratch-proof when chromed |

Case Insight: A nut-processing plant switched from ABS to PP buckets due to mold risks from textured surfaces. Result? Cleaning time reduced by 40%, customer complaints dropped to zero.

Interactive Q&A: What’s Your Bucket Pain Point?

Cold Storage: You’re conveying frozen strawberries at -30°C—do you choose PP or ABS? Why?

Sticky Materials: For maltose or sugary blends, would you prioritize a self-cleaning slope or a wear-resistant coating?

Large Buckets (e.g. 3.8L): Do you go for extra rib reinforcements or reduce operating speed to minimize stress on Z-bends?

TCO Puzzle: ABS costs more but lasts longer. PP is cheap but may need replacement. How do you calculate total cost of ownership? Share your formula!

Final Thoughts: There’s No “Best,” Only “Best-Fit”

In the world of Z-type bucket elevators, the bucket is both a feat of material science and a calculated compromise.

PP leads in hygiene, weight reduction, and corrosion resistance—ideal for food and pharma.

ABS defends its place in heavy-duty applications where impact resistance and surface durability are key.

Need Help Choosing the Right Hopper?

Comment below with your industry and material type, and we’ll send you a custom selection guide.