Feeding and Conveying Systems for Packaging Lines

Feeding and conveying systems are used to deliver, orient, or control product flow

before weighing and packaging processes.

These systems differ from belt conveyors in both structure and working principle.

The Heartbeat of Your Packaging Line: Mastering Material Flow

Our Feeding & Incline Conveying Solutions (3)

We offer four primary categories of feeding and incline systems, each designed for specific product characteristics and application needs. Explore our solutions below to find the perfect fit for your line.

Flexible Screw Conveyors: The Versatile Workhorse for Powders & Granules

Principle of Operation

Key Benefits

- Dust-Tight Operation: The fully enclosed system prevents product leakage and airborne dust, ensuring a clean, safe, and hygienic plant environment.

- Flexible Routing: Can be maneuvered in any direction, offering unparalleled layout versatility and saving valuable floor space.

- Low Maintenance: With only one moving part (the screw), these systems are exceptionally reliable and require minimal upkeep.

- Gentle Handling: The screw’s design ensures smooth material flow with minimal friction, protecting product integrity.

Ideal Applications

- Food Powders: Flour, sugar, spices, milk powder, coffee grounds, cocoa.

- Chemicals: Pigments, resins, detergents, and other fine chemical powders.

- Plastics: PVC powders, plastic pellets, and regrind.

- Agriculture: Seeds, grains, and animal feed.

Technical Specifications

Parameter | Specification Range |

Tube Diameters | 2.5″ (63mm) to 8″ (200mm) |

Max Throughput | Up to 29,500 lbs/hr (13,400 kg/hr) |

Max Length | Up to 40 ft (12m) per conveyor |

Max Incline Angle | 90 degrees (Vertical) |

Tube Material | UHMWPE (Food Grade), Abrasion-Resistant Polymer |

Screw Types | Round, Flat, Beveled, Knife-Edge |

Construction | 304/316 Stainless Steel Contact Parts |

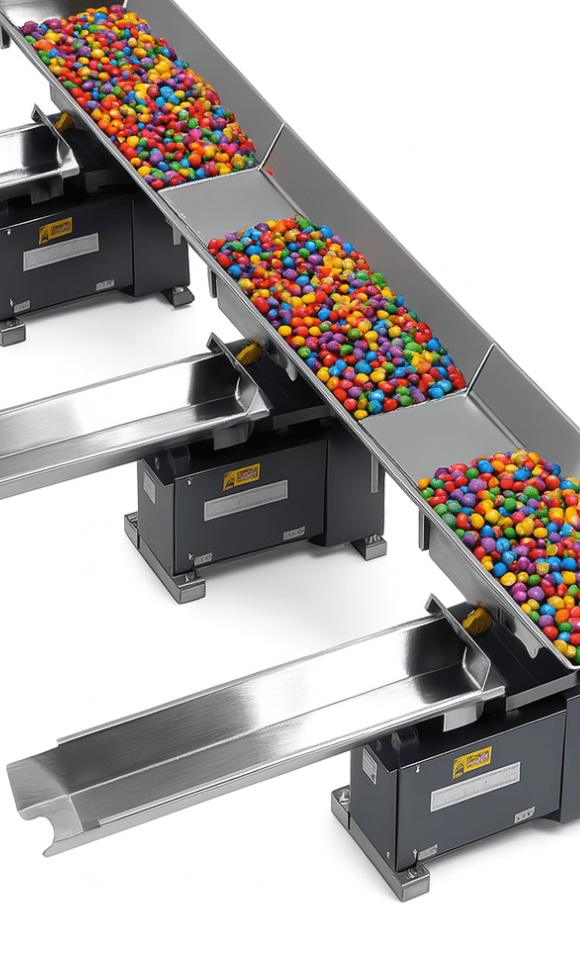

Vibratory & Fastback Conveyors: The Gold Standard for Fragile & Sticky Products

Principle of Operation

Key Benefits

- Zero Breakage: Proven to reduce product breakage by up to 60% compared to other conveying methods, preserving the quality of high-value, fragile items.

- No Segregation: Blended products (like trail mix or seasoned snacks) remain perfectly mixed without separating, ensuring consistency in every package.

- Easy to Clean: The smooth, open pan has no crevices, hinges, or hidden areas, allowing for rapid and thorough sanitation, reducing downtime between runs.

- No Sticking: The horizontal motion prevents sticky products (like cheese or gummies) from adhering to the pan surface.

Ideal Applications

- Fragile Snacks: Potato chips, pretzels, crackers, tortilla chips, and extruded snacks.

- Coated Products: Seasoned nuts, confectionery, chocolate-coated items, and glazed foods.

- Sticky & Wet Products: Shredded cheese, fresh-cut produce, gummy candies, and marinated meats.

- Blended Products: Trail mixes, cereals, and multi-component meal kits.

Technical Specifications

Parameter | Specification Range |

Pan Widths | 8″ (200mm) to 48″ (1220mm) |

Throughput | Up to 50,000 lbs/hr (22,700 kg/hr) |

Pan Materials | 304/316 Stainless Steel, Dimpled, Polished, Coated |

Drive System | Electromagnetic, Mechanical |

Control | Variable speed control, integrated start/stop with weighers |

Mounting | Floor-mounted, Ceiling-hung |

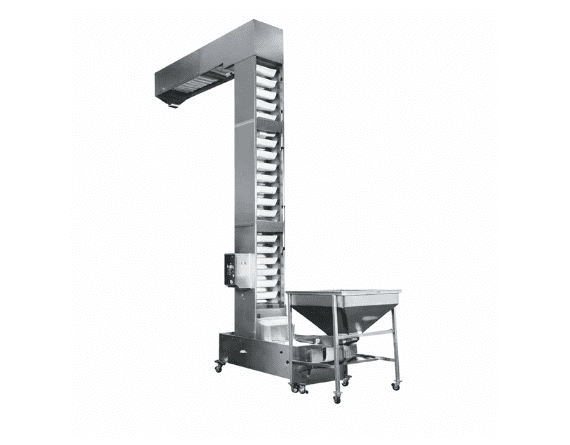

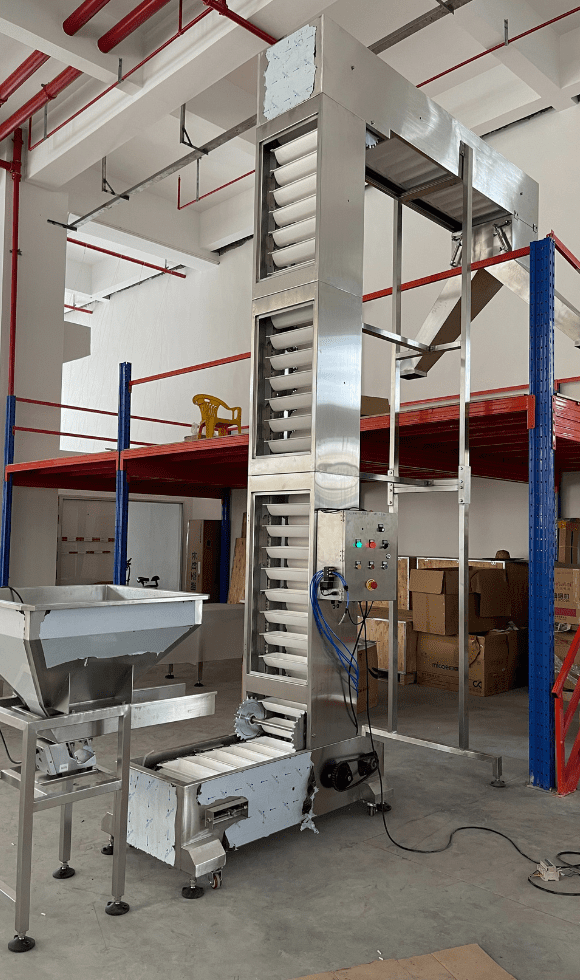

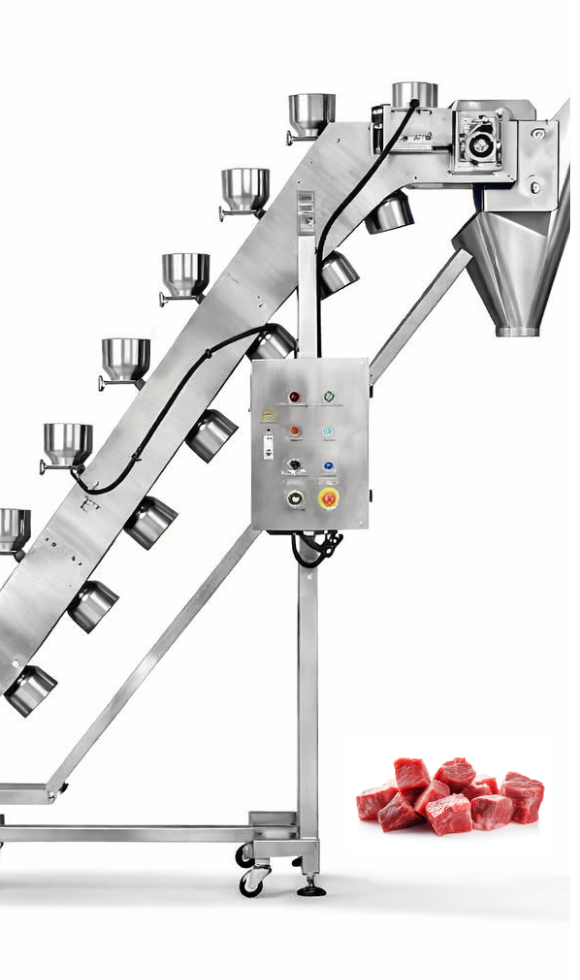

Bucket Elevators & Incline Conveyors: The Ultimate Solution for Vertical Lift

Principle of Operation

- Bucket Elevators: A series of interlocking buckets are attached to a chain or belt. Material is fed into the buckets at the base, lifted vertically, and then gently discharged at the top as the buckets tip.

- Incline Belt Conveyors: A standard belt conveyor is fitted with cleats or sidewalls and positioned at an angle. The cleats prevent product from rolling back, while sidewalls contain the material.

Key Benefits

- High Vertical Lift: Can elevate products to significant heights within a very small footprint, saving valuable floor space.

- Gentle Handling (Bucket Elevators): Product rests stationary within the buckets during transport, eliminating impact and degradation.

- Zero Spillage: The interlocking bucket design or corrugated sidewalls ensure that all product is contained during elevation.

- High Capacity: Capable of moving large volumes of product efficiently.

Ideal Applications

- Feeding Multihead Weighers: The most common application, providing a consistent, gentle feed to weighers mounted on a mezzanine.

- Bulk Material Handling: Elevating grains, seeds, coffee beans, pet food, and other bulk solids.

- Fragile Items (Bucket Elevators): Nuts, hard candies, frozen foods, and other items that could be damaged on a standard incline belt.

- Space-Constrained Layouts: Perfect for facilities where floor space is at a premium.

Technical Specifications

Parameter | Bucket Elevator | Incline Belt Conveyor |

Max Discharge Height | Up to 100 ft (30m) | Up to 20 ft (6m) |

Capacity | Up to 2,000 ft³/hr | Up to 1,500 ft³/hr |

Bucket Material | Polypropylene, Metal-Detectable Plastic | N/A |

Belt Material | N/A | PVC, PU, Rubber |

Cleat/Sidewall Height | N/A | 1″ (25mm) to 6″ (150mm) |

Construction | Stainless Steel, Painted Mild Steel | Stainless Steel, Aluminum |

Bowl & Linear Feeders: Precision Orientation for Small Components

Principle of Operation

- Bowl Feeders: A vibratory drive causes parts in a conical bowl to move up a spiral track. Custom-designed tooling along the track orients the parts into the desired position, rejecting any that are misaligned.

- Linear Feeders: A straight, vibratory track that transports already-oriented parts from the bowl feeder to the downstream equipment, acting as a buffer and ensuring a smooth transition.

Key Benefits

- High-Speed Orientation: Automatically orients thousands of parts per hour, dramatically reducing manual labor and increasing throughput.

- Accurate Metering: Provides a reliable, controllable, and precise flow rate, preventing jams and ensuring accuracy in counting and assembly.

- Custom Tooling: Each bowl is custom-tooled for a specific part, guaranteeing reliable orientation and performance.

- Compact Footprint: Delivers a high-density feeding solution within a minimal space.

Ideal Applications

- Hardware & Kitting: Screws, nuts, bolts, washers, and other small components for automated kitting.

- Pharmaceuticals: Pills, tablets, and capsules for bottling and blister packing lines.

- Caps & Closures: Feeding bottle caps, lids, and spray triggers to capping machines.

- Electronics: Orienting small electronic components for automated assembly.

Technical Specifications

Parameter | Specification Range |

Bowl Diameter | 6″ (150mm) to 48″ (1220mm) |

Track Width | Custom-tooled for part dimensions |

Feed Rate | Up to 1,000 parts per minute (depending on part) |

Bowl Material | 304/316 Stainless Steel, Coated Surfaces |

Control | Variable vibration frequency controller |

Noise Level | Acoustic enclosures available to reduce noise |

How to Select the Right Feeding & Incline System

Choosing the optimal system is a strategic decision. Use this guide to identify the best technology for your product and process.

If Your Priority Is… | And Your Product Is… | The Best Solution Is… |

Dust Control & Flexibility | A powder, granule, or bulk solid (e.g., flour, coffee) | Flexible Screw Conveyor |

Gentle Handling / No Breakage | Fragile, coated, or seasoned (e.g., potato chips, nuts) | Vibratory / Fastback Conveyor |

Preventing Sticking | Sticky, oily, or wet (e.g., shredded cheese, gummies) | Vibratory / Fastback Conveyor |

Vertical Lift in Small Footprint | Any bulk material, especially fragile items | Bucket Elevator |

Simple Elevation | Durable, free-flowing products (e.g., grains, pellets) | Incline Belt Conveyor |

Part Orientation & Sorting | Small, uniform components (e.g., screws, caps, pills) | Bowl & Linear Feeder |

Related Product

Feeding systems are typically installed before weighing or packaging equipment,

while belt conveyors are mainly used for product transfer within packaging lines.

Blogs

1.Why Feeding Systems Matter in Automated Packaging Lines

2.How to Choose the Right Feeding System for Your Packaging Line

3.Feeding Systems vs Conveyor Systems: Understanding the Difference

A standard vibratory conveyor uses an angled vibration to bounce product forward, which can cause breakage and coating loss. A Fastback uses a patented slow-forward, quick-back horizontal motion that allows the product to glide without leaving the pan, making it significantly gentler.

While gentle, flexible screw conveyors are generally not recommended for highly friable products like potato chips or delicate crackers. The tumbling action inside the tube can cause some breakage. They are best for robust powders and granules.

Our bucket elevators can be configured for discharge heights of up to 100 feet (30 meters), making them suitable for almost any mezzanine or multi-level facility layout.

It is highly recommended. The bowl feeder orients the parts, but the linear feeder acts as a crucial buffer. It accumulates a ready supply of oriented parts, ensuring a consistent, on-demand flow to the downstream machine, even if the bowl feeder momentarily stops.

All our systems intended for food applications are designed according to sanitary principles. This includes using 304/316 stainless steel, continuously welded seams, polished surfaces, tool-less disassembly for cleaning, and eliminating crevices where bacteria could harbor.

Generally, no. Bowl feeders are custom-tooled for the specific size, shape, and weight of a single part. Using a different part will result in poor or no orientation. For multiple parts, you would typically need separate, interchangeable bowls.

Fastback conveyors are known for their low maintenance. The drive units are robust and long-lasting. Routine maintenance typically involves periodic inspection of the drive and ensuring the pan surface is clean and undamaged. There are no belts, chains, or sprockets to maintain in the product zone.

Choose a Bucket Elevator if your product is very fragile, if you need to lift to a great height, or if floor space is extremely limited. Choose an Incline Belt Conveyor for a more cost-effective solution if your product is durable and the incline angle is less than 45-60 degrees.