Elevator Bucket

Product Overview

Our Z-Type bucket elevator buckets are engineered for reliable vertical and horizontal conveying in complex material handling systems. Manufactured from premium polypropylene (PP), ABS, and polyethylene (PE), these elevator buckets deliver excellent chemical resistance, mechanical strength, and wear durability—making them ideal bucket elevator parts for industries requiring efficient and gentle material transport.

Designed specifically as a bucket for bucket elevator, these plastic buckets ensure smooth flow of granular and powder materials through Z-type conveyors with minimal product degradation and reduced maintenance needs.

Buckets Key Features

- Material Options: Choose from robust PP for chemical resistance and toughness, ABS for enhanced impact strength and surface finish, or PE for excellent low-temperature flexibility and cost efficiency.

- Standard Capacities: many common size 2.0L and 4.0L sizes, these bucket elevator bucket types cater to varying throughput requirements while maintaining system compatibility.

- Surface Finish Options: Select between smooth or textured surfaces to optimize material flow, prevent bridging, and facilitate easy cleaning.

- Lightweight & Durable: Plastic construction reduces conveyor load, lowers energy consumption, and extends component life.

- Compatibility: Designed to seamlessly integrate with a wide range of bucket elevator parts, facilitating easy replacements and system upgrades.

Elevator Buckets Applications

Our plastic bucket elevator buckets are widely used across multiple industries, including:

- Food processing (grains, snacks, frozen foods)

- Pharmaceuticals (tablets, capsules, powders)

- Chemicals (granular chemicals, additives)

- Agriculture (seeds, fertilizers, feed)

- Packaging automation systems

These buckets offer gentle material handling, which is critical for maintaining product integrity in sensitive applications, making them the ideal choice for a bucket elevator solution.

Why Choose Our Plastic Elevator Buckets?

- Proven Durability: Manufactured under strict quality controls using certified materials for consistent performance.

- Energy Efficient: Lightweight buckets reduce drive load and lower power consumption.

- Customizable Solutions: Tailored designs available to meet unique operational requirements.

- Comprehensive Support: Expert engineering assistance from selection to installation and maintenance.

System Compatibility & Installation

Our bucket elevator buckets are designed to be fully compatible with most standard Z-type bucket elevator systems in the market. Whether you’re upgrading existing equipment or building a new line, our buckets can be easily installed without modifications.

Key Compatibility Features:

- Compatible with standard elevator chains and sprockets (ISO & DIN standards)

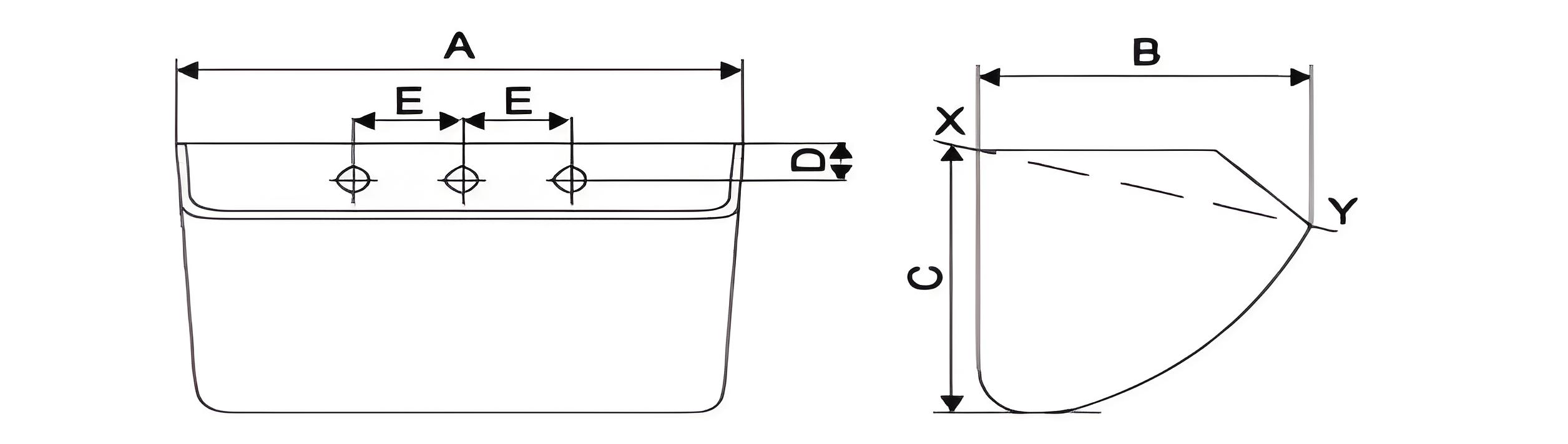

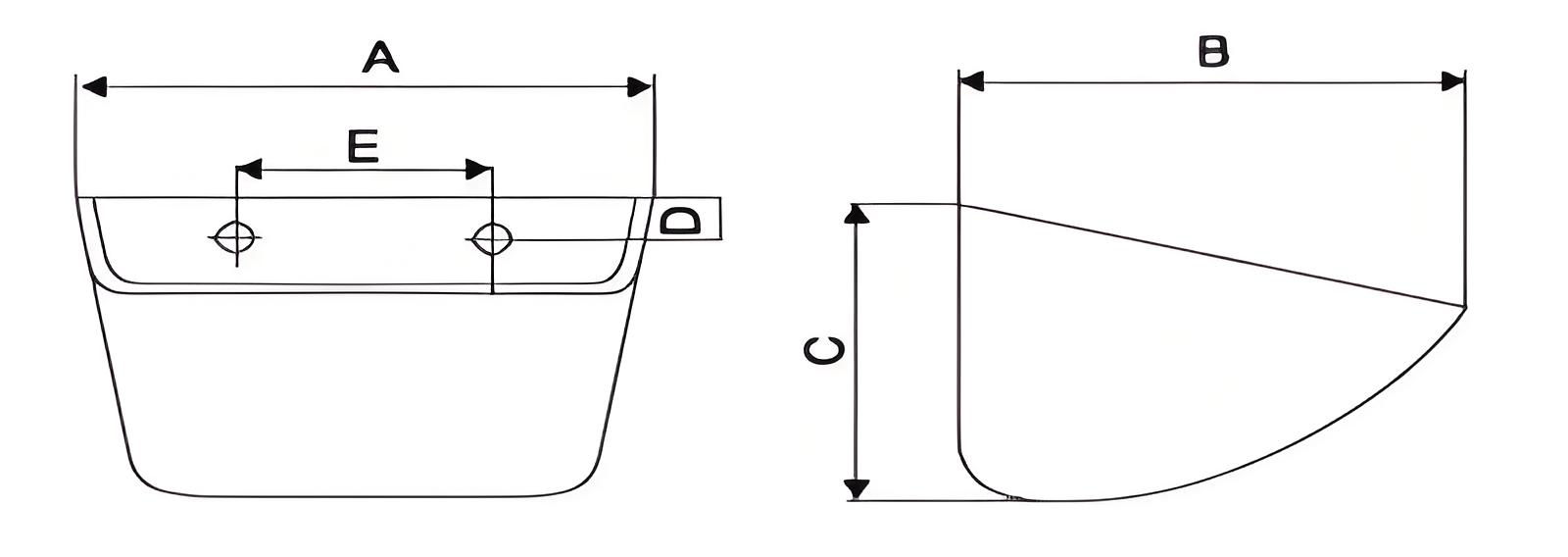

- Multiple mounting hole options available for flexible fit

- Compatible with common elevator brands such as: Yamato, Nerak, Flexicon, Gough, etc.

- Available in left/right-hand and symmetrical configurations

Material Safety & Certifications

We understand that industries like food and pharmaceuticals demand the highest levels of safety and compliance. That’s why our bucket for bucket elevator products are made using certified raw materials that meet international standards.

Available Certifications:

✅ FDA Food Contact Approved (PP material)

✅ EU 10/2011 Compliance

✅ BPA-Free & Non-toxic

✅ REACH / RoHS Environmental Compliance

✅ HACCP-Compatible Design

Warranty & After-Sales Support

We stand by the quality of every bucket elevator part we produce.

Warranty Policy:

- 12-Month Standard Product Warranty

- Free replacement for manufacturing defects

- Lifetime technical support for installation and usage issues

Need help choosing the right elevator bucket for your system? Our engineers are here to assis

Customization Capabilities

We understand that one size doesn’t fit all. That’s why we offer full OEM/ODM services tailored to your needs.

Custom Options Include:

- Special Sizes or Shapes

- Custom Colors

- Logo Printing & Serial Numbering

- Custom Material Formulations (e.g., anti-static, UV-resistant)

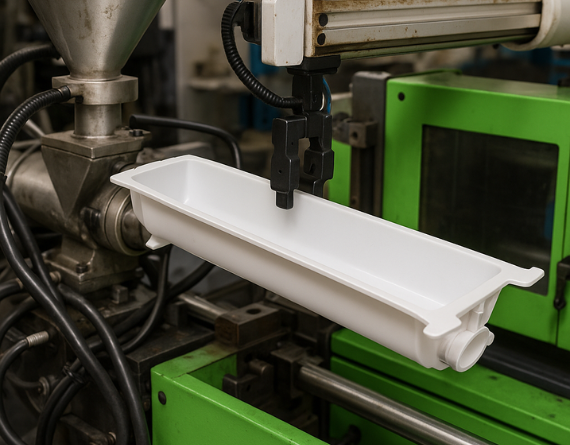

Mold Design for High-Volume Projects

Minimum Order Quantity (MOQ) for customization: 1,000 pcs.

lightweight high-strength plastic elevator buckets

- Product Highlight: Lightweight High-Strength Plastic Elevator Buckets

- Available Materials & Physical Properties

- Ideal Applications

- Summary of Advantages

Our lightweight high-strength plastic elevator buckets are engineered to outperform traditional steel buckets across critical performance metrics. As a modern solution in vertical conveying, these advanced bucket elevator bucket types are optimized for reliability, energy savings, and safety in demanding environments.

Key Performance Features:

- Superior Mechanical Strength

Constructed with reinforced thermoplastics, these buckets for bucket elevator systems offer high tensile strength, excellent abrasion resistance, and long-lasting durability—significantly exceeding the service life of conventional steel buckets. - Lightweight Design

With a much lower self-weight compared to metal buckets, these plastic bucket elevator parts reduce the load on bucket elevator belts, extend the belt’s service life, and lower the system’s energy consumption. - Excellent Flexibility, Minimal Material Damage

Due to their elasticity, plastic elevator buckets drastically reduce material breakage during conveying. Damage rate of fragile bulk materials can be as low as 1%, making them ideal for handling delicate goods such as grains, seeds, or tablets. - No Spark, No Explosion Hazard

These buckets do not produce sparks under friction, significantly lowering the risk of dust explosions in environments with combustible powders. Their anti-static properties also reduce the chance of electrostatic discharge. - Clean Discharge and Wide Temperature Range

Designed with optimal geometry and flow properties, the buckets provide clean and complete discharge. They operate reliably across a broad temperature range, making them suitable for both cold storage and moderately heated environments.

Our plastic elevator buckets are available in two high-performance materials: Modified High-Density Polyethylene (HDPE) and Nylon (PA6). Each offers unique advantages depending on your conveying needs.

🔹 Modified High-Density Polyethylene (HDPE)

| Property | Value |

|---|---|

| Density | 0.935 – 0.960 g/cm³ |

| Tensile Strength | 2900 N/cm |

| Elongation at Break | 300% |

| Working Temperature Range | -50°C to +80°C |

| Melting Point | 136°C |

| Vicat Softening Point | 134°C |

| Brittleness Temperature | ≤ -70°C |

| Thermal Expansion Coefficient | 1.5 × 10⁻⁴ /°C |

| Heat Distortion Temperature | 85°C |

| Wear Rate (Average) | ≤ 1.32 mm³ |

| Friction Coefficient | 0.08 – 0.12 |

| Volume Resistivity | ≤ 7 × 10¹⁴ Ω·cm |

| Anti-static / No spark under impact | Yes |

🔹 Nylon (Polyamide PA6)

| Property | Value |

|---|---|

| Density | 1.14 g/cm³ |

| Tensile Strength | 82.7 MPa |

| Elongation at Break | 2300% |

| Working Temperature Range | -40°C to +105°C |

| Melting Point | 255°C |

| Brittleness Temperature | -80°C |

| Thermal Expansion Coefficient | 7 × 10⁻⁵ /°C |

| Heat Distortion Temperature | 255°C (at 0.5 MPa) |

| Volume Resistivity | ≤ 7 × 10¹⁴ Ω·cm |

| Anti-static / Spark-proof | Yes |

These enhanced plastic bucket elevator buckets are particularly suitable for:

Food industry: grains, rice, sugar, starches, puffed snacks

Pharmaceuticals: tablets, granules, capsules

Agriculture: animal feed, fertilizer, seeds

Chemical industry: powders, catalysts, abrasives

Cold-chain logistics: frozen vegetables, chilled goods

With the right material selection, our buckets for bucket elevator systems can handle extreme environments—ranging from sub-zero cold rooms to mid-range heat conditions—while offering unmatched performance, low friction, and safe operation.

| Feature | Benefit |

|---|---|

| High mechanical strength | Long service life, reduced replacements |

| Lightweight | Low energy consumption, extended belt life |

| Anti-spark design | Explosion-proof for combustible dust applications |

| Smooth discharge | No material retention, clean operation |

| Anti-static properties | Reduced electrostatic hazards |

| Temperature resistance | From -50°C to 105°C (material-dependent) |

| Flexibility | Less damage to transported materials |

Related Product

An elevator bucket is a container attached to a belt or chain in a bucket elevator system. It scoops up bulk materials at a lower point, carries them vertically, and discharges them at an upper level. It is one of the most essential bucket elevator parts, used for transporting powders, granules, and small-sized solids in a controlled manner.

We offer bucket for bucket elevator systems in three high-performance plastics:

- Polypropylene (PP) – Excellent chemical resistance, food-grade, suitable for most materials

- ABS – High impact resistance, good surface finish, ideal for abrasive or heavy-duty applications

- Polyethylene (PE) – Flexible, cost-effective, suitable for low-temperature or non-abrasive materials

Custom materials like Nylon (PA6) or antistatic/UV-resistant compounds are also available upon request.

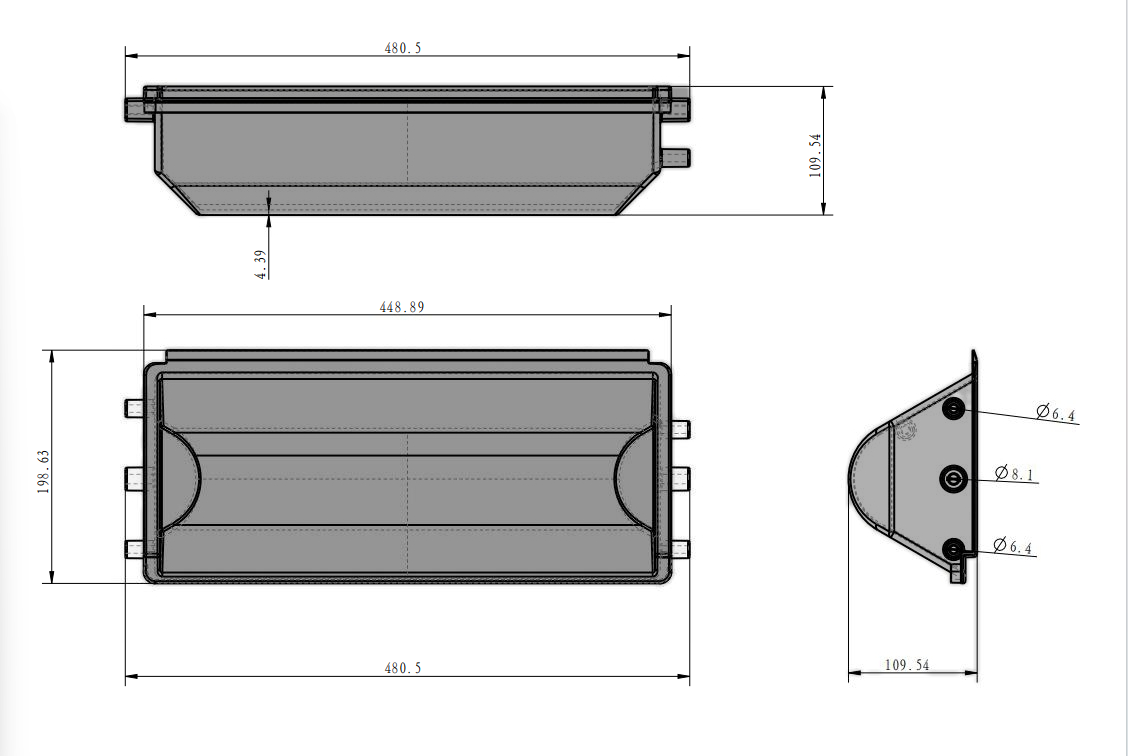

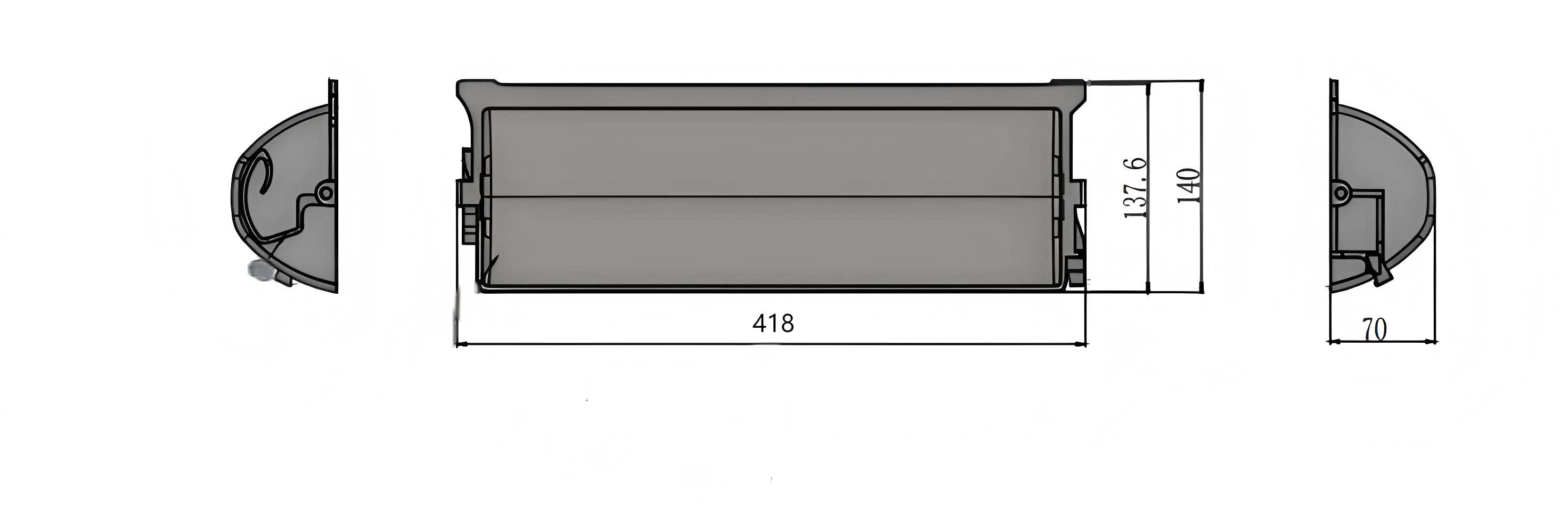

We offer a wide range of elevator bucket sizes and capacities to accommodate different material types, throughput requirements, and elevator configurations. Whether you need small, precise dosing or large-volume bulk handling, we have the right bucket elevator bucket types for your system.

🔹 Standard sizes include:

- 1.0L – For light-duty applications or compact systems

- 1.5L

- 2.0L (effective ~1.8L) – Popular for food, pharma, and chemical use

- 2.5L

- 3.0L

- 4.0L (effective ~3.8L) – Ideal for high-volume applications

- 5.0L

- Custom sizes available upon request

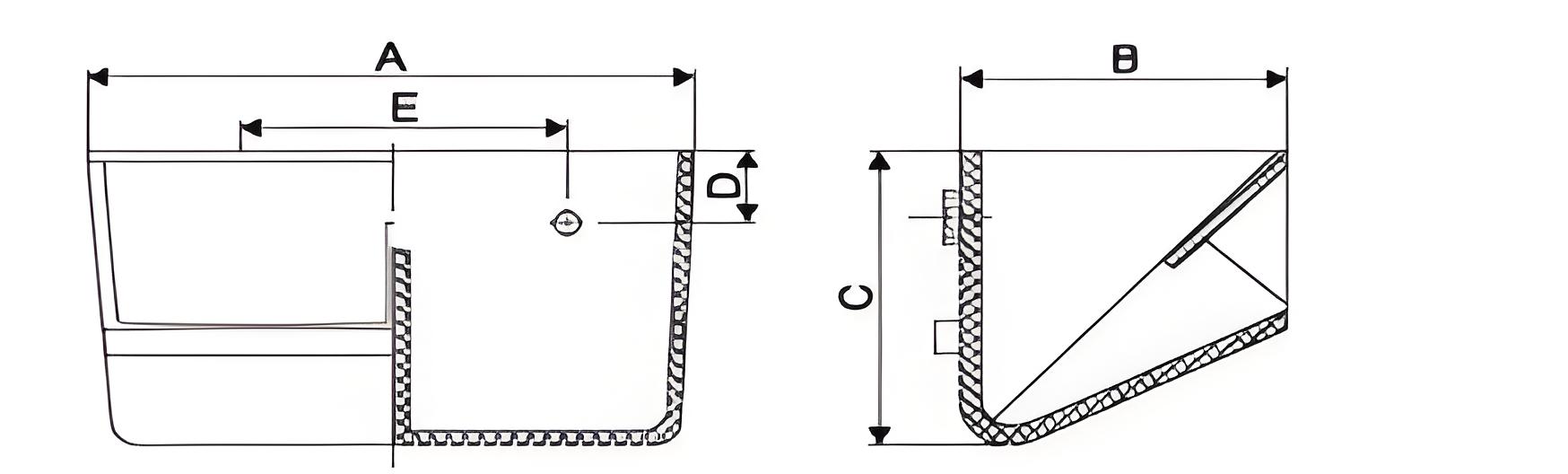

All sizes can be customized in terms of dimensions (length, width, depth), mounting hole position, and geometry to fit your specific bucket for bucket elevator system.

Choosing the correct bucket for bucket elevator use depends on:

- Material to be conveyed (abrasive, sticky, fragile, high-temp, etc.)

- Required capacity and throughput

- Temperature and humidity conditions

- Belt or chain configuration

- Hygiene and certification requirements (e.g., FDA, EU 10/2011)

Our technical team can help recommend the most suitable bucket elevator bucket types based on your specific use case.

Plastic elevator buckets offer several benefits compared to metal options:

- Corrosion and chemical resistance

- Lighter weight reduces energy consumption

- No sparks during operation — safer in explosive environments

- Lower noise and less wear on the belt or chain

- Smoother internal surface ensures cleaner discharge

Yes. Our bucket elevator buckets made from PP and PE are FDA-compliant and meet EU 10/2011 food contact standards. They are BPA-free and suitable for use in food processing, pharmaceuticals, and hygiene-sensitive industries.

Certification documents and third-party testing reports are available upon request.

The service life depends on the working conditions and the material being conveyed. However, our high-quality plastic bucket elevator parts often last 2–5 years, sometimes longer, under standard operating conditions. Proper maintenance and material compatibility also play a key role in durability.

Absolutely. We support OEM/ODM customization, including:

Special sizes or shapes

Custom colors or branding (e.g., logo embossing)

Special materials (anti-static, UV-resistant, high-temperature)

Mold design for large-volume applications

Minimum order quantity (MOQ) for customization typically starts at 1,000 pcs.

Yes. Our plastic bucket elevator buckets are designed to operate safely in potentially explosive environments. They do not produce sparks under friction, and many options offer anti-static properties to reduce the risk of electrostatic discharge, making them ideal for dust-prone operations such as flour mills, chemical plants, and grain elevators.

Most likely, yes. Our buckets are designed to be compatible with standard bucket elevator parts and can integrate with most major Z-type or vertical elevator systems. If needed, we offer:

- CAD drawings

- Mounting hole customization

- Chain pitch alignment

- Retro-fit design support

Contact our engineering team with your current setup, and we’ll confirm compatibility or suggest a fit.

- In-stock standard models: Ship within 2–5 business days

- Custom orders: Typically ship within 10–20 working days depending on complexity

- New mold development: 25–30 days, including design confirmation

We offer global shipping, bulk discounts, and partial delivery plans upon request.

We provide full pre-sales and post-sales technical support, including:

Bucket selection consulting

Custom design development

Installation guidance

Maintenance best practices

Failure analysis and troubleshooting

Our goal is to ensure your bucket elevator bucket performs reliably throughout its service life.