The Multi-head weigher, also call combination scale. is one of the most importance machine in automated packaging systems. It calculates based on the combination principle, and selects the combination that is closest to the target weight from many combinations when every time the materials are discharged.

Choose the combination closest to the target weight during many combinations

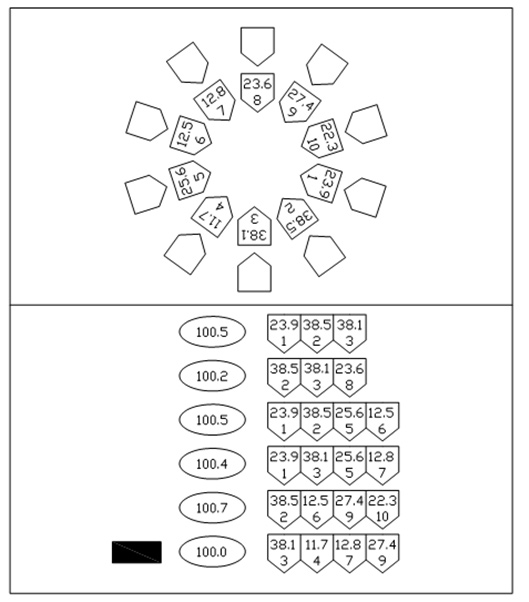

Generally, A multi-head weigher have more than 10 heads, each head is individual weighing unit with load cell. It can independently weigh the material stored in its hopper. When the multi-head weigher finish weighing and empties the weighing hopper, the feeding hopper is opened to discharge materials into the weighing hopper and weigh ,then signal will be sent to motherboard. The CPU on the motherboard reads and records the weight of each weighing hopper, and then calculates, analyzes, and selects the combination weighing hopper closest to the target weight. For example :

The target weight of a 10-head combination scale is 100g, with an upper limited of 1g and a lower limited of 0g. The following image shows a certain combination situation.”

It is not difficult to find that the more the number of heads of the combination scale heads, the more the number of combinations. At the same time, when the number of selected combination hoppers is half of the number of weigher, the number of participating hoppers is higher and the accuracy is the best. The following table is a reference comparison of the number of possible combinations of 10-head and 14-head combination scales when different numbers of hoppers are selected.”

| Number of selected hoppers | 10 Head Multihead Weigher | 14Head Multihead Weigher |

| 1 | 10 | 14 |

| 2 | 45 | 91 |

| 3 | 120 | 364 |

| 4 | 210 | 1001 |

| 5 | 252 | 2002 |

| 6 | 210 | 3003 |

| 7 | 120 | 3432 |

| 8 | 45 | 3003 |

| 9 | 10 | 2002 |

Continuously optimizing within a combination, gradually approaching the target weight.

Generally speaking , combination scale needs to be combined several times to gradually reduce the tolerance and finally achieve the required accuracy.combination scales usually use feedback adjustment to continuously adjust the weight of each scale head, gradually approach the target weight. During the combination process, the combination unit calculates the current error and issues an adjustment signal. These adjustment signals are transmitted to the scale head unit to adjust the weight of each scale head. Through iterative adjustment, the multi-head combination scale can gradually approach the target weight until the error is controlled within an acceptable range.

Factors Affecting Combination

The adjustment time and number of a multi-head combination scale may be affected by various factors such as material characteristics, flow rate, target accuracy, and the design of the combination scale. In practical applications, it is necessary to design and adjust according to specific situations.”