Introduction

In the world of packaging automation, the Vertical Form Fill Seal (VFFS) machine is one of the most widely used and efficient pieces of equipment. From potato chips and coffee powder to laundry detergent, countless bagged products in daily life owe their neat, consistent packaging to these machines.

A VFFS machine has the remarkable ability to take a flat roll of packaging film and transform it into finished bags—complete with product filling and sealing—in one continuous process. In this guide, we’ll break down the working principle and core components of VFFS machines, providing valuable insights for distributors, agents, and packaging machinery dealers.

The Automated Workflow of a VFFS Machine

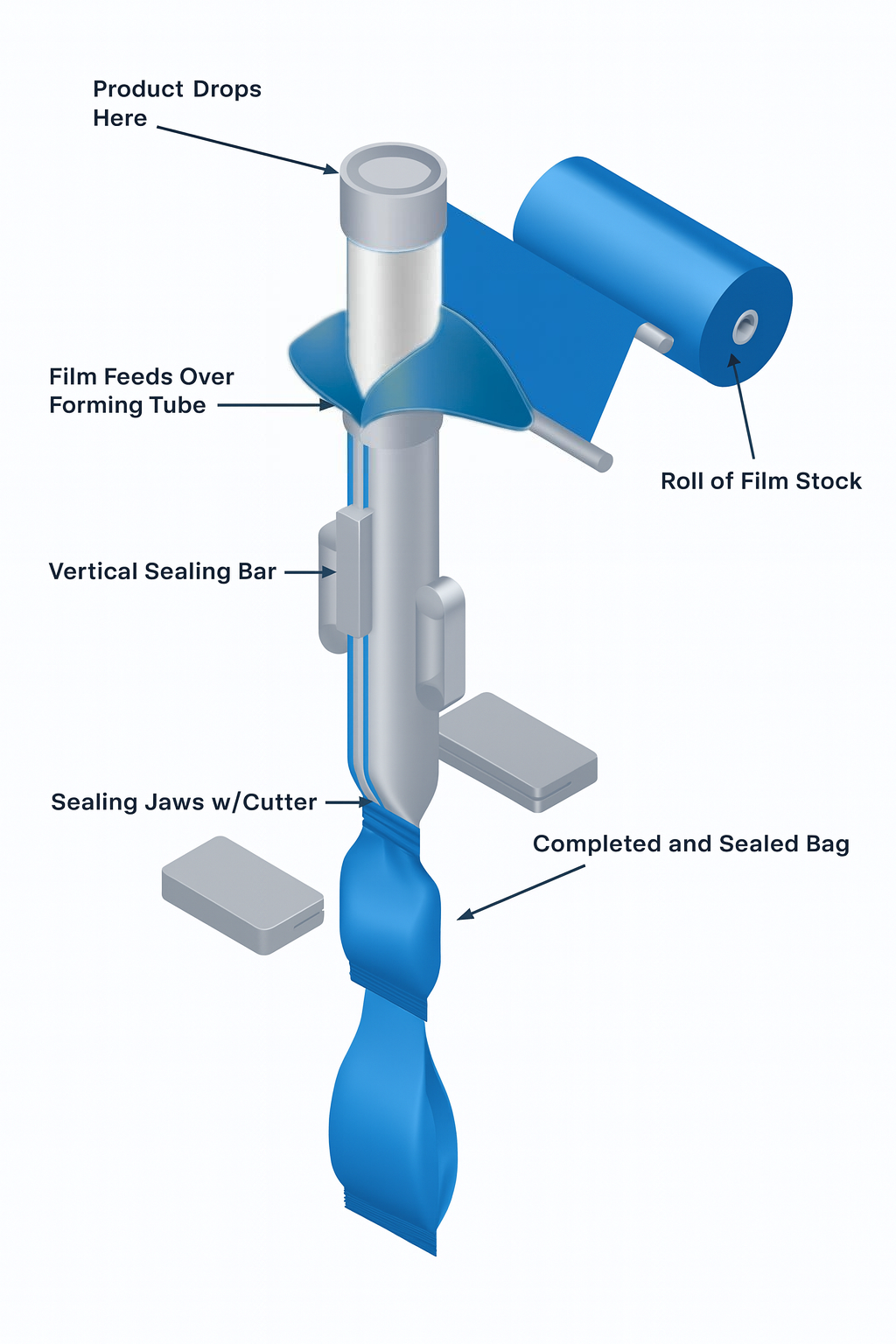

What makes the VFFS system stand out is its seamless, fully automated workflow. While the process looks complex from the outside, it can be broken down into six precise steps:

Film Unwinding & Feeding

It all starts with a roll of flat packaging film. The film transport system unwinds it under controlled tension and guides it smoothly through rollers to prevent wrinkles before entering the forming section.Bag Forming

The film is guided over a forming tube/collar, which shapes it into a cylindrical structure. The overlapping edges are positioned for sealing.Vertical Sealing

Heated sealing bars fuse the overlapping edges of the film, creating a continuous sealed tube. This forms the backbone of the bag structure.Product Filling

Above the forming tube, a dosing or weighing system—such as a multihead weigher, auger filler, or liquid pump—accurately drops the product into the newly formed bag.Horizontal Sealing & Cutting

The horizontal sealing jaws close and seal the top of one bag while simultaneously sealing the bottom of the next bag. A knife then cuts them apart into individual finished packages.Finished Product Discharge

The sealed bag drops onto a conveyor, ready for inspection, boxing, or palletizing. This cycle repeats continuously, achieving impressive speeds of dozens to hundreds of bags per minute.

In short, the VFFS machine converts a single roll of packaging film into thousands of consumer-ready bags—fast, precise, and efficient.

Core Components of a VFFS Machine

| Component | Function |

|---|---|

| Film Transport System | Unwinds and maintains tension for smooth film feeding, ensuring wrinkle-free bags. |

| Forming Tube/Collar | Shapes the flat film into a cylindrical bag; bag width depends on tube size. |

| Vertical Sealing Unit | Heated bars fuse the film edges into a back seal; sealing temperature and pressure are critical. |

| Horizontal Sealing & Cutting Unit | Seals bag tops and bottoms, while knives separate finished bags from the continuous tube. |

| Filling System Interface | Allows integration with weighers, auger fillers, or liquid pumps depending on product type. |

| PLC Control System | The “brain” of the machine. Operators adjust parameters like bag length, sealing temperature, and speed via a touchscreen HMI. |

Technical Advantages of VFFS Packaging Equipment

High Speed & Efficiency

Depending on configuration, VFFS machines achieve packaging speeds from 40 to over 300 bags per minute, far surpassing manual or semi-automatic systems.Versatility & Flexibility

By simply changing forming tubes and adjusting settings, the same machine can produce different bag sizes and formats, accommodating diverse packaging needs.Space-Saving Vertical Design

The upright structure minimizes floor space requirements, making it ideal for factories with limited space.Broad Compatibility

VFFS machines integrate seamlessly with filling systems for solids, powders, granules, and liquids, making them suitable across multiple industries.

Why VFFS Machines Dominate the Packaging Market

Cost-Effectiveness: Automated processes reduce labor costs and product giveaway.

Consistency: Precise sealing ensures bags are uniform, boosting brand presentation.

Scalability: VFFS systems grow with your production needs, adapting to higher volumes.

Market Demand: From food and beverage to chemicals and household goods, more brands are shifting toward VFFS packaging equipment for its balance of speed, accuracy, and flexibility.

Conclusion

The Vertical Form Fill Seal (VFFS) machine is a cornerstone of modern packaging automation. By combining precision engineering, automated workflows, and versatile components, VFFS machines deliver unmatched efficiency and reliability.

For packaging agents and machinery dealers, understanding the inner workings of VFFS machines is critical. Not only does it deepen your technical expertise, but it also enables you to better advise clients on the right solutions for their production needs.

👉 Are you a packaging agent or dealer looking to expand your portfolio? Partner with us to bring world-class VFFS packaging machines to your clients. Contact us today to explore dealership opportunities and competitive supply programs.