In the competitive world of food packaging machinery—from Belt Conveyors and Modular Belt Conveyors to Multihead Weighers, Linear Weighers, Pouch Packaging Machines, VFFS Machines, Rotary Packing Tables, Sachet Counting Machines, Metal Detectors, and Carton Sealing Machines—quality is not just about the machines we deliver; it is also about the partners we work with.

At FILL-PACKAGE (www.fill-package.com), we believe that building a reliable supply chain is as critical as designing a robust food packaging machine. This is why an effective Supplier Annual Evaluation System is at the core of our quality management framework. It helps us ensure stable supply, consistent quality, and long-term trust with our global customers.

In this blog, we’ll walk you through:

- Why annual supplier evaluation matters

- Key scoring criteria to assess supplier performance

- How dynamic evaluation ensures continuous improvement

- Real-world practices from the packaging machinery industry

- What this means for you as our partner

Why Build a Supplier Annual Evaluation System?

A strong supply chain is the backbone of any manufacturing enterprise. For pet food packaging machine manufacturers, where precision and reliability are non-negotiable, supplier quality directly determines equipment stability and customer satisfaction.

Without a structured evaluation system, companies risk:

- Inconsistent component quality, leading to frequent failures of critical parts such as gears, motors, or photo eyes.

- Increased downtime of production lines, especially for high-demand products like food packaging machines or automatic pouch packaging machines.

- Higher total costs due to unexpected repairs, replacements, and logistics delays.

By establishing a clear, transparent, and data-driven supplier assessment system, manufacturers can select trustworthy partners, reduce risks, and build a resilient production ecosystem.

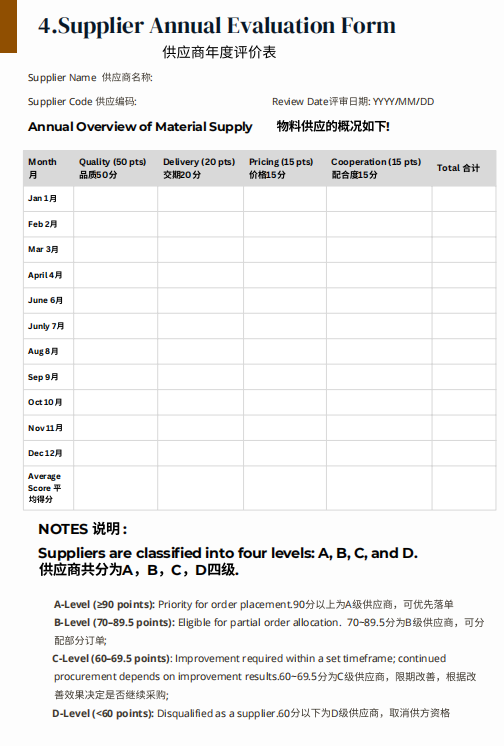

Key Scoring Standards for Annual Supplier Evaluation

To evaluate suppliers fairly and effectively, FILL-PACKAGE uses a multi-dimensional scoring system. Here’s a breakdown:

| Evaluation Dimension | Weight | Key Indicators |

|---|---|---|

| Product Quality | 40% | Conformity to specifications, defect rate, durability of packaging machines and spare parts |

| Delivery & Lead Time | 20% | On-time delivery rate, responsiveness to urgent orders |

| Service & Technical Support | 15% | Responsiveness, availability of remote support, and on-site assistance |

| Compliance & Certifications | 15% | Valid CE, ISO, FDA, UL, or industry-specific certifications |

| Cost Competitiveness & Flexibility | 10% | Pricing transparency, payment terms, and willingness to customize solutions |

This structured approach avoids one-sided decision-making. Instead of chasing the lowest price, we look at long-term Total Cost of Ownership (TCO), ensuring machines like flow wrappers or bucket elevators perform reliably for years with minimal downtime.

Dynamic Assessment: Continuous Improvement in Action

Supplier evaluation is not a one-time event; it’s a dynamic process. Markets evolve, technologies upgrade, and customer expectations rise. A supplier that performed well last year may face challenges this year.

At FILL-PACKAGE, we adopt a rolling evaluation mechanism:

Quarterly performance reviews using real-time data from our check weigher machines and metal detectors, ensuring parts and materials meet strict tolerance levels.

8D Problem-Solving Reports (JIP): When issues occur, we work closely with suppliers to analyze root causes, implement corrective actions, and track improvements.

Supplier Development Programs: For strategic partners, we offer joint training, technical guidance, and continuous process optimization to ensure they grow with us.

This approach transforms evaluation into collaborative growth rather than mere judgment.

Real-World Example: Packaging Line Optimization

Recently, a global client in the pet food packaging industry faced efficiency challenges. Their existing belt conveyor system had high wear rates, leading to downtime and delays in their pouch packaging machines and flow wrappers.

Through our supplier evaluation system, we identified the root cause: inconsistent quality in the cleated conveyor belts sourced from a local vendor. By switching to certified Modular Belt Conveyor components and collaborating with a top-tier supplier, we not only improved reliability but also reduced maintenance costs by 30%.

This case shows that a reliable supplier ecosystem directly enhances equipment uptime and customer trust.

What This Means for You

As a buyer of food packaging machines—whether Multihead Weighers for precise portioning, VFFS Machines for flexible packaging, or Rotary Packing Tables for streamlined operations—you need more than a machine. You need the assurance that every component, from the smallest screw to the most advanced servo motor, is sourced from trusted suppliers and validated through rigorous evaluation.

At FILL-PACKAGE, our Supplier Annual Evaluation System ensures:

- Every Bucket Elevator, Belt Conveyor, and Linear Weigher meets international quality standards

- Photoelectric sensors and Metal Detectors are tested under real production conditions

- Spare Parts are sourced from certified, traceable partners

- Consistent and reliable machine performance for long-term ROI

Conclusion: Trust Built on Quality

In the food industry, a packaging machine is not just equipment—it’s a guarantee of efficiency, safety, and reliability. By choosing a partner like FILL-PACKAGE, you gain more than advanced technology; you gain the confidence that your supply chain is solid, your production is stable, and your customers receive products of consistent quality.

✨ Ready to learn more about how FILL-PACKAGE ensures quality at every step? Contact us today at www.fill-package.com and let’s build trust together.