In the food packaging machinery industry, success is never the effort of a single company alone. Behind every reliable food packaging machine—whether it’s a Belt Conveyor, Modular Belt Conveyor, Bucket Elevator, Working Platform, Rotary Packing Table, Multihead Weigher, Linear Weigher, Pouch Packaging Machine, VFFS Machine, Flow Wrapper, Check Weigher Machine, or Metal Detector—there is a carefully managed supplier ecosystem.

At FILL-PACKAGE (www.fill-package.com), we understand that every gear, sensor, and spare part matters. That’s why we’ve built a Supplier Grading and Certification System, a framework that goes beyond price negotiation to ensure every component meets international quality, safety, and performance standards.

In this blog, we’ll walk you through:

- Why supplier grading matters in the packaging machinery sector

- The three-tier supplier classification framework

- Practical certification and audit standards

- Supplier management strategies for long-term success

- How FILL-PACKAGE uses this system to guarantee quality

Why Supplier Grading Matters

When customers invest in a food packaging machine, they expect stability, safety, and consistent performance. However, if even one component—a cleated conveyor belt, a servo motor, or a photoelectric sensor—fails due to poor supplier quality, the entire production line may stop. This means:

- Lost productivity on food production lines, where multihead weighers and VFFS machines often run 24/7.

- Higher maintenance costs, as low-grade spare parts wear out quickly.

- Reputation risks for both packaging equipment manufacturers and food packaging companies.

A robust supplier evaluation framework ensures that only reliable, certified partners join the supply chain, protecting your investment and guaranteeing long-term performance.

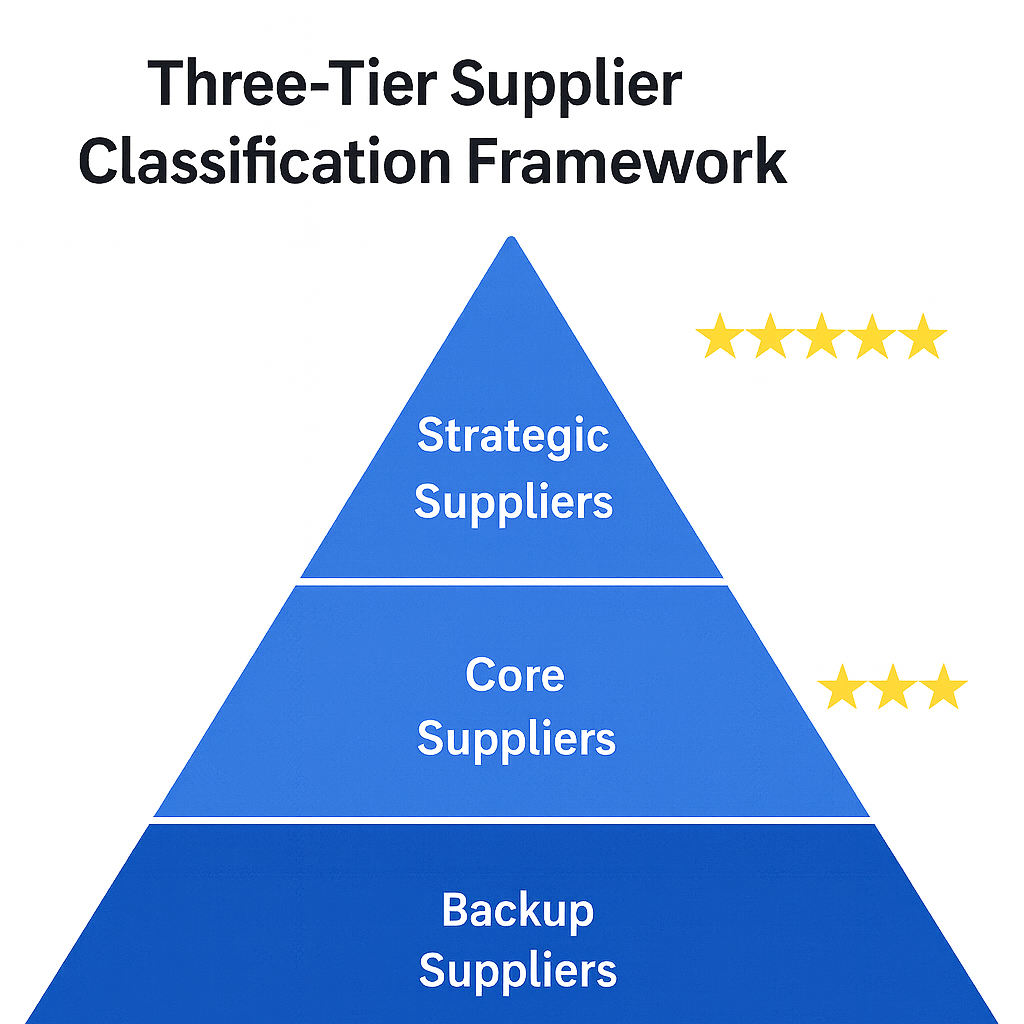

Three-Tier Supplier Classification Framework

We categorize suppliers into three levels to maintain a balanced, competitive, and resilient supply chain:

| Tier | Description | Role in Supply Chain |

|---|---|---|

| Strategic Suppliers | Global or industry-leading food machinery manufacturers and component suppliers with proven track records. | Provide critical components such as multihead weighers, check weigher machines, and metal detectors with guaranteed performance and certification. |

| Core Suppliers | Reliable regional partners for key items like belt conveyors, modular belt conveyors, bucket elevators, and working platforms. | Ensure stable delivery and localized support, balancing cost and quality. |

| Backup Suppliers | Secondary sources, often smaller vendors, certified for specific spare parts or materials. | Provide supply chain flexibility and reduce dependency on single sources. |

This tiered approach ensures that we always have reliable partners while also encouraging continuous competition and innovation.

Certification & Audit Standards

Supplier trust cannot rely on promises alone. At FILL-PACKAGE, every supplier must meet strict certification standards:

- Quality Certifications: ISO 9001, CE, FDA, or equivalent international approvals.

- Material Compliance: Food-grade stainless steel (304/316) for contact parts in food packaging machines.

- Safety Systems: Integration of reliable metal detectors, check weigher machines, and safety sensors to ensure compliance with global regulations.

- Sustainability: Preference for suppliers offering recyclable packaging films, sachet packaging solutions, and eco-friendly materials.

Beyond certifications, our annual audits cover production capacity, process control, and traceability of raw materials. This guarantees every flow wrapper, pouch packaging machine, or carton sealing machine we deliver meets the highest standards.

Smart Supplier Management Strategies

Building a supplier ecosystem is not just about selection; it’s about long-term collaboration. Here are three strategies we apply:

- Performance Tracking: We use real-time data from check weigher machines and production lines to evaluate defect rates and ensure continuous compliance.

- Transparent Communication: With clear KPIs—such as on-time delivery rate, response speed, and spare part availability—we maintain open, measurable relationships with our suppliers.

- Supplier Development Programs: For strategic partners, we provide technical training, joint R&D opportunities, and co-innovation in areas like automatic food packaging machines and modular belt conveyors.

These practices ensure our suppliers are not just vendors, but true collaborators in delivering excellence to our customers.

FILL-PACKAGE’s Commitment to Quality

For over a decade, FILL-PACKAGE has been building its reputation as a food packaging machine manufacturer known for reliability and innovation. Our Supplier Grading & Certification System plays a vital role in this journey. By working only with certified, high-performance suppliers, we can guarantee that every belt conveyor, bucket elevator, VFFS machine, multihead weigher, or flow wrapper we deliver is backed by world-class quality standards.

This means:

- Lower risk of downtime on your food production line

- Longer service life for critical spare parts and components

- Greater confidence when expanding into new markets with demanding quality standards

Conclusion: Your Reliable Partner in Packaging

Supplier management is not just an internal process—it’s a promise to our customers. When you choose FILL-PACKAGE, you are choosing a partner that invests in rigorous supplier evaluations, international certifications, and transparent quality standards.

✨ Looking for a trusted partner in the packaging industry? Let’s talk! Visit www.fill-package.com and discover how our certified supply chain supports world-class food packaging machines.