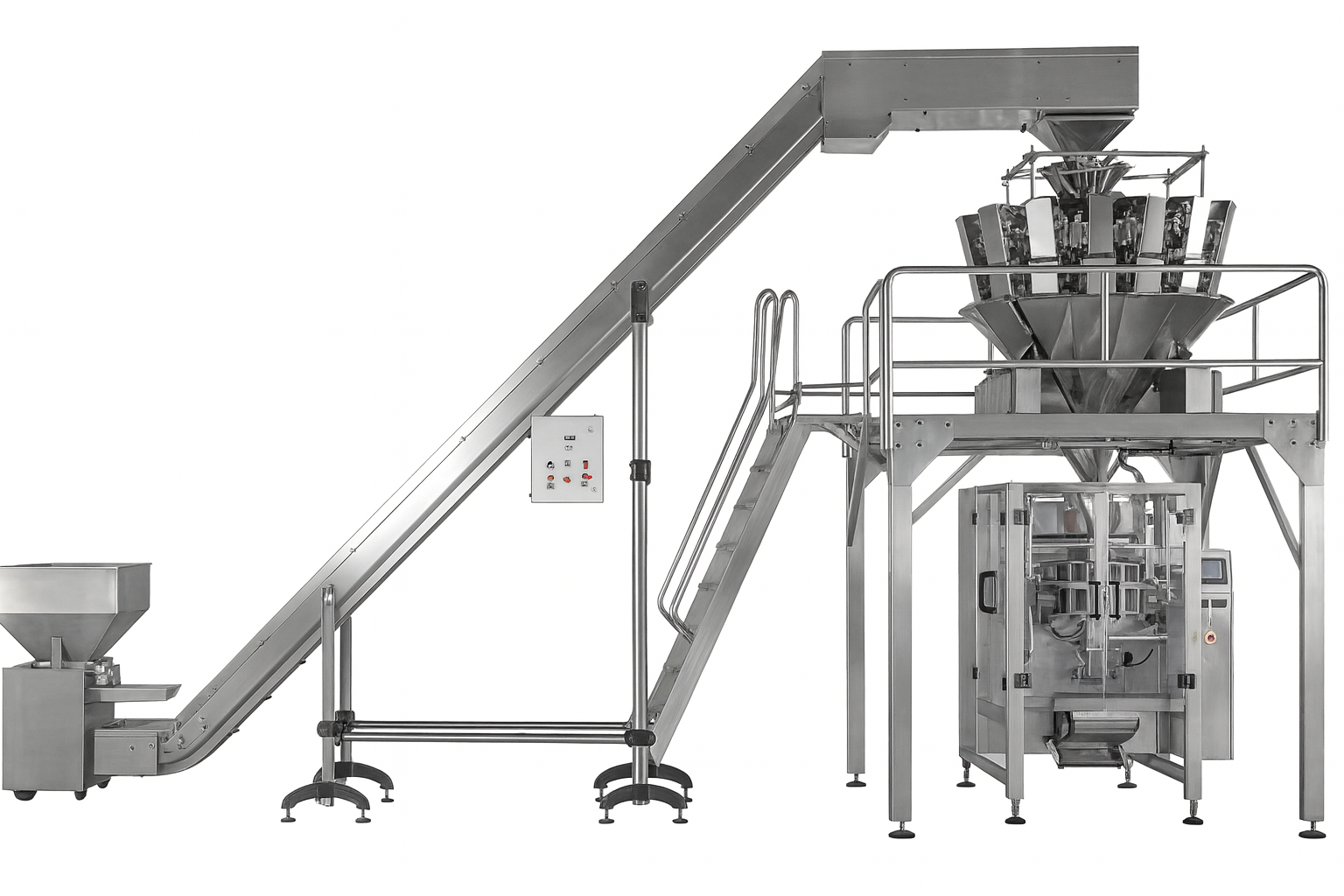

In modern food production, the food packaging machine industry is no longer just about “packing products into bags.” Behind every bag of snacks or pet food, there’s a smart, efficient, and hygienic conveyor system ensuring seamless production. Among all equipment—whether it’s a belt conveyor, modular belt conveyor, cleated conveyor belt, bucket elevator, working platform, flow wrapper, VFFS machine, pouch packaging machine, multihead weighers, linear weighers, sachet counting machine, metal detector, or carton sealing machine—the conveyor plays a central role in connecting every process.

In this blog, we’ll walk you through the essentials of choosing the right conveyor belt system, focusing on material selection, performance differences, and cost analysis—so you can make smarter investment decisions.

Why Conveyor Belt Selection Matters

A conveyor isn’t just a “moving belt”—it’s the artery of your food packaging line. Whether you’re handling potato chips, biscuits, pet food, or frozen snacks, the right conveyor ensures smooth product transfer, accurate feeding into multi-head weighers or sachet packaging machines, and stable operation under different environments (temperature, humidity, dust, or oil).

The wrong choice, however, can lead to:

- Frequent downtime from belt breakage

- Inconsistent product flow, affecting packaging for chips or other foods

- Higher maintenance and replacement costs

- Reduced overall equipment efficiency

Types of Conveyor Belt Systems

1. Plastic Modular Belt Conveyor

- Features: Made of interlocking plastic modules, resistant to water, oil, and cutting. Easy to clean and replace.

- Applications: Ideal for food conveyor lines handling snacks, confectionery, or pet food that require high hygiene standards.

- Cost: Higher than PVC belts, but longer service life means lower long-term costs.

2. PU (Polyurethane) Belt Conveyor

- Features: Smooth surface, food-grade, resistant to grease and oil, excellent for direct contact with food.

- Applications: Widely used in automatic potato chips packing machines, meat, bakery, and dairy processing lines.

- Cost: Moderate, with good balance between hygiene and affordability.

3. PVC Belt Conveyor

- Features: Cost-effective, lightweight, suitable for dry and lightweight products. Not ideal for oily or high-temperature environments.

- Applications: Chips packaging machines, dry snacks, bakery items, and general packaging for chips in small factories.

- Cost: Lowest initial investment, but may need more frequent replacement compared to PU or modular belts.

Best Practices for Selecting the Right Conveyor

1.Match Product Properties

- For oily products (like potato chips or pet food with fat/oil), PU or modular belts are safer.

- For dry snacks (biscuits, bread, powders), PVC belts can be a cost-effective option.

2. Check Hygiene Standards

- Ensure the conveyor belt materials are food-grade certified (FDA, EU standards).

- Modular belts are easier to clean, making them ideal for high-hygiene environments.

3.Think About Integration

- Your conveyor should seamlessly connect with multihead weighers, linear weighers, pouch packaging machines, and flow wrapper systems.

- For vertical movement, a bucket elevator may be needed, while a rotary packing table (Lazy Susan table) helps with accumulation and manual packing.

4.Balance Cost & Durability

- Don’t just chase the lowest price. Consider total cost of ownership: initial investment + maintenance + spare parts + energy efficiency.

- For long-term savings, stainless steel belt conveyors or modular belts often provide better durability and less downtime.

Modern Trends: Smart & Efficient Conveying

Automation is transforming food packaging equipment across industries—whether for biscuits, snacks, or pet food. Today’s conveyor systems often integrate with sensors, metal detectors, and check weigher machines to ensure every package meets quality standards. Some lines even connect directly to VFFS machines and flow wrappers, creating a fully automated and highly efficient process.

Key Takeaways

- Understand your product: material, size, shape, and surface features matter.

- Pick the right belt: choose between plastic modular, PU belt, PVC belt, cleated conveyors, or flat belt conveyors depending on your application.

- Think long-term: factor in energy use, maintenance, and spare parts—not just the purchase price.

- Plan for integration: ensure your food conveyor works seamlessly with weighers, packaging machines, and supporting equipment.

Let’s Talk!

At Fill Package, we specialize in food packaging machines—including belt conveyors, modular belt conveyors, cleated conveyor belts, bucket elevators, working platforms, rotary packing tables, multihead weighers, linear weighers, pouch packaging machines, VFFS machines, flow wrappers, and reliable spare parts.

If you’re planning to set up or upgrade your production line, we’d love to share insights and help you find the most suitable solution.

👉 What’s your biggest challenge when choosing a conveyor belt system for food packaging? Share your thoughts in the comments—we’d love to hear from you!