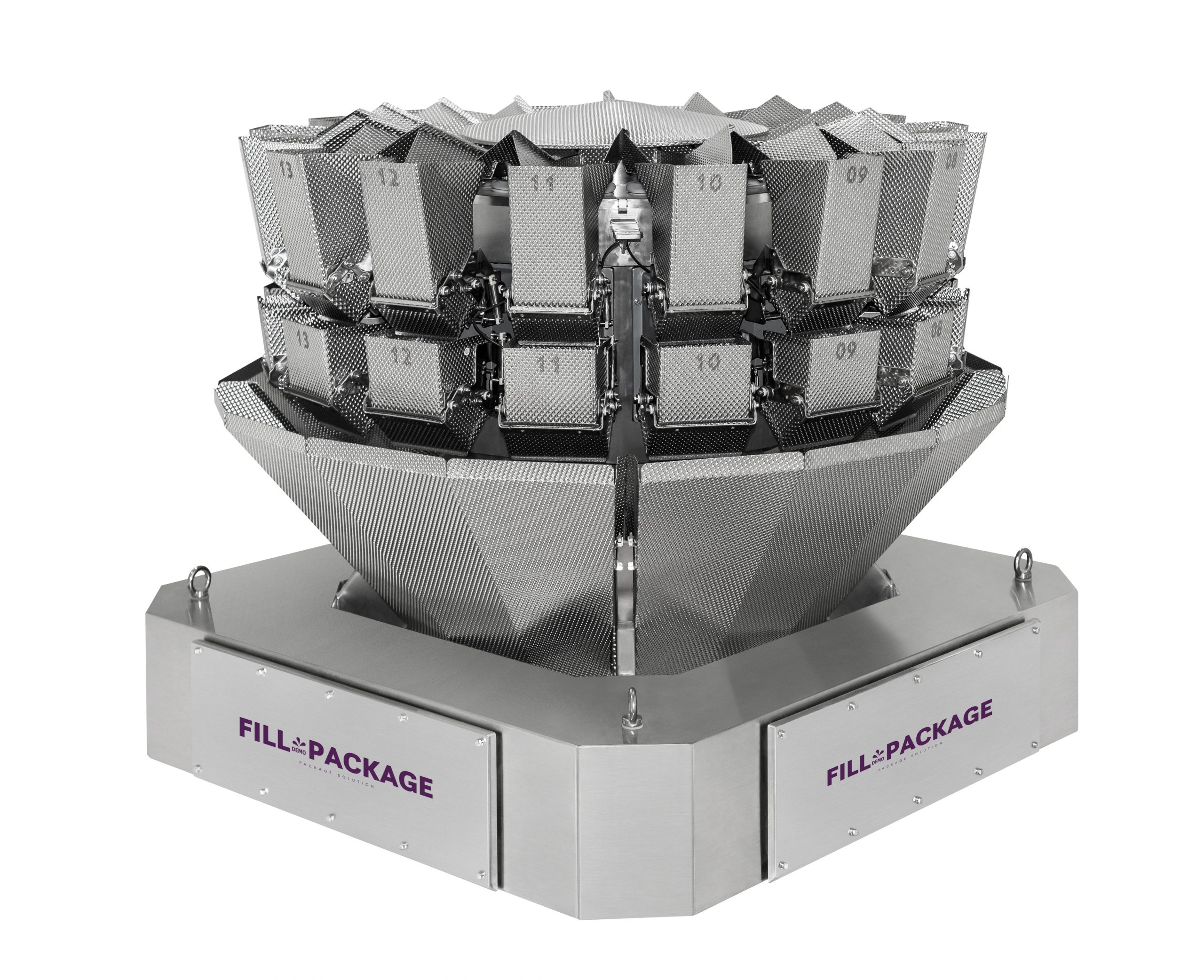

Product Overview

The FPW-16 Multihead Weigher is engineered for applications requiring high-speed and large-volume packaging. With 16 weighing heads, it offers more combination possibilities, leading to faster operation and higher accuracy. This model is particularly suitable for packaging products like salads, vegetables, and other bulky items.

Key Features

High-Speed Packaging Capability

- Increased Combination Options: More heads mean more combinations, resulting in faster operation.

- Enhanced Accuracy: Achieves higher precision in weight measurements, reducing product giveaway.

Suitable for Large-Volume Products

- Ideal for Bulky Products: Designed to handle large-volume items such as salads, vegetables, and other similar products.

- Robust Construction: Built to manage heavier loads without compromising on speed or accuracy.

Flexible Feeding Methods

Feeding Options: Available with both vibratory and rotary feeding systems to accommodate different product characteristics.

Diverse Contact Surface Designs

Surface Options: Contact parts can be customized with flat, small dimple, or honeycomb dimple surfaces to suit various product types and prevent sticking.

- Technical Specifications

- Certificates

| Material | Stainless steel 304 |

| Bracket size | 1.6L ,2.5L and 5.5L |

| Max speed | 140 bags/min (depened on material &weigh) |

| Water poof | IP63/IP65 optional |

| Accuracy | 0.3g-1g (depened on material ) |

| Control display | 10 inch color screen |

| Power supply | 220v/110v 50Hz or 60Hz option |

| Preset programs | 100 |

| Surface | Smooth /Dimple |

All the Weighers with CE certifications .

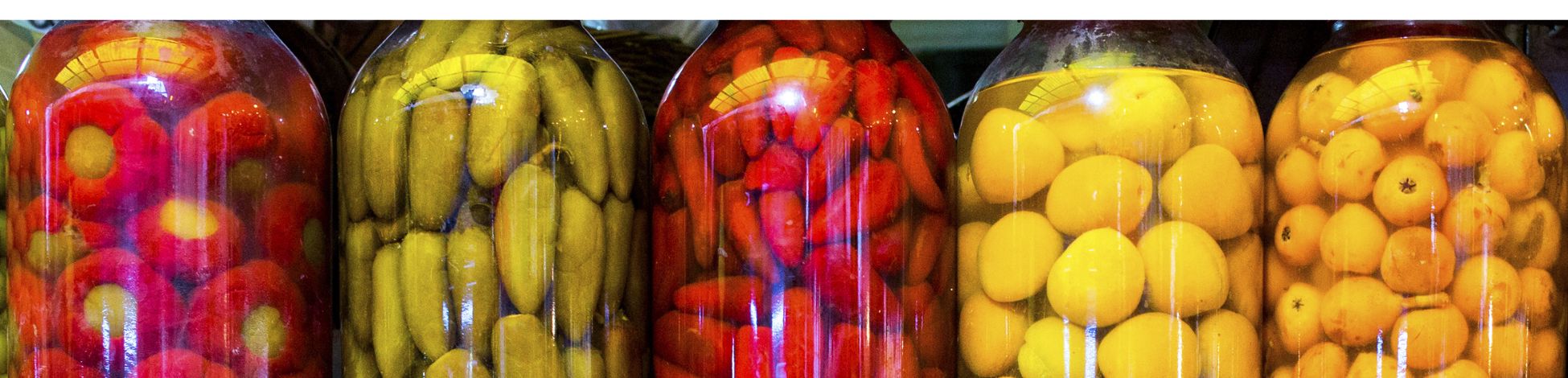

Your Best Choice For Salad

14Head & 16 Head large volume brucket weighers are usually used for Salad or large .they are built for cool and humid environments.that vegetables produced in .we made the weighers with different mechanical structure form whole leaves to cut lettuce .work smoothly.

In order to suit your exact needs ,main feeder vibration plate driving method, linear plate shape .bucket length ,chute height .All can redesigned specifically for your needs with low price in market

Advantages for Agents & OEMs

Customizable Solutions: Tailored feeding methods and contact surface designs based on client needs.

Technical Support: Comprehensive support including installation guidance, operation training, and after-sales service.

Quality Assurance: All equipment undergoes rigorous quality checks to ensure stable and reliable performance.

High Speed

16 head weigher with small buckets usually used in high speed request .however high speed is relative .not the highest one in the world . it be effected in different factors .like :material ,material size ,material density .weigh .we will offer or modify some features in combination with the characteristics of products to maximize the speed of dumping and weighing per minute

Frequently Asked Questions – FPW-16 Multihead Weigher

The 16 head multihead weigher provides significantly more combination options, allowing for:

Higher packaging speeds (up to 120 packs/min)

Greater accuracy, especially for medium-to-large weight targets

It’s ideal for operations that need both speed and volume—such as packaging salads, frozen vegetables, or ready meals.

Yes. The FPW-16 is commonly used for bulk product weighing such as leafy vegetables, mixed salads, or large food portions.

We offer custom hopper sizes, reinforced discharge chutes, and various contact surface textures (flat, small dimple, or honeycomb dimple) to prevent sticking or product damage.

The FPW-16 supports:

Vibratory feeding – best for free-flowing dry items

Rotary top cone feeding – preferred for lighter, bulky, or irregular products

We’ll recommend the most effective feeding method based on your product’s flow characteristics.

Absolutely. This automatic multihead weigher is built for seamless integration with:

VFFS vertical form-fill-seal machines

Premade pouch machines

Tray denesters and sealers

We provide CAD drawings and electrical interface guidance for all integrations.

Contact parts are tool-free and quick-release, allowing for fast cleaning between runs

Stainless steel body is easy to wash down

Main PCB boards are shared across models, so spare management is simple

Recommended maintenance: Clean daily, inspect weekly, recalibrate quarterly

We’ll test your material in our lab and provide:

Live demo video

Test report with target weight + accuracy range

Pre-set parameter suggestions

This ensures the machine will perform before it even arrives.

Yes. For agents and system integrators, we offer:

OEM branding (label/logo/language customization)

Test videos for your client

Pre-set product recipes

Quick response after-sales support (within 8 hours)

Local spare parts stocking recommendation