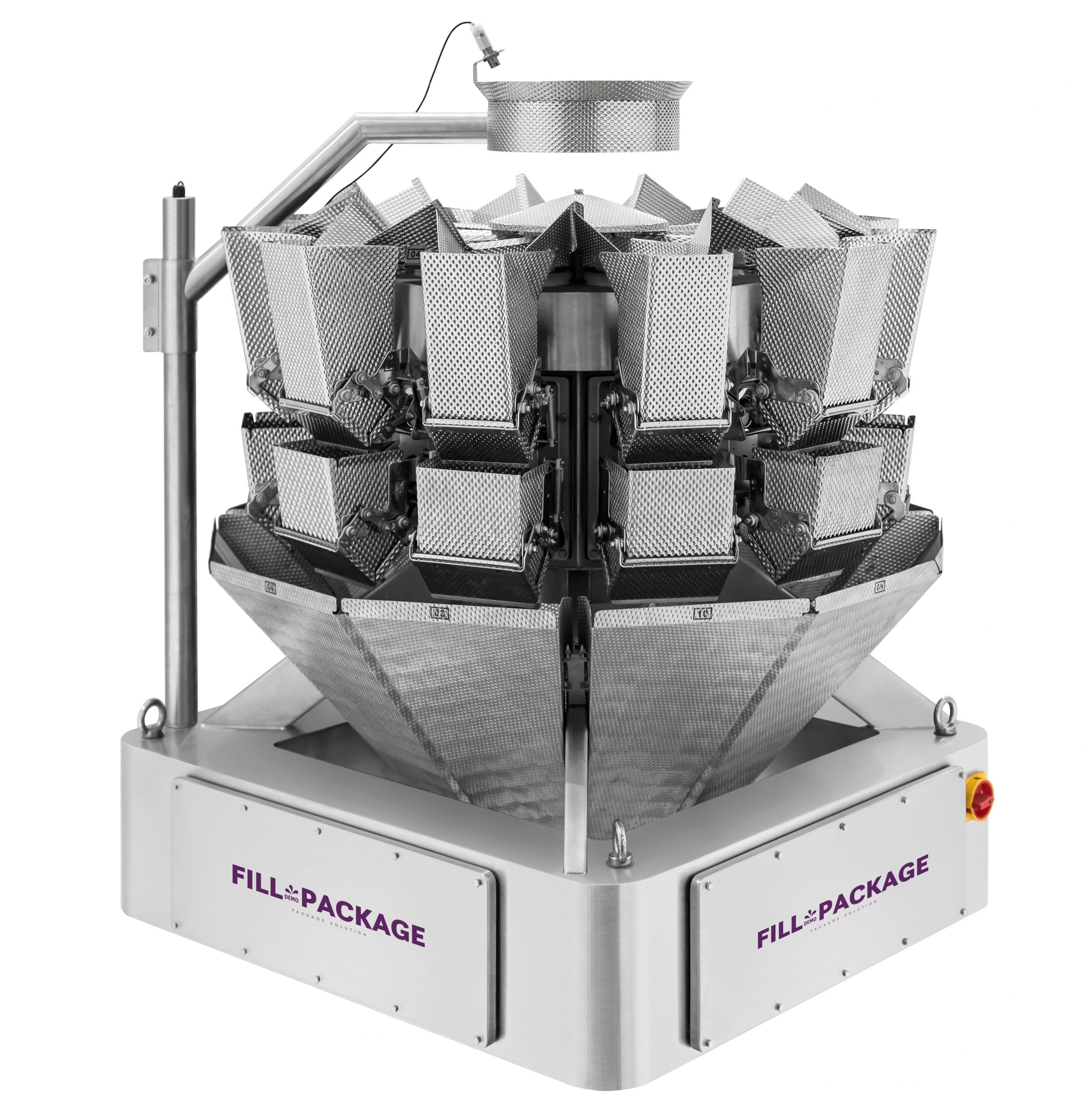

More Benefits With Our Weigher Machine

- More combination(compare with 10 head) ,However,price is similar to 10 head .I specifically designed to enter the entry-level market.

- Save labor costs.Full automatic package operation form feeding to packing .

- Modular design ,stable Can Bus electronic design since 2011

- Dia- coded AD module .no need to manual welding .easy to maintenace .

- Easy operation with color menu duiance on HMI ,12″ color-touch-screen.

- Mother board store production statistics and date .you can record and optimiztion .

- Datasheet

- Certificates

| Material | Stainless steel 304 |

| Bracket size | 1.6L ,2.5L and 5.5L |

| Max speed | 65 bags/min (depened on material &weigh) |

| Water poof | IP63/IP65 optional |

| Accuracy | 0.3g-1g (depened on material ) |

| Control display | 12 inch color screen |

| Power supply | 220v/110v 50Hz or 60Hz option |

| Preset programs | 100 |

| Surface treatment | Smooth /Dimple |

| Special costing | Option for different material |

All the products with CE certifications .

Multiway Cooperation

Our multihead weigher packing machine can be easily integrated with your existing machines .like VFFS machines .Bucket elevators and rotary package machine .

Not only multi-head scales, but we can also provide a complete automation system according to your needs, including vibrating feeders, conveyors or bucket elevators, platforms, packaging machines, metal detectors, check weigher.etc . and free design drawings for reference and confirmation .

Check with us today .

Our Guarantee To You

As packaging machinery manufacturers,we understand well how important after-sale service to your business.dozens tons of materials waiting to pack once machines out of work ,customers give crazy calls to request parts and technician check .Or delivery is delayed as supply chain is broken .

In order to make weighers can run stably and reliably in your hands .All of our machines need to tested and inspected before shipment .our professional quality control team and strict quality management to make sure each machine meets our high standards and your requirements .we usually test every component and system ,including electrical systems ,machanical components .load cell ,software and control systems .only the machine pass all tests and inspection can be shipped to you .our goal is to provide quality products and excellent customer service to make you satisfaction and trust in our brand。

How Multihead Weigher Increase Your Profits ?

For example .you need to weigh 500g peanut into bag , open pre-made bag ,fill nuts ,weigh by hand ,check accuracy ,continue to fill when less than target weight ,take out extra when more than target .How many bags you can do per hour ?if fast 150packs/hour.

However.one line automatic package machine with base model 10 head combination weigher ,can work approx 2800bags /hour (19 times ) like 20 staffs .

Our Weighers Family ?

Our combination weighers are available with 10,11,14,16 24 or more for customer request ,Hoppers are available in sizes form 0.2L .0.5L .1L .1.6L .2.5L and 5.5L,you can order depend on package size and weigh .

Combination scales can be classified in the following ways:

Number of buckets: Classify according to the number of buckets on the combined scale, such as 10-head combined scale, 14-head combined scale, etc.

Bucket capacity: Classify according to the capacity of the combined weighing bucket, such as small-capacity combined scales, large-capacity combined scales, etc. The capacity of the bucket is generally in liters (L), such as 0.2L, 1.0L, 1.6L, 2.5L, 5.5L, etc.

Application: Classify according to application where the combination scale is applied, such as chips combination scale for chips ,candy combination scale, noodle ccombination scale etc. Combination scales in different fields may have different special requirements.

Measurement accuracy: Classify according to the measurement accuracy of combination scales, such as high-precision combination scales, standard combination scales, etc. Combination scales with different accuracy can meet different measurement accuracy requirements.

Use environment: Classuchsify according to the use environment of the combination scale, as fragile products combination scale, waterproof combination scale,etc. Combination scales in different environments may require specific protective measures.

Special type products: Classify according to the special type of combination scales, such as cannabis combination scales, precious metal combination scales, etc. These special types of combination scales may have specific functions or uses.

There are many factors to consider when you are purchasing for a multihead weigher to better suit your weighing system to your specific product and packaging goals, the following are what we consider to be the most important:

1.Number of heads.

Combination scales generally include many heads of weighing buckets., the number of heads is between 10-30 heads. The more heads, the faster the working speed and the higher accuracy. , while volume and price will also increase.

2.Accuracy

The accuracy of the combination is usually between 0.2-1.5 grams, depending on materials. If you need special high precision such as 0.0X grams, you must choose a high-precision combination scale.

3.Surface type .

The style of the surface depends on the characteristics of the product. The purpose is to make the product flow better on the weigher body. The dimple surface is suitable for a little sticky products, such like: candy and fruit.however, the smooth surface is suitable for dry solid products, like : nuts ,chips etc .

4.Bucket size and shape.

Usually target weight and the density of the product decide the size of the bucket. The principle of stability judgment is that the ideal state of the first weighing is not to exceed the capacity of the buckets 2/3, the best combination of hoppers is 3-5 pcs buckets, At the same time, the shape of the hopper should also be considered. For example, sticky food uses a hopper with a scraping door to prevent the material from sticking to the hopper.

5.Waterproof level

The IP level is to classify the waterproof and dustproof degree of the mechanical and electrical parts of the machine, which depends on the working environment, product characteristics and cleaning methods, such as working in a humid working environment for a long time, etc.

6.Software

The control system and software of the combination scale are very important to operate and manage the weighing process. Generally speaking, advanced control systems and software can provide higher levels of automation, reduce operator workload, increase production efficiency, and provide more functions, such as data management, statistical analysis, etc.

7.Equipment durability and maintenance convenience

Considering the service life and maintenance cost of the equipment, a combination scale with high durability and easy maintenance should be selected. This includes the mechanical construction of the equipment, the quality of the electrical components, and the design for ease of cleaning and maintenance.

8.Production capacity and speed

The production capacity and speed of the combination scale are also factors that need to be considered. According to the needs of the production line and the output of the product, choose the appropriate combination scale to ensure the efficient operation of the production line.

9.Cost and budget

When buying a combination scale, cost and budget are also factors that need to be considered. Not only the purchase cost of the equipment itself, but also the operating cost and maintenance cost of the equipment should be considered.

10.Manufacturer reputation and after-sales service

It is also very important to choose a manufacturer with a good reputation and a supplier that provides good after-sales service. This can ensure the quality and performance of the equipment, and provide timely technical support and maintenance services during the use of the equipment.