Your packaging line is running smoothly, and then it happens: you start seeing bags coming off your VFFS machine with tears and splits right at the horizontal seal. It’s a frustrating problem that stops production, creates waste, and can feel difficult to diagnose. The good news is that the cause is usually one of a few common issues, and you can often fix it yourself.

Before you call for service, here is a quick troubleshooting guide written from an operator’s perspective. These are the 5 most common reasons for bag tearing and how to fix them fast.

5 Common Fixes for Torn VFFS Bags

Work through these solutions one by one. Remember to only make small, single adjustments at a time to see what works.

Fix #1: Lower the Air Pressure

This is the #1 most common culprit. Over time, it’s easy to think that “more pressure equals a better seal,” but the opposite is often true. Too much force causes the sealing jaws to slam shut, physically weakening or even cutting the film at the edges of the seal. It creates a brittle area that tears easily when the bag is pulled or filled.

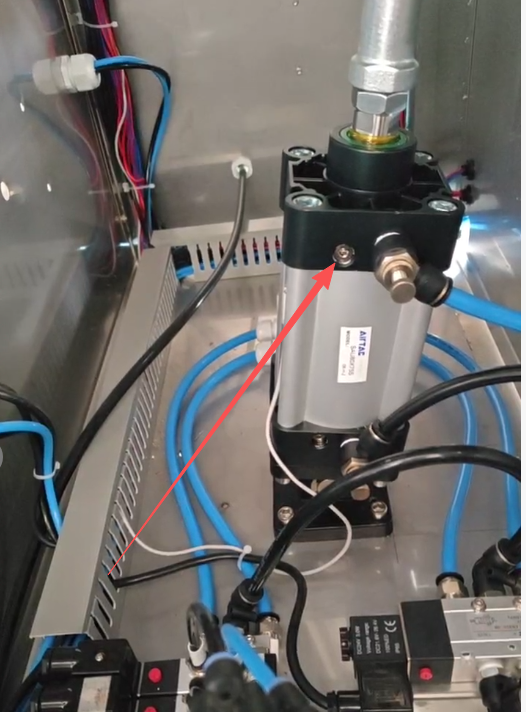

- The Fix: Go to your machine’s pneumatic controls and gradually decrease the air pressure for the horizontal sealing cylinder. A small reduction is often all that’s needed to stop the damage while maintaining a strong seal.

Fix #2: Check for Damaged Sealing Jaws

After millions of cycles, the metal surfaces of your sealing jaws can develop tiny nicks, burrs, or a buildup of burnt-on material. Even a small imperfection can act like a razor blade, creating a weak point on the film that starts a tear.

- The Fix: Power down the machine and wait for the jaws to cool. Run your finger carefully along the sealing surface. If you feel any roughness or sharp spots, the jaws need attention. You may be able to clean off buildup with a brass brush, but if the metal itself is damaged, the jaws will need to be professionally resurfaced or replaced.

Fix #3: Check the Jaw Alignment (Parallelism)

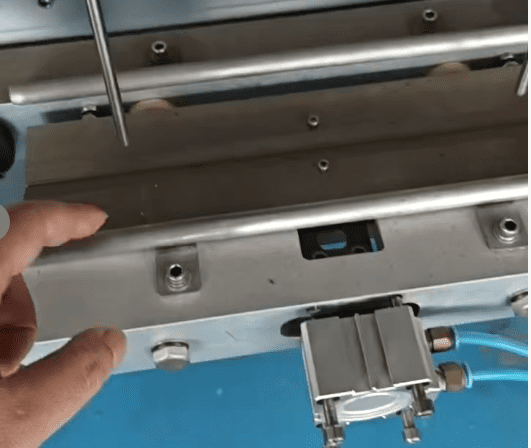

If the sealing jaws don’t close perfectly parallel, the pressure will be uneven. One side might be too loose to seal properly, while the other side gets crushed, causing a tear. This is a common issue in an older automated VFFS system.

- The Fix: With the machine off, manually close the jaws. Try to slide a thin piece of paper between them at both the left and right ends. You should feel the same amount of resistance on both sides. If one side is tighter than the other, the jaws are misaligned and need to be adjusted until they are perfectly parallel.

Fix #4: Make a Small Temperature Adjustment

While less common than pressure issues, incorrect temperature can also cause problems. If the seal is too cold, it won’t be strong enough and can pull apart. If it’s too hot, the film becomes brittle and cracks easily.

- The Fix: If you suspect a weak seal, try increasing the temperature by just 2-3°C. Be very careful here—too much heat will create more problems. If the film looks burnt or melted, your temperature is too high. Using a surface pyrometer to check the actual jaw temperature is the best way to verify.

Fix #5: Look for a Pattern

Don’t just inspect one bad bag; gather 10 or 20 of them. Is the tear always in the exact same spot? Is it always on the left side? A consistent pattern is a huge clue. A recurring tear on one side, for example, strongly points to an issue with that specific side, such as jaw misalignment or a localized burr.

When It’s Time to Upgrade Your Packaging Solution

If you find yourself constantly making these adjustments, or if your machine is simply too worn to hold its settings, it may be time to consider an upgrade. An older machine can cost you more in downtime and wasted product than you realize.

A modern vertical form Fill Seal Machine offers far superior control over pressure, temperature, and alignment, ensuring a perfect seal every time. Investing in a new VFFS packaging solution can be the most effective long-term fix, eliminating these chronic headaches and boosting your overall efficiency.

👉 Struggling with an older machine? Explore our range of modern VFFS machines designed for reliability and precision, or contact our engineering team to find the perfect vertical packaging solution for your needs.