In modern industrial production, efficiency and automation are the ultimate goals for manufacturers.

Among the many automated machines on a packaging line, there’s one device that may look simple at first glance, yet plays a critical role at the end of the process — ensuring products move smoothly and efficiently to the next stage.

This is the Lazy Susan Table — also known as the rotary packaging table or industrial rotary table.

It’s far more than just a spinning platform. It’s a hidden hero that connects workflows, buffers products, and boosts packaging efficiency.

This article will walk you through what an industrial Lazy Susan Table is, its origins, working principle, integration with other machines, common applications, customer concerns (and our solutions), and frequently asked questions — so you can see why this device is an indispensable part of a high-performance packaging line.

1. What Is a Lazy Susan Table?

In industrial packaging, a Lazy Susan Table (also called a rotary table or packaging conveyor table) is a rotating platform designed for product collection, buffering, sorting, or transfer.

It’s typically positioned at the end of a packaging machine, receiving finished products and evenly distributing them for manual packing, case packing, palletizing, or feeding into the next conveyor.

Unlike the household Lazy Susan used on dining tables, the industrial version focuses on load capacity, stability, hygiene, and seamless integration into automated lines.

2. Origins and Evolution

The term “Lazy Susan” dates back to the early 20th century, originally describing a rotating serving tray for easy sharing of food.

When this concept was brought into the industrial world, especially packaging lines, the design was reinforced, upgraded in materials, and powered by precision drive systems.

It evolved into a robust, high-efficiency material handling platform — keeping the rotation function but optimizing it for heavy-duty, high-volume, and continuous operation in demanding production environments.

3. How It Works: Efficiency in Motion

An industrial Lazy Susan Table is built for continuous, smooth, and reliable product handling at the end of a packaging line.

Its operation combines mechanical precision, controlled rotation, and ergonomic access — plus a clever surface profile design to improve product flow.

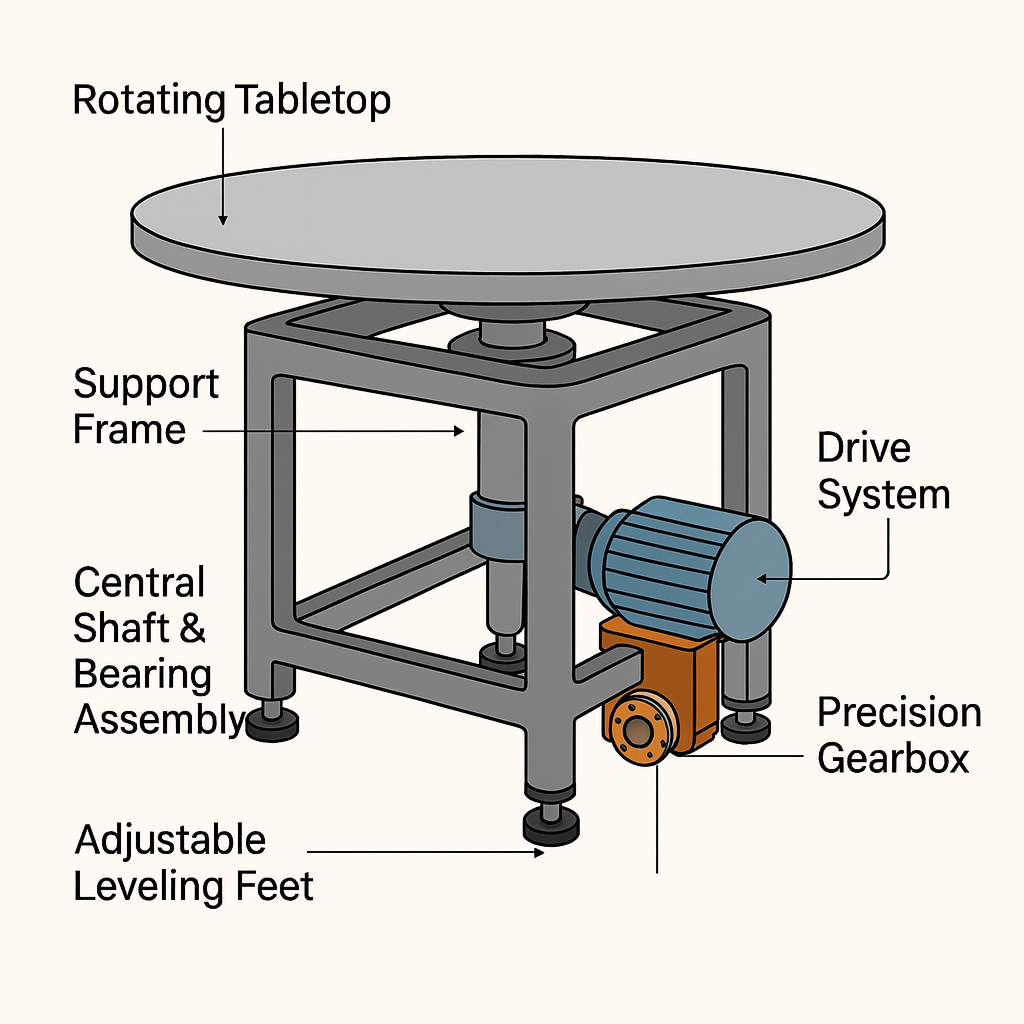

Core Structure

- Rotating Tabletop with Profiled Surface – Typically made from SUS304 food-grade stainless steel. The center is slightly concave (lower) and the outer edge is slightly raised. Combined with rotational force, this design naturally guides products outward toward the edge, preventing pile-ups and making product collection easier.

- Support Frame – Heavy-duty welded structure that ensures stability, even under maximum load. Equipped with adjustable leveling feet to compensate for uneven factory floors.

- Drive System – Electric motor with a precision gearbox for smooth, vibration-free rotation.

- Central Shaft & Bearing Assembly – High-precision bearings reduce wear, lower noise, and maintain consistent speed.

Driving & Control Mechanism

- Variable Speed Control via frequency inverter (VFD) to match upstream and downstream speeds.

- Soft Start/Stop to prevent product tipping.

- Clockwise or Counterclockwise Rotation to suit production layout.

Operational Process

- Product Entry – Items exit the packaging machine directly onto the table.

- Outward Flow by Design – Due to the concave-center and raised-edge profile, combined with centrifugal force from rotation, products naturally migrate outward, ensuring even distribution and preventing central pile-up.

- Buffering & Flow Control – Serves as temporary storage if downstream slows down.

- Easy Access for Operators – The outer edge positioning allows operators to grab products quickly for packing or inspection.

- Automation Integration – Robotic arms or conveyors can pick products directly from the outer ring for further processing.

Key Advantages of This Working Principle

- Natural Product Flow – Reduces manual adjustment.

- Continuous Production – Avoids bottlenecks between processes.

- Space Optimization – Circular motion maximizes reach in tight spaces.

- Product Protection – Smooth motion and gentle outward guidance prevent damage.

4. Typical Applications

The industrial rotary table is used far beyond just the end of a packaging line:

- Food & Beverage – Candy, biscuits, bottled drinks, canned foods.

- Pharmaceutical – Bottles, cartons, blister packs.

- Personal Care & Cosmetics – Shampoo, lotion, cosmetics packaging.

- Electronics & Small Hardware – Components before packing or assembly.

- Other Light Industries – Toys, stationery, small tools.

5. Integration with Other Packaging Equipment

The Lazy Susan Table is designed to connect seamlessly with a variety of upstream and downstream equipment:

- Vertical Form Fill Seal (VFFS) Machines – Collects bagged products.

- Flow Wrappers – Gathers wrapped products before secondary packing.

- Labeling Machines – Acts as a buffer after labeling for inspection.

- Checkweighers & Metal Detectors – Receives products after quality checks.

- Cartoning & Case Packing Machines – Provides accumulation before boxing.

- Filling Machines – Collects bottles/jars before capping or labeling.

- End-of-Line Palletizing Systems – Staging area before final shipment.

Benefit: This integration keeps production flowing, even when machine speeds differ.

6. You May Concerns & Our Solutions

| You May Concern | Fill Package Solution |

|---|---|

| Product pile-up or jamming | Profiled surface + variable speed + edge guides for fragile items. |

| Cleaning difficulty | Food-grade SUS304 + smooth finish + modular parts for easy cleaning. |

| Noise | Low-noise motor + precision bearings. |

| Load capacity | Reinforced frame + adjustable feet for stability. |

| Compatibility | Fully customized to match line height, speed, and layout. |

7. FAQ – Frequently Asked Questions

Q1: Can the Lazy Susan Table be customized in size?

Yes — diameter, height, and load capacity can all be tailored.

Q2: Is installation complicated?

No — mostly pre-assembled, requiring minimal setup.

Q3: What types of products is it suitable for?

Bottled, bagged, boxed, or irregularly shaped items.

Q4: How is the energy consumption?

Low, thanks to efficient motors and optimized transmission.

Q5: What about warranty and after-sales service?

Standard warranty + lifetime technical support.

8. Final Thoughts

The Lazy Susan Table — this modest yet powerful rotary packaging table — is a vital part of keeping packaging lines smooth and efficient.

With its profiled surface design, it naturally guides products outward, preventing pile-ups and making collection easier — a small change that delivers a big boost in efficiency.

If you’re looking for a stable, efficient, and hygienic solution for end-of-line accumulation, Fill Package can design it to fit your line perfectly.