VFFS Packaging Machine Timing Belt / Film Pulling Belt

Product Overview: The “Metronome” of Packaging Accuracy

Is Downtime from These Film Pulling Problems Costing Your Customers?

Problem 1: Inconsistent Bag Length and Photo-Eye Tracking Failures

Problem 2: Film Slipping During High-Speed Operation or with Heavy Films

Problem 3: Premature Belt Wear, Cracking, or Breaking

Problem 4: Belt Tracking Off and Severe Edge Wear

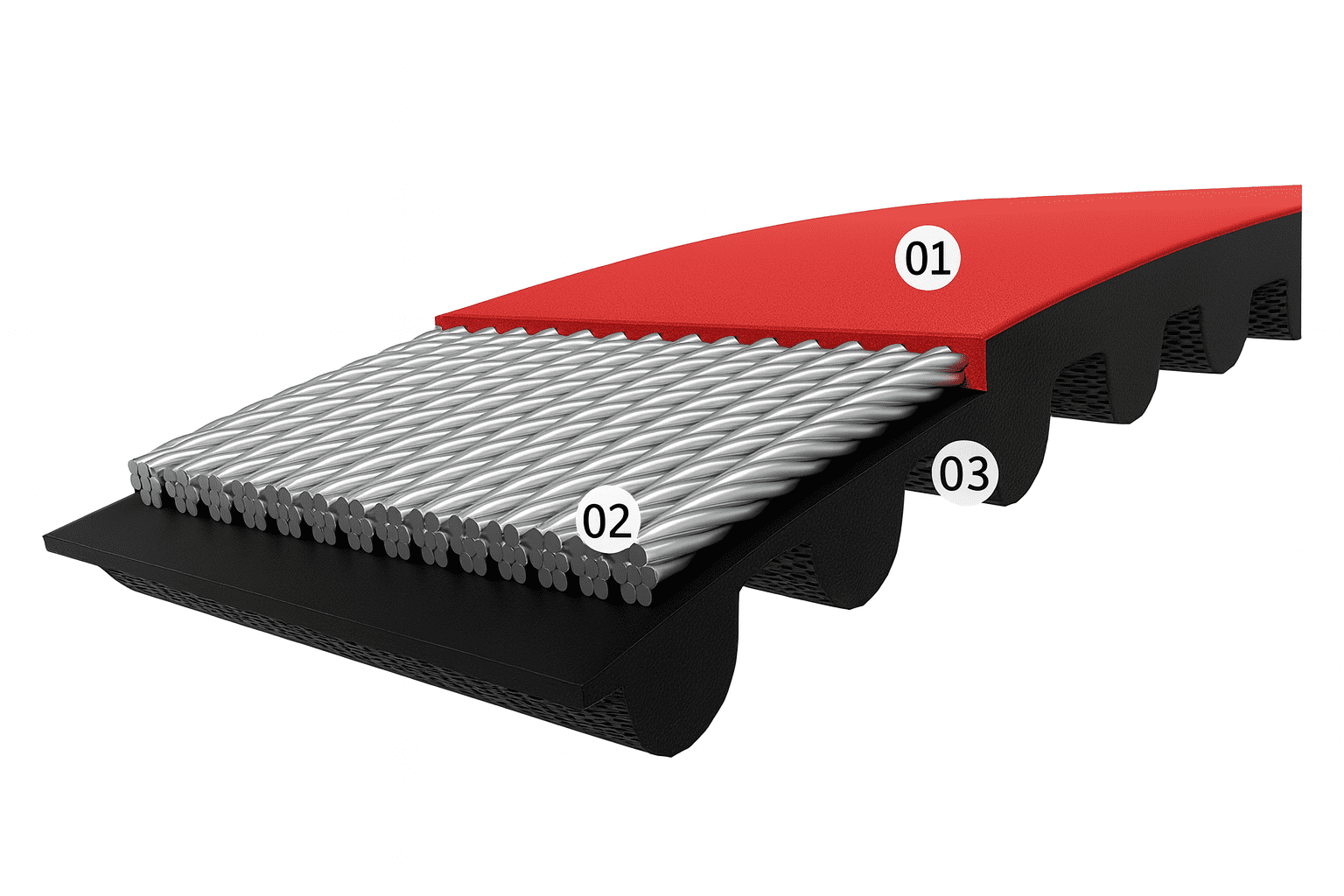

Anatomy of a High-Performance Timing Belt: Three-Layer Engineering

Understanding the internal structure of a timing belt helps explain why quality matters. Our belts feature a precision-engineered three-layer construction:

How to Select the Right Timing Belt: A Step-by-Step Guide

If you don’t know the specific model number of your belt, you can determine the correct replacement by following this systematic identification process:

- Rounded (HTD/Arc) Teeth: These feature a smooth, curved tooth profile that resembles a wave pattern. HTD (High Torque Drive) belts are the modern standard, offering smoother engagement, lower noise, and higher torque capacity.

- Trapezoidal Teeth: These have a more angular, trapezoid-shaped tooth profile. This is the traditional design, still widely used in many packaging machines, particularly older models.

- 5mm pitch (often designated as “5M” in HTD belts)

- 8mm pitch (often designated as “8M” in HTD belts)

- 10mm pitch (often designated as “T10” or “10mm” in trapezoidal belts)

- 12.7mm pitch (often designated as “L” in trapezoidal belts, as in “240L”)

Step 4: Measure the Circumference

- Match to a standard model: Compare your measurements to our specification table below

- Contact our technical team: Provide us with your measurements (tooth profile, tooth count, pitch, circumference, and width) for expert confirmation and recommendation

This systematic approach ensures you receive exactly the right belt for your application, eliminating the costly trial-and-error of ordering incorrect parts.

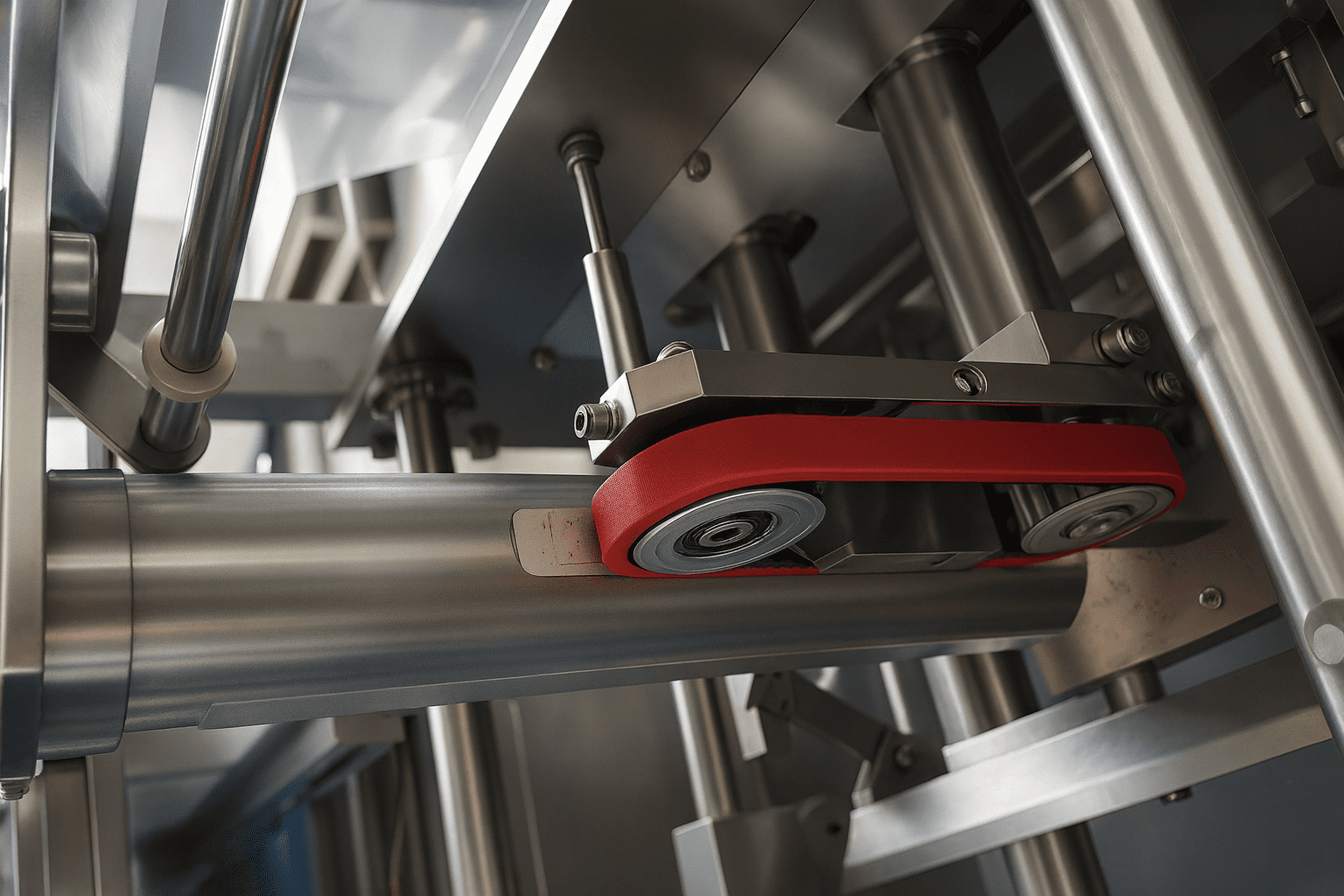

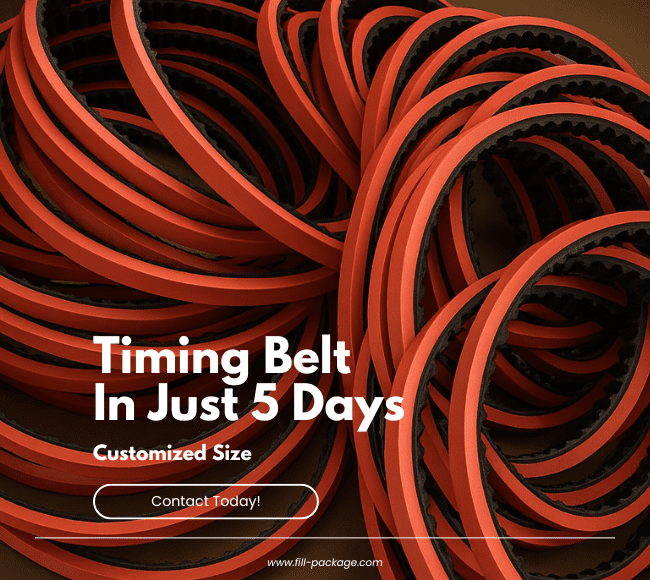

Material & Coating: Standard Black Rubber vs. High-Friction Red Coating

We offer two surface treatment options to meet different application requirements.

Our standard black timing belt is constructed from high-quality rubber or polyurethane (PU), offering cost-effectiveness and high versatility. This is the ideal choice for standard-weight, non-glossy packaging films where surface friction is adequate. We recommend this as the standard configuration to meet approximately 80% of typical packaging needs,

Quality Assurance & Certifications

Our timing belts are manufactured under strict quality control systems to ensure consistent performance and reliability.

- ISO 9001:2015 Quality Management System certified production facility

- Compliance with DIN 7721 and ISO 5296 international timing belt standards

- RoHS compliant materials for environmental responsibility

- 100% visual inspection of every belt before shipment

- Random sampling for tensile strength testing (exceeds ISO standards by 20%)

- Dimensional accuracy verified to ±0.5mm tolerance

- Accelerated aging tests simulate 5+ years of operational life

- FDA-compliant materials available for food packaging applications

- NSF-certified options for direct food contact (upon request)

Expected Service Life & Replacement Planning

- Standard Applications (8-10 hours/day, moderate speed): 12-18 months

- High-Duty Applications (16-20 hours/day, high speed): 8-12 months

- Light-Duty Applications (intermittent use, low speed): 18-24+ months

- Proper tension maintenance (most critical factor)

- Operating environment (temperature, humidity, contamination)

- Load characteristics (constant vs. shock loading)

- Maintenance frequency and quality

- Visible tooth wear or missing teeth

- Cracks in the belt body or along tooth roots

- Excessive elongation (belt no longer maintains proper tension)

- Fraying or delamination of the tooth fabric

- Frequent tracking adjustments required

Installation & Maintenance

Proper Installation

Keep Clean

Regular Inspection

Why Choose Our Timing Belts Over Competitors?

- Specification Guide: Covering Mainstream VFFS Machines

- Real-World Success Stories

- Simple Ordering Process

Model | Type | Circumference | Teeth | Width | Example Machine Compatibility |

240L | Trapezoidal | 640 mm | 64 | 17mm, 25mm | Songchuan ZL220, Ruiji Jinhong RL420 (for film width ≤ 420mm) |

255L | Trapezoidal | – | – | 17mm, 25mm | – |

270L | Trapezoidal | 685.8 mm | 72 | 17mm, 25mm | – |

T10-560 | Trapezoidal | 560 mm | 56 | 17mm, 25mm | T10 Series Machines |

T10-610 | Trapezoidal | 610 mm | 61 | 17mm, 25mm | – |

S8M-760 | HTD Round Tooth | 760 mm | 95 | 25mm | S8M Series High-Speed Machines |

- Determine your belt model or provide measurements (tooth profile, pitch, circumference, width)

- Specify quantity needed

- Indicate if red coating or custom width is required

- Contact us via email, phone, or website inquiry form

- Provide machine model or belt specifications

- Our team will respond within 4 business hours with pricing and availability

- Review and approve quotation

- Provide shipping address and payment terms

- For custom orders, we’ll provide a technical drawing for your approval

- Standard belts: Ship within 2-3 business days

- Custom belts: Production time 5-7 business days

- International shipping: 5-15 days depending on destination

- Tracking information provided upon shipment

- Installation guidance available if needed

- Quality issue? Contact us immediately for resolution

- Reorder? Your specifications are saved in our system for quick repeat orders

- T/T (Wire Transfer) – preferred for international orders

- Standard models: 1 piece (no MOQ)

- Custom specifications: 5 pieces minimum

Related Product

Our synchronous belts are manufactured to international standards. As long as the specifications (model, circumference, width, tooth profile) match, they are compatible with the vast majority of VFFS machine brands on the market, including but not limited to Songchuan, Ruiji Jinhong, Yamato, Mettler-Toledo, and more.

Yes. We offer custom cutting services for belt width. While standard widths are 17mm and 25mm, we can customize other widths to meet your needs.

Non-standard, custom-made timing belts typically require a production lead time of about one week. We recommend stocking a small quantity of your commonly used non-standard specifications.

HTD (High Torque Drive) belts feature rounded teeth that provide smoother engagement, lower noise, and higher torque capacity—they’re the modern standard. Trapezoidal teeth are the traditional design with angular profiles, still widely used in older machines. These two types are not interchangeable and require matching pulley profiles.

Replace your belt when you observe visible tooth wear, cracks in the belt body, excessive elongation, fraying of the tooth fabric, or when frequent tracking adjustments are required. Implementing a preventive replacement schedule based on operating hours (typically 12-18 months for standard applications) is recommended.