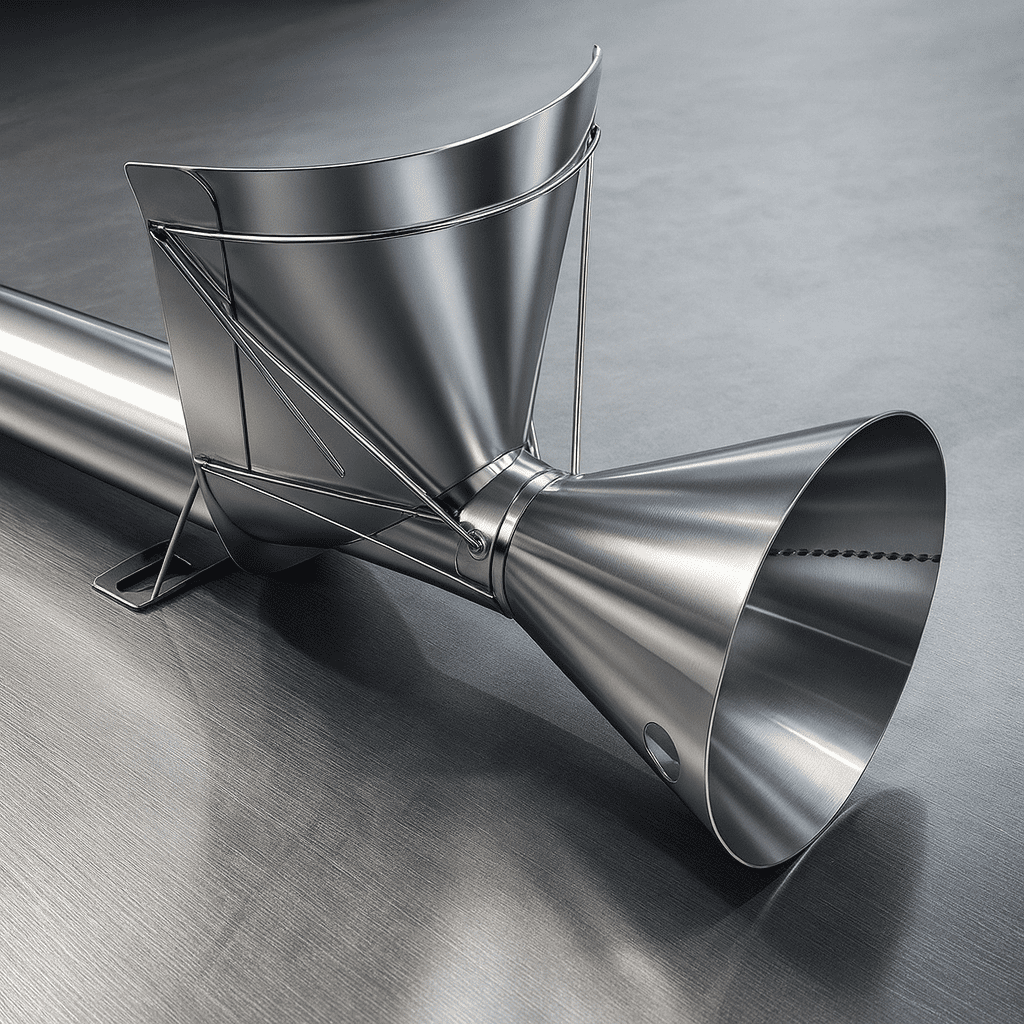

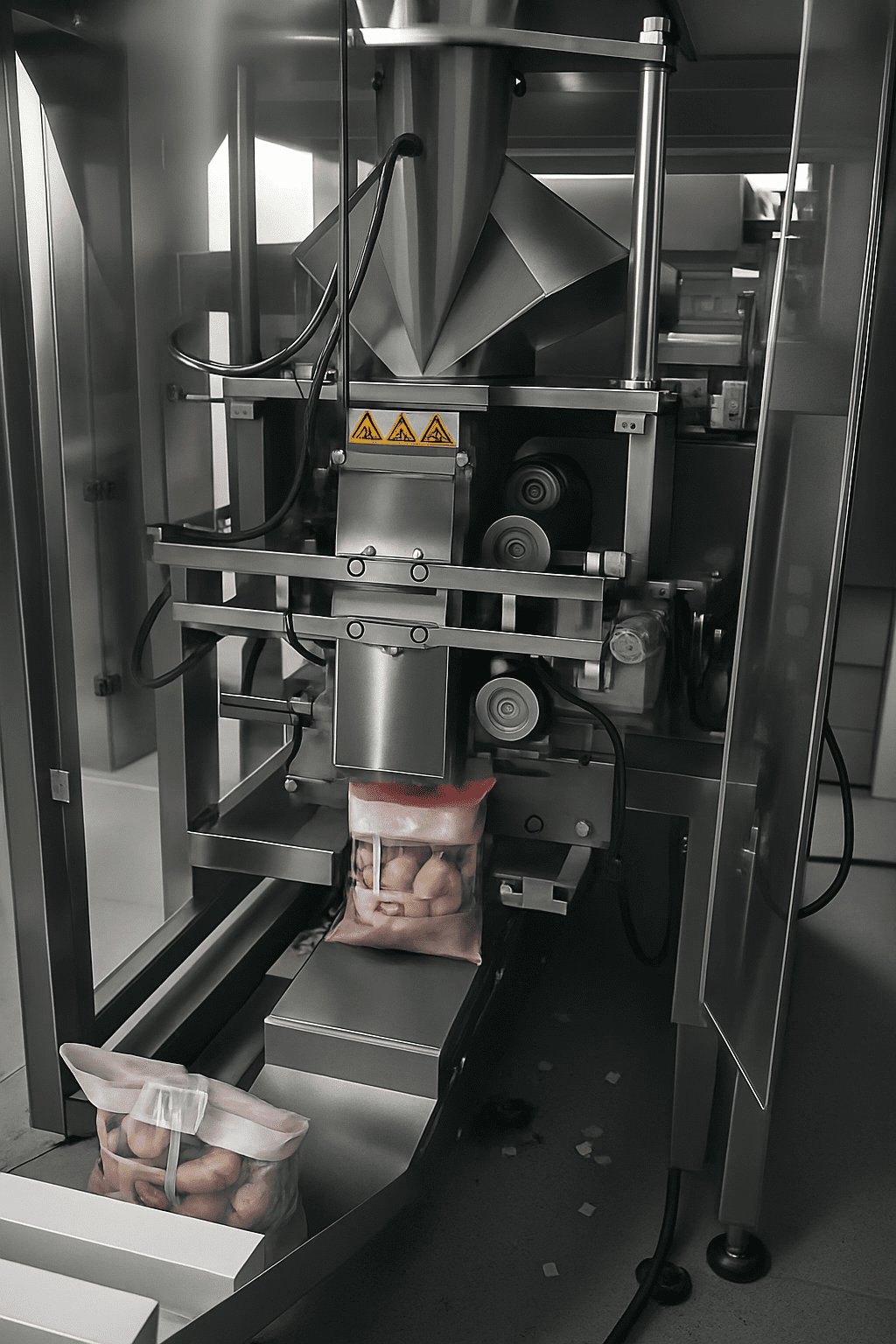

In the complex ecosystem of a Vertical Form Fill and Seal (VFFS) machine, every component plays a critical role. However, few are as fundamental as the bag former, also known as the forming shoulder or forming collar. This masterfully shaped piece of stainless steel is the heart of the packaging process, responsible for transforming a flat web of packaging film into a perfectly formed tube, ready for filling and sealing.

For machine manufacturers, a well-designed former is key to achieving high speeds and consistent bag quality. Meanwhile, parts wholesalers recognize it as a high-value replacement part with constant demand. Additionally, for food factories, understanding the former is the first step to solving a host of common packaging problems.

This in-depth guide covers everything you need to know about VFFS bag formers, from their core function and performance features to selection criteria, replacement timing, and emerging technologies.

How Does a Bag Former Work?

The function of a bag former is elegant in its simplicity. First, a flat roll of packaging film is fed over the top “wing” or “collar” of the former. Then, the unique, complex geometry of the former guides the film, causing it to wrap around the cylindrical “forming tube.” As the film is pulled down by the machine’s pulling belts, the two outer edges of the film overlap, creating a “lap” or “fin” that is then sealed by the vertical sealer to create a continuous tube. Finally, the product is dropped through the forming tube into the newly formed bag.

The Anatomy of a High-Performance Former

While they may look like simple, polished metal, high-performance formers are the result of advanced engineering and precision craftsmanship. Several key features determine a former’s quality and performance.

1. Material and Surface Finish

The choice of material directly impacts the former’s durability, hygiene compliance, and resistance to harsh production environments. 304 Stainless Steel is the industry standard due to its excellent formability, corrosion resistance, and cost-effectiveness. In contrast, for applications involving highly acidic products, aggressive washdown chemicals, or marine environments, 316 Stainless Steel is the superior choice, offering enhanced resistance to pitting and corrosion.

The surface finish is equally critical. Specifically, a flawless, mirror-like polish minimizes friction, allowing the film to glide smoothly over the former. Any scratches, dents, or poor welds will increase friction, causing the film to drag, wrinkle, or tear. Alternatively, for applications involving sticky films (such as those used for confectionery) or dusty products (like powdered spices), a dimpled or textured surface can be strategically employed to reduce surface contact area and minimize friction-related issues.

2. The “Wing” or Collar Design

The shape of the collar is the most critical design element. It dictates how gently and evenly the film is handled as it transitions from a flat web to a formed tube. Consequently, a poorly designed wing will put uneven stress on the film, leading to tracking issues, wrinkling, and potential breakage at high speeds. Advanced former designs use computational fluid dynamics (CFD) modeling to optimize the wing geometry for minimal film stress.

3. Forming Angle

The angle of the forming tube relative to the horizontal plane is an often-overlooked but important parameter. For instance, a steeper angle (more vertical) is suitable for fast-moving, free-flowing products like granules or pellets, as gravity assists in rapid product descent. On the other hand, a shallower angle is better for slower-moving, cohesive powders that need more time to settle and de-aerate before sealing.

4. Build Quality

Precision manufacturing is non-negotiable. Look for seamless welds, perfectly rounded edges, and consistent wall thickness. Indeed, any sharp corners, rough weld seams, or dimensional inconsistencies will snag the film, causing immediate operational problems and accelerated wear.

When Should You Replace Your Bag Former? 5 Critical Signals

A bag former is a wear part. Over millions of cycles, the constant friction of the film will eventually wear down its surface. Therefore, recognizing the signs of a failing former and replacing it proactively prevents costly downtime, reduces material waste, and maintains product quality. Here are the five critical signals that indicate it’s time for a replacement.

Signal 1: Obvious Performance Degradation

Performance issues are often the first and most visible signs of a worn former. If you observe any of the following, your former is likely the culprit.

Film Tracking Becomes Unstable

The film consistently drifts to one side, and no amount of adjustment to the film tension or guide rollers can stabilize it. This indicates that the former’s guiding surfaces are no longer symmetrical due to uneven wear.

Vertical Seal Alignment Deteriorates

The overlap of the film edges at the vertical sealer is inconsistent, leading to weak seals or channel leaks. This is often caused by a worn or damaged edge on the former that is creating a crease or fold in the film.

Reject Rate Climbs Above Acceptable Levels

If your bag reject rate climbs above 0.5% (when a well-maintained system should be below 0.2%), and the root cause analysis points to seal failures or bag deformities, the former is a prime suspect.

Signal 2: Physical Wear Indicators

Regular visual and tactile inspections of the former can reveal physical damage before it leads to catastrophic failure.

Surface Damage Is Visible

Run your hand (or a soft cloth) over the entire film path on the former. Any roughness you can feel will cause friction and film damage. Even minor scratches can act as stress concentrators, leading to film tears.

Guiding Edges Show Wear

The edges of the former that guide the film into the tube are particularly susceptible to wear. If these edges are no longer sharp and well-defined, the film will not be guided accurately, leading to tracking and sealing problems.

Corrosion Appears

While stainless steel is corrosion-resistant, it is not corrosion-proof. If you observe any rust, pitting, or discoloration (especially in non-food-contact areas or at weld points), the structural integrity of the former may be compromised.

Signal 3: Production Requirement Changes

Sometimes, a former replacement is driven not by wear, but by evolving business needs.

Your Product Line Expands

You are introducing new products that require a different bag size, shape (e.g., switching from pillow bags to gusseted bags), or film type. Consequently, your existing former is simply not compatible with the new requirements.

Packaging Material Changes

You are switching to a new film supplier or a different film structure (e.g., from a traditional laminate to a biodegradable material). As a result, the new film does not run well on your current former due to differences in stiffness, friction, or heat sensitivity.

Speed Targets Increase

You are investing in upgrading your machine to run at higher speeds (e.g., from 60 to 80 bags per minute). Unfortunately, your current former’s design has become the bottleneck, unable to handle the film at the new, faster rates without causing issues.

Signal 4: Maintenance Cost Analysis

A purely financial analysis can also justify a former replacement.

Annual Maintenance Costs Are Excessive

If the cumulative cost of repairing, polishing, or working around issues with the former exceeds 15% of the cost of a new former in a single year, replacement is the more economical choice.

Downtime Exceeds Acceptable Limits

If former-related issues are causing more than 8 hours of unplanned downtime per month, the lost production value far outweighs the cost of a new part.

Parts Are Obsolete

The original manufacturer has discontinued your machine model, and replacement parts (or the expertise to repair the former) are no longer readily available.

Signal 5: Hygiene and Compliance Concerns

In the food and pharmaceutical industries, hygiene is paramount. If your former has developed crevices, pits, or rough areas where product residue or bacteria can accumulate and cannot be effectively cleaned, it must be replaced immediately to maintain compliance with food safety regulations.

A Comprehensive 5-Step Guide to Selecting the Right Former

Choosing the correct former is a multi-faceted decision that requires careful analysis of your production requirements, equipment, and materials. Follow this systematic approach to ensure you select the optimal forming solution.

Step 1: Define Your Production Requirements

Begin by thoroughly analyzing what you are packaging and how you are packaging it.

Analyze Product Characteristics

Is your product a free-flowing powder, a cohesive granule, a viscous liquid, or a fragile solid? The product’s flow characteristics will influence the required forming angle and tube diameter. For example, a sticky product may require a larger-diameter tube to prevent bridging, while a free-flowing product can use a narrower tube for faster throughput.

Determine Packaging Material Specifications

What type of film are you using? Is it a polyethylene (PE) monolayer, a multi-layer laminate, or a newer biodegradable material? Additionally, what is the film’s thickness (measured in microns or gauge), and what is its coefficient of friction? Films with a high coefficient of friction (sticky films) may require a former with a specialized low-friction coating or a textured surface.

Define Production Parameters

What is your target production speed (bags per minute)? What are the exact dimensions of the bags you need to produce (length, width, gusset depth if applicable)? Furthermore, how many hours per day will the machine be running? High-speed, high-volume operations require formers built to tighter tolerances and from more durable materials.

Step 2: Equipment Compatibility Check

A former must be physically and functionally compatible with your existing VFFS machine.

Verify Interface Dimensions and Mounting Pattern

Different machine manufacturers use different mounting systems. Therefore, you must provide the exact make and model of your VFFS machine (e.g., “Ishida Atlas 5000,” “Rovema VPK 260”) to ensure the new former has the correct bolt hole pattern, mounting flange dimensions, and overall height.

Confirm Control System Compatibility

Is your machine mechanically driven (cam-based) or servo-driven? While the former itself is a passive component, the machine’s control system dictates the timing and speed at which the film is pulled, which can affect the former design.

Assess Installation Space Constraints

Measure the available vertical and horizontal space around the forming area. Some high-performance formers have larger wings or require additional clearance for film threading.

Step 3: Material and Process Selection

The material and surface treatment of the former should be matched to your specific application environment.

Food Industry Standard

For direct food contact applications, 316 Stainless Steel with a mirror polish (Ra < 0.4 µm) is the gold standard. This ensures compliance with FDA and EU food safety regulations and provides a surface that is easy to clean and sanitize.

Corrosive Environments

If you are packaging acidic products (like vinegar or citrus), or if your production area uses aggressive cleaning chemicals, consider a former with a Teflon (PTFE) coating or one made from a specialized corrosion-resistant alloy.

High-Wear Applications

For abrasive products or extremely high-speed operations, look for formers with hardened edges or replaceable wear strips on the most critical contact points. This can significantly extend the former’s service life.

Step 4: Supplier Evaluation Criteria

Not all former suppliers are created equal. Evaluate potential suppliers based on these critical factors.

Technical Support and Responsiveness

Does the supplier have experienced application engineers who can help you select the right former and troubleshoot issues? Moreover, what is their typical response time for technical inquiries?

Customization Capabilities and Lead Time

Can they design and manufacture a custom former to your exact specifications if a standard model doesn’t fit? What is their lead time for custom orders versus stock items?

Industry Reputation and References

Ask for case studies or references from customers in your specific industry (food, pharmaceutical, chemical, etc.). A supplier with a proven track record in your sector is invaluable.

Step 5: Total Cost of Ownership (TCO) Analysis

Don’t just look at the purchase price. Instead, consider the total cost of ownership over the former’s expected lifespan (typically 3-5 years in a high-volume operation):

- Initial Purchase Price

- Installation and Commissioning Costs

- Expected Maintenance Costs (cleaning, minor repairs)

- Downtime Costs (if the former is prone to causing issues)

- Film Waste Costs (a poorly designed former can increase scrap rates)

Ultimately, a slightly more expensive, higher-quality former that reduces downtime and waste will often have a lower TCO than a cheap alternative.

Troubleshooting Common Issues Linked to the Bag Former

Problem | Potential Former-Related Cause | Solution |

Film Wrinkling | Damaged or scratched former surface creating friction; Incorrect wing design for the film’s stiffness. | Inspect the former for any surface damage using a bright light and your fingertips. If the former is new, the wing geometry may be poorly designed for your film; contact the supplier for a redesign or replacement. |

Poor Film Tracking | The former is not mounted centrally to the machine’s centerline, or the former itself is asymmetrical due to poor manufacturing tolerances. | Use a plumb line or laser alignment tool to check that the former is perfectly centered. If the problem persists after alignment, the former itself may be defective and should be returned. |

Vertical Seal Leaks (Channel Leaks) | A sharp edge, burr, or dent on the forming tube is creasing the film just before it enters the vertical sealing section, creating a pathway for leakage. | Carefully inspect the entire path the film travels over the former, paying special attention to the area immediately before the vertical seal jaws. Use fine-grit sandpaper or a polishing compound to smooth out any imperfections. |

Product Bridging in Tube | The forming tube diameter is too small for the product’s particle size or flow characteristics. | Replace with a former that has a larger internal diameter. Consult with the former supplier to determine the optimal tube size for your product. |

Maintenance Best Practices for Maximum Former Lifespan

Proper care and handling can significantly extend the life of your bag former and maintain optimal performance.

Clean with Care

Never use abrasive pads, metal scrapers, or harsh chemicals (like bleach or strong acids) to clean a former. These will damage the polished surface. Instead, use a soft, lint-free cloth with isopropyl alcohol or a mild, pH-neutral detergent. For stubborn residue, soak the former in warm, soapy water before gently wiping it clean.

Handle with Extreme Caution

Formers are precision instruments and are easily damaged by impact. During changeovers, never place them directly on a concrete floor or bang them against the machine frame. Always store formers on a dedicated, padded rack or in protective foam-lined cases.

Regular Inspection Schedule

Make a visual and tactile inspection of the former’s surface a part of your daily or weekly preventive maintenance checklist. Catching a minor scratch early can prevent it from becoming a major problem.

Proper Installation Torque

When installing a former, always use a calibrated torque wrench and follow the manufacturer’s specified torque values for the mounting bolts. Over-tightening can warp the former, while under-tightening can allow it to shift during operation.

Innovation and Future Trends in Bag Former Technology

The VFFS industry is not standing still. Emerging technologies are transforming the humble bag former from a passive component into an intelligent, adaptive system.

Smart Former Technology

The next generation of formers is being equipped with integrated sensors and connectivity.

Real-Time Monitoring

Embedded sensors can continuously monitor film tension, position, and temperature as the film travels over the former. This data is fed back to the machine’s control system or a cloud-based analytics platform.

Self-Compensating Systems

Advanced formers can use micro-actuators to automatically adjust the wing position or forming angle in real-time to compensate for film variations or wear. As a result, they maintain optimal performance without operator intervention.

IoT Connectivity and Predictive Maintenance

By connecting the former to the Industrial Internet of Things (IoT), manufacturers can implement predictive maintenance strategies. The system can alert operators when sensor data indicates that the former is beginning to wear and will need replacement soon. Consequently, this allows for planned downtime rather than unexpected failures.

Multi-Functional and Quick-Changeover Designs

Flexibility is becoming increasingly important in modern packaging operations.

One Former, Multiple Bag Styles

Innovative designs are emerging that allow a single former to produce multiple bag types (e.g., pillow bags and gusseted bags) by using modular, interchangeable components or adjustable geometry.

Rapid Changeover Systems

Tool-less, quick-release mounting systems are reducing the time required to swap out a former from 30-60 minutes down to just 5-10 minutes. Therefore, this minimizes production interruptions when switching between products.

Compatibility with Sustainable Materials

As the industry shifts toward biodegradable and compostable films, former manufacturers are developing new surface treatments and geometries optimized for these materials. These new films often have different friction and stiffness characteristics compared to traditional plastics.

Conclusion: Your Partner for Perfect Packaging

The bag former is more than just a component; it is the foundation of a quality package. A well-designed, properly maintained former ensures efficient production, reduces waste, and delivers a product that reflects the quality of the brand within.

Understanding when to replace your former, how to select the right one for your application, and how to maintain it properly are critical skills for any packaging operation. As technology advances, the formers of tomorrow will be smarter, more adaptable, and more efficient than ever before.

Whether you are a machine builder looking for a reliable partner, a wholesaler stocking high-demand parts, or a food factory in need of a replacement, Fill-Package offers a comprehensive range of high-performance VFFS bag formers. Contact us today to discuss your requirements and let our experts guide you to the perfect forming solution.