In the world of industrial machinery, particularly in the fast-paced packaging sector, every component matters. Yet, few are as universally present—and as frequently underestimated—as the machine handle. From the access door on a VFFS machine to the control cabinet on a conveyor line, handles are the primary interface between operator and equipment.

For machine manufacturers, selecting the right handle is about more than just functionality; it’s about safety, ergonomics, and the professional appearance that defines your brand. For parts wholesalers, understanding which handles are in highest demand and why is the key to building a profitable, fast-moving inventory.

This guide will explore the essential types, materials, and applications of machine handles, with a laser focus on the two materials that dominate the packaging industry: aluminum alloy and plastic (nylon).

Why Aluminum and Plastic Dominate the Packaging Industry

While stainless steel handles have their place in specialized food-contact applications, the reality is that aluminum alloy and plastic handles are the workhorses of the packaging machinery sector. Here’s why:

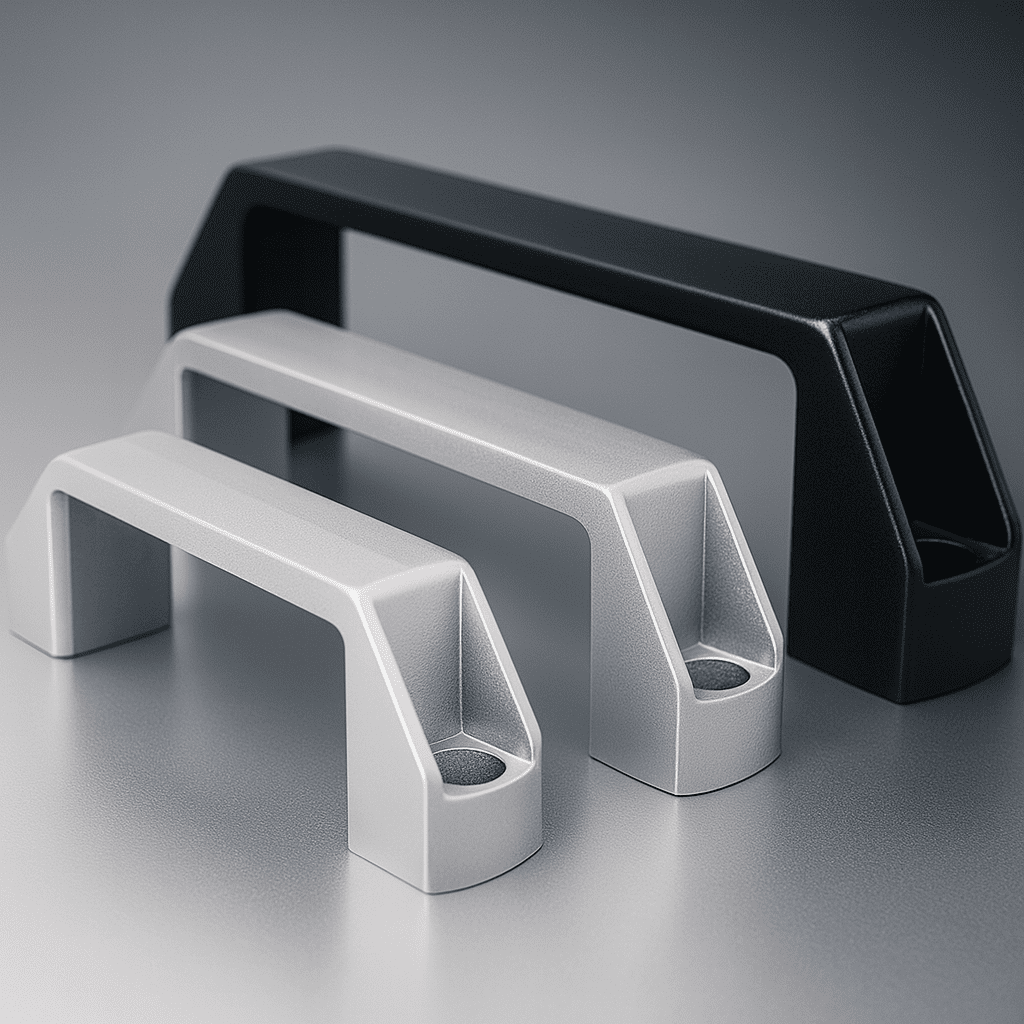

Aluminum/Zinc Alloy Handles: The Premium Standard

Aluminum strikes the perfect balance between strength, weight, and aesthetics. In packaging machinery, where equipment is frequently moved, adjusted, or reconfigured, the lightweight nature of aluminum is a significant advantage. Additionally, when anodized, aluminum offers excellent corrosion resistance and a sleek, modern appearance that elevates the machine’s overall design.

Key Benefits:

- Lightweight yet strong

- Corrosion-resistant (when anodized)

- Professional, modern aesthetic

- Excellent for frequently adjusted components

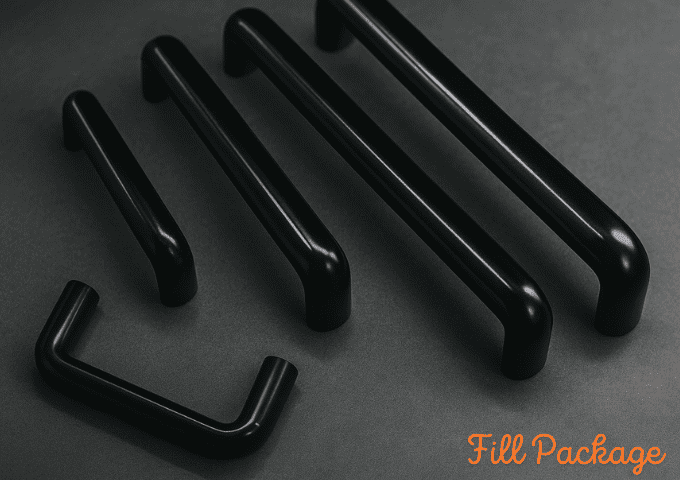

Plastic (Nylon) Handles: The Versatile Workhorse

Plastic handles, particularly those made from high-quality nylon or reinforced polymers, are the go-to choice for a wide range of applications. They are cost-effective, electrically non-conductive (critical for electrical cabinets), and resistant to many chemicals. Furthermore, they do not require any surface treatment and are available in a variety of colors to match machine branding.

Key Benefits:

- Excellent electrical insulation

- Cost-effective

- Chemical resistant

- Lightweight

- No surface treatment required

The Four-Fold Value of a High-Quality Machine Handle

Why should a machine builder care about the specifics of a handle? Because a well-chosen handle delivers value in four distinct ways:

- Operational Safety: A handle with a secure, non-slip grip ensures that operators can open heavy access panels or apply necessary force without their hand slipping, which is a common cause of minor injuries.

- Ergonomics and Efficiency: A handle that is properly sized and shaped for the human hand reduces operator fatigue, especially for tasks that require frequent interaction, like opening and closing guarding doors during changeovers. This translates to faster, more efficient operation.

- Durability and Reliability: Industrial environments are harsh. A quality handle made from appropriate materials will resist impacts, maintain its integrity over millions of cycles, and reduce the need for replacement.

- Professional Aesthetics: A sleek, robust, and well-integrated handle contributes significantly to the machine’s overall appearance. It conveys a sense of quality and thoughtful design to the end-user, enhancing your brand’s reputation.

A Guide to Machine Handle Types

While there are countless designs, most industrial handles fall into a few key categories:

1. Pull Handles (Bridge Handles)

This is the most common type, featuring a bar-like grip connected to the surface at two points. They are versatile and can be used for pulling, pushing, and lifting. Their simple, robust design makes them suitable for almost any application. Aluminum pull handles are particularly popular for access doors and panels.

2. Folding or Recessed Handles

These handles are designed to sit flush with the machine surface when not in use. They are ideal for applications where a protruding handle could be a snagging hazard or in applications where space is extremely limited. Plastic folding handles are a cost-effective choice for this category.

3. Star Knobs and Adjustment Handles

These are specialized handles designed for frequent adjustment. They typically have a star-shaped or knurled grip for easy turning by hand, often used for tensioning, height adjustment, or locking mechanisms. Plastic star knobs are lightweight and comfortable for repeated use.

4. Tubular Handles

Made from hollow aluminum tubing, these handles offer an excellent strength-to-weight ratio. They are often used for longer-span applications, such as the full-width handle on a large access door.

Material Selection: Matching the Handle to the Application

Material | Key Characteristics | Best For | Typical Applications in Packaging |

Aluminum Alloy | Lightweight, strong, corrosion-resistant (anodized), modern aesthetic. | Access doors, adjustment modules, frequently moved components. | VFFS access panels, conveyor guard rails, film roll handling. |

Plastic/Nylon | Excellent electrical insulation, cost-effective, chemical resistant, lightweight. | Electrical cabinets (critical!), control panels, non-load-bearing applications. | Control cabinet doors, electrical enclosures, drawer pulls. |

Stainless Steel (SUS304) | Excellent corrosion resistance, high strength, food-safe. | Specialized food-contact areas, washdown environments. | Hygienic access panels on VFFS in direct product zones (less common). |

Detailed Applications in Packaging Machinery

Let’s explore where these handles are put to work across a typical packaging line, with specific selection guidance for each application.

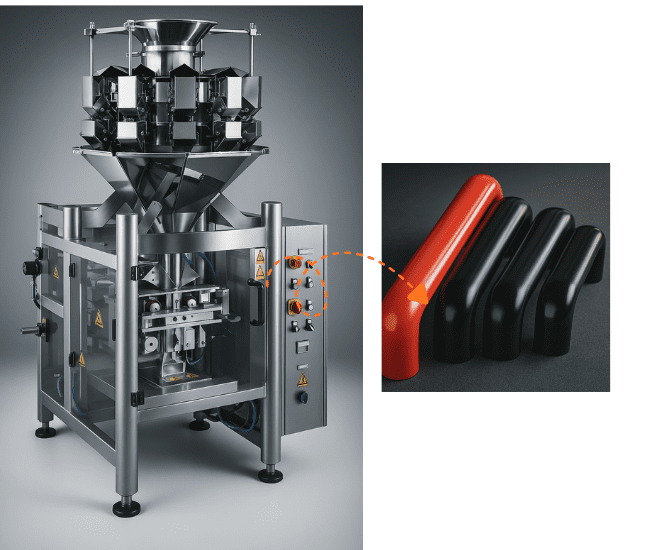

1. Vertical Form Fill and Seal (VFFS) Machines

Application Points:

- Forming Tube Adjustment Module: Handles for adjusting the position or angle of the forming tube.

- Film Roll Change Handles: Grips for maneuvering heavy film rolls into position.

- Access Doors and Inspection Windows: Handles for opening panels to access sealing jaws, cutters, and product feed areas.

Selection Guidance:

- Frequently Adjusted Parts: Use plastic star knobs or adjustment handles for easy, tool-free operation.

- Hygienic Zones: Use stainless steel curved pull handles for areas in direct contact with the product.

- Main Access Doors: Use large aluminum folding handles or pull handles for quick, easy opening and closing.

2. Conveyor Lines and Conveyor Systems

Application Points:

- Tensioning Mechanism Adjustment Handles: For adjusting belt tension.

- Guard Rail and Side Panel Handles: For opening protective panels.

- Modular Unit Handling Grips: For lifting and positioning modular conveyor sections.

Selection Guidance:

- Adjustment Points: Use handles with graduated markings or lockable positions for precise, repeatable settings.

- Heavy-Duty Modules: Use aluminum tubular handles with a metal core for strength.

- Impact-Prone Areas: Use handles made from impact-resistant nylon or reinforced plastic.

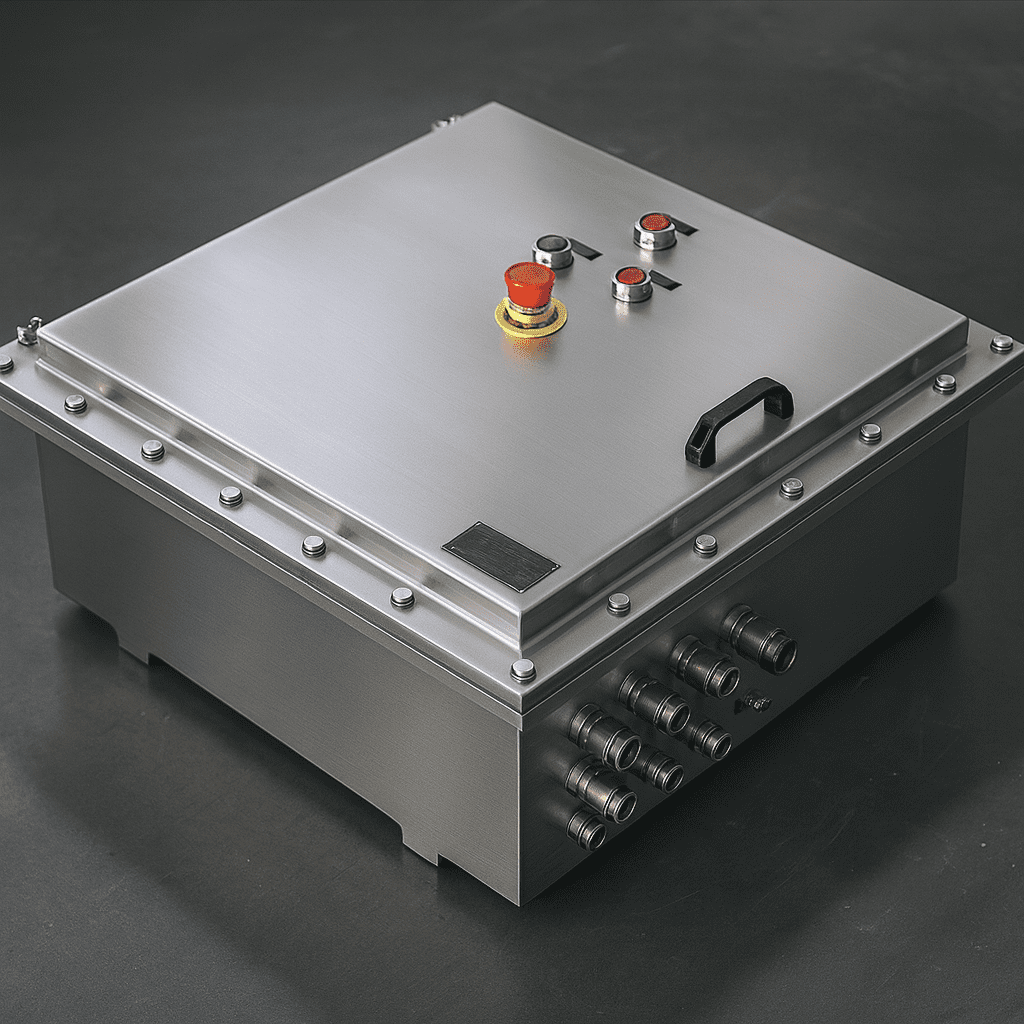

3. Electrical Cabinets and Control Panels (CRITICAL APPLICATION!)

Application Points:

- Cabinet Door Opening Handles: The primary access point for electrical maintenance.

- Drawer Pulls: For sliding out control modules or terminal blocks.

- Emergency Disconnect Lockable Handles: For energy isolation during maintenance.

Selection Guidance:

- Insulation is Mandatory: Plastic (nylon) handles are the standard choice due to their excellent electrical insulation properties, protecting technicians from accidental contact with live components.

- Outdoor Cabinets: Select handles with a high IP rating (Ingress Protection) and corrosion-resistant materials. Even for plastic, ensure UV resistance.

- Safety Lockable Handles: These are essential for implementing Lockout/Tagout (LOTO) procedures to ensure energy isolation.

- Professional Appearance: The handle is often the most visible component on a control cabinet. Choose a clean, professional design that reflects the quality of the equipment inside.

4. Extended Applications Across the Packaging Line

- Flow Wrappers (HFFS): Adjustment and locking handles for the horizontal sealing and cutting knife mechanisms. Aluminum adjustment knobs are ideal.

- Palletizing Robots: Handles on safety fence gates. Plastic pull handles are cost-effective and safe.

- Filling and Capping Machines: Hand wheels and handles for height adjustment mechanisms. Aluminum hand wheels provide a premium feel.

- Entire Production Line: Any protective cover, door, or movable module that requires manual intervention benefits from a well-chosen handle.

For Parts Wholesalers: Building a Profitable Handle Inventory

If you supply components to machine builders or end-users, here’s how to build a smart, fast-moving inventory of machine handles:

1. Understand Your Customer’s Industry

The needs of a food processor, a chemical plant, and a logistics warehouse are vastly different. Food processors prioritize hygiene (stainless steel or easy-to-clean plastic), while electronics manufacturers prioritize anti-static properties.

2. Stock the “Best Sellers”

Focus your inventory on the most universally applicable models:

Universal Types:

- Standard hole-spacing nylon folding handles (e.g., 96mm, 128mm center-to-center)

- Aluminum pull handles in common lengths (100mm, 150mm, 200mm)

- Plastic star knobs in M8 and M10 thread sizes

Industry-Specific Types:

- Food-grade stainless steel handles for food processing clients

- High IP-rated lockable handles for outdoor electrical cabinets

3. Offer Solutions, Not Just Products

Don’t just sell a handle. Offer a complete solution: handle + lock + hinge kits for common applications like electrical cabinet doors. This adds value and increases your average order size.

4. Focus on Quality and Certifications

Stock handles from suppliers who can provide authoritative test reports, such as:

- Load capacity testing

- Salt spray corrosion testing (for outdoor applications)

- IP rating certifications (for electrical enclosures)

Building a reputation for quality will earn you repeat customers and referrals.

Conclusion: The Small Component with Big Impact

Machine handles are a perfect example of how small details can have a big impact. For manufacturers, they are an opportunity to enhance safety, improve user experience, and reinforce the quality of your brand. For parts wholesalers, they are a consistent, high-demand product category with clear selection criteria.

By understanding that aluminum and plastic handles are the true workhorses of the packaging industry, and by focusing on the critical application of electrical cabinets, you can make smarter purchasing decisions, build better machines, and serve your customers more effectively.

Ready to source high-quality aluminum and plastic machine handles for your packaging equipment? Contact us today to explore our extensive range and find the perfect fit for your application.