In today’s fast-paced manufacturing environment, industries such as food, pharmaceuticals, and cosmetics face significant challenges in sachet packaging operations. Rising labor costs, increasing demands for production efficiency, and stringent quality standards are pushing businesses toward intelligent and automated solutions. Among these, the Automatic Sachet Counting Machine—also known as the Sachet Sorting Counting Machine—has emerged as a critical component in modern packaging lines. This article explores how these machines address production bottlenecks, improve efficiency, and deliver long-term value through advanced after-sales support.

Challenges in Traditional Sachet Handling and Counting

Escalating Labor Costs

Manual sorting and counting of sachets are labor-intensive and costly. Workers must arrange and feed sachets into downstream packaging equipment, a process that consumes valuable time and resources. Annual labor costs for manual sachet handling in a single production line can run into tens of thousands of dollars, with rising wages adding further strain.

Inefficiency and Production Bottlenecks

Manual handling often caps speeds at 20–30 sachets per minute, far below the capabilities of modern downstream packaging equipment. This mismatch creates a bottleneck, slowing overall production output and reducing profitability. Fluctuations in manual performance also lead to uneven production flow.

Inconsistent Quality and Accuracy

Human error introduces inconsistencies in counting and arrangement, which can result in underfilled or overfilled packages, misaligned sachets, or hygiene risks—particularly critical in food and pharmaceutical sectors. Such errors can damage brand reputation and lead to customer complaints.

The Automatic Sachet Counting Machine: Transforming Efficiency

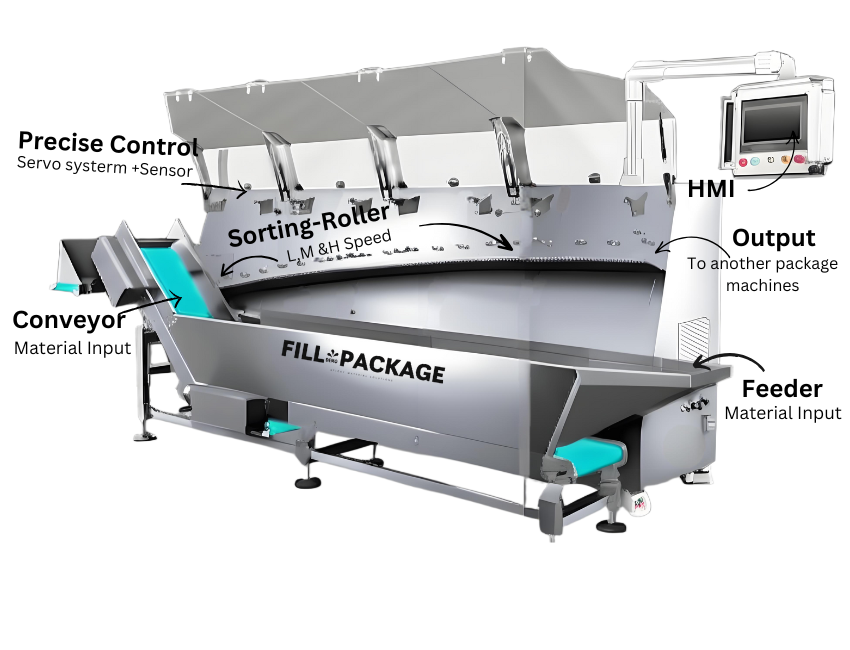

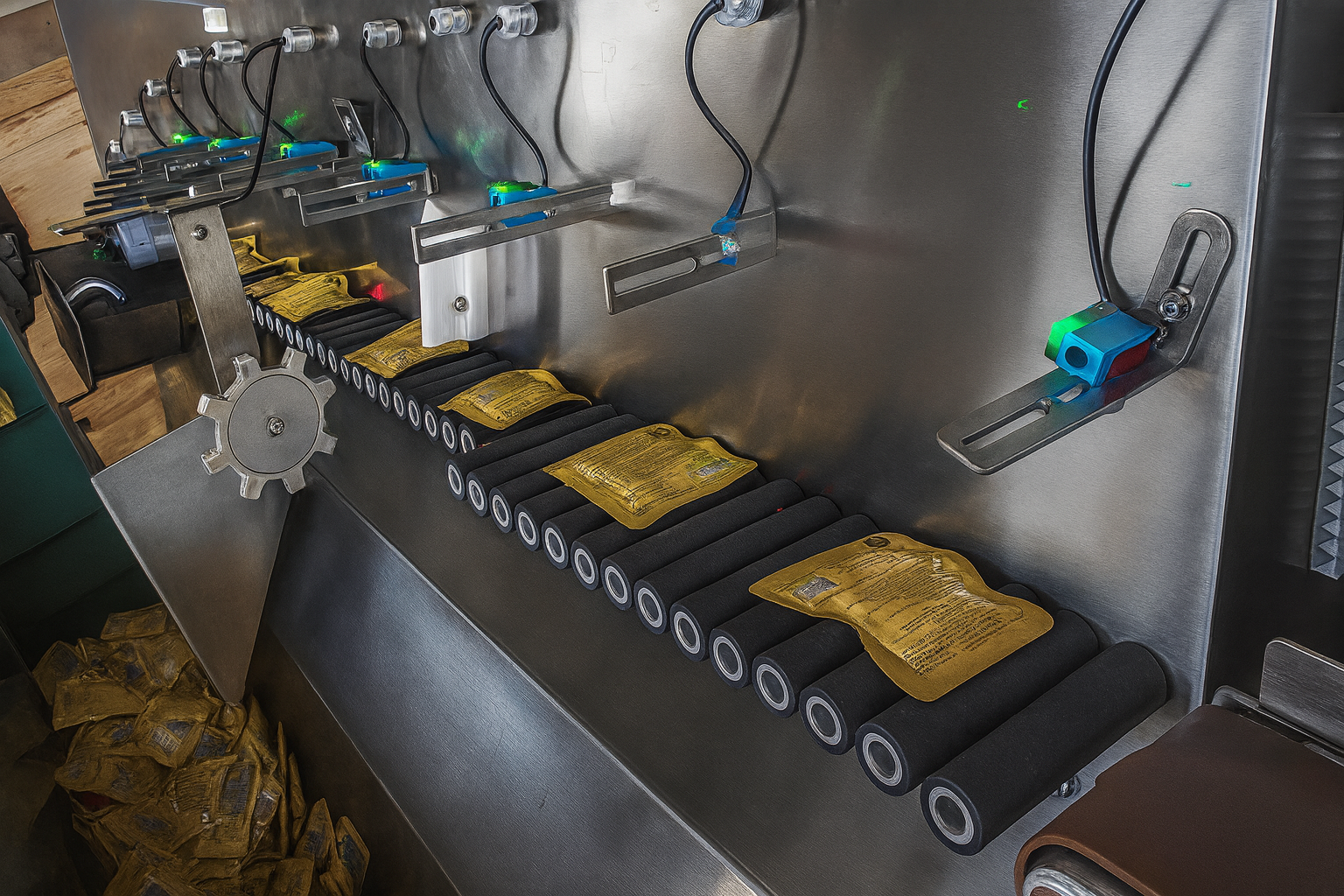

The Automatic Sachet Counting Machine replaces slow, error-prone manual processes with high-speed, precision-controlled automation. Using advanced mechanical design, servo-driven rollers, and optical sensors, it organizes, counts, and feeds sachets directly into packaging lines with minimal human intervention.

High-Speed Performance

Depending on the model, these machines can achieve speeds of 80–300 sachets per minute, increasing output by up to 10 times compared to manual methods. For example, a high-end FL20-3200 can process 180–300 sachets/min, making it ideal for high-volume operations.

Versatility Across Product Sizes

Through adjustable or interchangeable rollers (ranging from φ12mm to φ29mm), the same machine can handle sachets between 84–290mm in length, accommodating diverse product lines without the need for separate equipment.

Precision Counting and Arrangement

Equipped with servo control systems and photoelectric sensors, these machines ensure consistent accuracy. Real-time feedback allows the system to adjust automatically to maintain perfect counts and spacing, virtually eliminating counting errors.

Low-Noise, Hygienic Operation

With noise levels under 70dB and designs optimized for cleanliness (including fingerprint-resistant coating), these machines are ideal for sensitive sectors such as pharmaceuticals, nutraceuticals, and food production.

Key Business Benefits

Dramatic Labor Cost Savings

Replacing multiple workers with one machine operator can reduce labor costs by 80% or more. Over a machine’s 10+ year lifespan, this translates into substantial long-term savings.

Massive Productivity Gains

Increasing throughput from 30 to 300 sachets/min allows businesses to handle more orders, reduce lead times, and grow market share. In an 8-hour shift, an FL20-3200 can handle 144,000 sachets—ten times the output of manual methods.

Improved Product Quality

Automation removes human inconsistencies, delivering uniform results and lowering defect rates. This not only reduces waste and rework but also strengthens brand reputation.

Fast Return on Investment (ROI)

Between labor savings, higher productivity, and reduced waste, most companies recover their investment in an Automatic Sachet Counting Machine within 12–18 months.

Smart Automation Features

Remote Monitoring

Operators can manage and adjust settings via a touch-screen HMI interface or remote access, enabling faster response to production needs.

Real-Time Feedback

Sensors monitor operational data (speed, counts, alignment) and adjust machine performance instantly for continuous optimization.

Preventive Maintenance Alerts

The system can flag potential issues before they cause downtime, extending equipment life and maintaining peak efficiency.

The Comprehensive After-Sales Support You Can Rely On

While the performance of the feeding system is essential, excellent after-sales service is equally critical. Businesses need continuous support to ensure their equipment operates optimally throughout its lifecycle.

Training and Support

We offer comprehensive training programs that cover machine operation, maintenance procedures, and troubleshooting. Our training is designed to equip your staff with the skills necessary to operate the feeding system efficiently. Whether in-person or online, our training is tailored to meet the specific needs of your team.

Remote Diagnostic Support

In case of technical issues, our systems feature remote diagnostic capabilities that allow our engineers to access your machine’s data and provide troubleshooting assistance. This reduces downtime and ensures that your production line keeps running smoothly.

On-Site Technical Assistance

For more complex issues that require hands-on attention, our team of experienced engineers is available to provide on-site support. Whether you need maintenance or an emergency repair, our engineers are ready to help restore your machine to optimal performance quickly.

Case Studies

Food Manufacturer Efficiency Boost

A leading condiment producer upgraded from manual handling to an FL14-2900 model.

Before: 4 workers, 25–30 sachets/min, 2–3% error rate

After: 1 operator, 100–120 sachets/min, <0.1% error rate

Savings: 18,000 USD/year in labor, improved delivery times, near-zero complaints.

Pharmaceutical Quality Upgrade

A herbal medicine manufacturer installed an FL20-3200, meeting GMP hygiene standards and eliminating manual contact. The machine ran 6 months without downtime and passed rigorous government quality inspections.

Conclusion: Your Trusted Partner in Automation

The Automatic Sachet Counting Machine is more than a piece of equipment—it’s a strategic investment in productivity, quality, and cost reduction. With robust engineering, smart automation, and full-service support, it becomes the reliable backbone of your packaging line.

Whether you’re a small producer scaling up or an established manufacturer optimizing operations, our sachet sorting and counting solutions ensure you stay competitive in an evolving market.