Introduction: Small Components, Big Impact

In the world of industrial machinery, the ways humans interact with machines are endlessly diverse. From simple buttons to complex touchscreens, every point of contact defines the operational experience. However, in this digital age, one category of “traditional” components remains indispensable: manual adjustment knobs and handles.

Whether it’s adjusting the tension on a conveyor belt in a packaging line, fine-tuning the height of precision equipment, or opening an electrical cabinet door, these seemingly inconspicuous “small components” are actually the most direct and frequent physical touchpoints between operators and equipment. Their design quality directly impacts operational efficiency, safety, and even the operator’s comfort throughout the day.

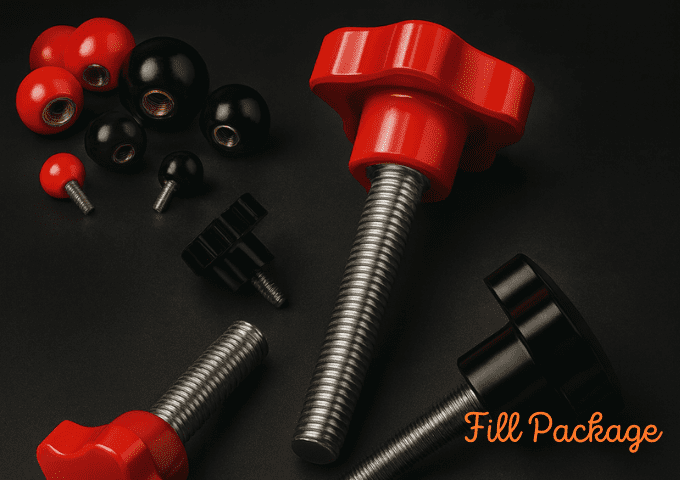

Today, we’ll dive deep into three types of adjustment components that look similar but each have their own unique strengths: Star Knobs, Ball Knobs, and Ball Handles. While they all provide manual adjustment functionality, they differ fundamentally in torque, operation method, space requirements, and ergonomics.

This article will help machine manufacturers, parts wholesalers, and equipment maintenance personnel fully understand these three components and make the best choice in real-world applications.

Part 1: Common Ground — Why Do We Need Them?

Before diving into the differences, let’s first understand the shared value of these three components.

Core Functions

1.Provide Reliable Grip

Whether it’s an operator wearing gloves or a technician working in an oily environment, these components must provide a safe, non-slip gripping surface.

Whether it’s an operator wearing gloves or a technician working in an oily environment, these components must provide a safe, non-slip gripping surface.

2.Enable Precise Rotation/Adjustment

From micrometer-level precision adjustments to centimeter-level rapid positioning, knobs and handles allow operators to precisely control machine states.

From micrometer-level precision adjustments to centimeter-level rapid positioning, knobs and handles allow operators to precisely control machine states.

3.Quick Locking and Release

During changeovers, maintenance, or emergencies, operators need to be able to quickly lock or release components without tools.

During changeovers, maintenance, or emergencies, operators need to be able to quickly lock or release components without tools.

Common Materials and Their Characteristics

Material | Characteristics | Typical Applications |

Plastic (Nylon, ABS) | Electrical insulation, lightweight, low cost, chemical resistant. | Electrical cabinets, control panels, general industrial equipment (mainstream choice for packaging machinery). |

Bakelite (Phenolic Resin) | Heat resistant, high rigidity, dimensional stability, classic industrial aesthetic. | High-temperature environments, premium equipment, applications requiring solid feel. |

Aluminum Alloy | Lightweight, high strength, attractive, corrosion resistant (anodized). | Premium equipment, visible control panels, applications requiring aesthetics (rarely used in packaging industry). |

Stainless Steel | Highest strength, corrosion resistant, food-safe, washable. | Food-contact zones, extreme environments (specialized packaging applications). |

Rubber-Coated | Non-slip, comfortable, shock-absorbing. | Applications requiring prolonged gripping or high-frequency operation. |

Material Selection in Packaging Machinery: In packaging equipment, plastic (nylon) and Bakelite account for over 90% of the market share because they achieve the optimal balance between cost, safety (electrical insulation), durability, and practicality. While aluminum and stainless steel offer excellent performance, they are rarely used for adjustment components in the packaging industry due to high cost, electrical conductivity, and weight factors.

Installation Methods

Most knobs and handles feature standard threaded hole designs, with common specifications including:

- Metric: M6, M8, M10, M12

- Imperial: 1/4″-20, 5/16″-18

They can be screwed directly into threaded holes on equipment (female-threaded knobs) or fixed via integrated studs (male-threaded knobs). Some premium products also offer quick-clip or magnetic mounting options.

Part 2: Detailed Analysis and Comparison

Now, let’s use a detailed comparison table to clarify the differences between these three components once and for all.

Feature | Star Knobs | Ball Knobs | Ball Handles |

Appearance & Design | Multi-lobed star-shaped radial design, largest profile, typically with 5-6 “star lobes”. | Complete spherical shape, most compact, smooth or textured surface. | Spherical head + rod-shaped handle, like a combination of ball and rod, variable rod length. |

Core Advantage | Provides maximum torque, fingers can reach deep into star lobes for leverage, ideal for scenarios requiring strong tightening. | Space-saving, sleek and modern appearance, flexible operation (can be gripped from any angle), ideal for frequent fine adjustments. | Provides maximum leverage and control distance, accommodates both rotation and pull/push actions. Distance from mounting point saves effort. |

Typical Operations | High-force rotation, locking (e.g., fixture locking, large equipment adjustment). | Fine rotation, frequent adjustment (e.g., height adjustment, quick positioning). | Rotation, pulling, prying, serving as door handles (e.g., machine tool doors, inspection equipment covers). |

Feel & Ergonomics | Solid grip, large contact area, slip-resistant. Suitable for applications requiring high force. | Smooth feel, suitable for fingertip operation, but sustained high-force operation may be tiring. | Most comfortable grip (especially with rod), suitable for gloved operation, can perform complex actions. |

Space Requirements | Large radial space requirement, needs significant operating clearance. | Small overall volume, but requires some operating clearance (finger grip space). | Requires certain swing radius space (determined by rod length). |

Torque Capacity | ⭐⭐⭐⭐⭐ Highest | ⭐⭐⭐ Medium | ⭐⭐⭐⭐⭐ Highest (via leverage) |

Operation Speed | ⭐⭐⭐ Medium | ⭐⭐⭐⭐⭐ Fastest | ⭐⭐⭐ Medium |

Aesthetics | ⭐⭐⭐ Strong industrial feel | ⭐⭐⭐⭐⭐ Modern, clean | ⭐⭐⭐⭐ Professional, functional |

Part 3: How to Choose? — Scenario-Based Guide

Choosing the right knob or handle is all about matching your specific application scenario. Here’s a practical decision guide:

Choose Star Knob When:

✅ Extremely high torque is needed – For example, locking conveyor guide rails, securing heavy fixtures, and adjusting mechanisms requiring strong tightening.

✅ Equipment vibrates heavily, and loosening is a concern – Star design provides a larger contact area, less likely to loosen from vibration.

✅ Visual indication of “high-force operation required” is needed – The star appearance itself is a visual cue telling operators this requires force.

✅ Operation frequency is low – If frequent adjustment isn’t needed, the large size of star knobs won’t be an issue.

✅ Equipment vibrates heavily, and loosening is a concern – Star design provides a larger contact area, less likely to loosen from vibration.

✅ Visual indication of “high-force operation required” is needed – The star appearance itself is a visual cue telling operators this requires force.

✅ Operation frequency is low – If frequent adjustment isn’t needed, the large size of star knobs won’t be an issue.

Typical Packaging Machinery Applications:

- Securing guard panels on VFFS machines

- Locking conveyor side panels and guide rails

- Adjusting sealing jaw pressure mechanisms

Choose Ball Knob When:

✅ Space is limited – Spherical design is most compact, suitable for confined installation spaces.

✅ Sleek, streamlined aesthetics are desired – Spherical appearance is modern and clean, suitable for visible control panels.

✅ Fine, frequent adjustments are performed – For example, quickly adjusting sensor height, fine-tuning guide rail position, frequent changeover operations.

✅ Gripping from any angle is required – Spherical design has no “dead angles”, can be easily gripped from any direction.

✅ Sleek, streamlined aesthetics are desired – Spherical appearance is modern and clean, suitable for visible control panels.

✅ Fine, frequent adjustments are performed – For example, quickly adjusting sensor height, fine-tuning guide rail position, frequent changeover operations.

✅ Gripping from any angle is required – Spherical design has no “dead angles”, can be easily gripped from any direction.

Typical Packaging Machinery Applications:

- Former height adjustment on VFFS machines

- Quick positioning screws on conveyors

- Photoelectric sensor bracket adjustment

- Parameter adjustment knobs on control panels

Choose Ball Handle When:

✅ Both rotation and pull/push/lift actions are needed – For example, door handles that require both rotation to lock and pulling to open.

✅ Operators may wear gloves – Rod design provides larger grip area, easy to operate even with thick gloves.

✅ Serving as door/cover opening handle – Ball handles are ideal for machine tool doors, electrical cabinet doors, inspection covers.

✅ Leverage force application is needed – For example, tensioning conveyor belts, locking rotating parts, clamping workpieces.

✅ Operators may wear gloves – Rod design provides larger grip area, easy to operate even with thick gloves.

✅ Serving as door/cover opening handle – Ball handles are ideal for machine tool doors, electrical cabinet doors, inspection covers.

✅ Leverage force application is needed – For example, tensioning conveyor belts, locking rotating parts, clamping workpieces.

Typical Packaging Machinery Applications:

- Inspection door handles on VFFS machines

- Tension adjustment levers on conveyors

- Opening handles for electrical cabinet doors

- Inspection cover handles on multihead weighers

- Safety fence door handles on palletizers

Part 4: Advanced Considerations and Emerging Trends

Material Evolution: Beyond the Basics

Modern industry demands increasingly sophisticated knobs and handles, and materials continue to evolve:

- Anti-Static Materials: In electronics manufacturing and flammable/explosive environments, anti-static plastic knobs are mandatory.

- Color-Coded Identification: Different colored knobs distinguish functional zones or operation priorities (e.g., red = emergency, green = routine, yellow = warning).

- Glow-in-the-Dark: In low-light environments or for equipment operated at night, luminous knobs improve visibility and safety.

- Foldable/Retractable Handles: In extremely confined spaces or where snagging hazards must be avoided, foldable ball handles are ideal.

Installation Tips: Details Make the Difference

- Use Washers: In vibrating environments, spring washers or lock washers effectively prevent knob loosening.

- Prevent Loosening: For critical locations, use thread-locking compounds (like Loctite) or double-nut locking.

- Adapt to Different Shaft Specifications: If equipment thread specifications are non-standard, use thread adapters or custom knobs.

Industry Trends: Personalization and Intelligence

- Personalized Customization: More and more machine manufacturers print their logos or brand colors on knobs to enhance brand recognition.

- Ergonomic Soft-Rubber Combinations: Hard plastic or metal core + soft rubber outer layer combination designs ensure both strength and comfort.

- Design Applications in Consumer Electronics and Smart Homes: Despite touchscreen proliferation, premium audio equipment, coffee machines, and smart home devices still favor exquisite metal knobs because they provide irreplaceable tactile feedback and ritual sense.

Part 5: Inventory Recommendations for Parts Wholesalers

If you’re a parts wholesaler looking to build a fast-turnover, high-profit knob and handle inventory, here are practical recommendations:

The 80/20 Rule: Focus on Best-Sellers

- The vast majority of demand will be covered by:

- Female-threaded plastic (nylon) star knobs: M6, M8, M10 specifications

- Female-threaded plastic (nylon) ball knobs: M6, M8, M10 specifications

- Adjustable ball handles (with ratchet): M8, M10 specifications

Material Focus

- Primary Inventory (90%+): Plastic (nylon) and Bakelite components.

- Secondary Inventory (rare): Small quantities of aluminum or stainless steel for niche demands, but don’t overstock.

Offer “Good, Better, Best” Options

- Good: Standard plastic/nylon (meets most needs, price competitive).

- Better: Bakelite (for high-temperature or premium-feel customers).

- Best: Aluminum or stainless steel (for niche hygienic or aesthetic applications, but low demand).

Conclusion: Small Components, Big Wisdom

Star knobs, ball knobs, and ball handles—these three seemingly simple components actually embody rich engineering wisdom and ergonomic considerations. By understanding their respective functions—star knobs for torque, ball knobs for speed, ball handles for force—and recognizing that plastic and Bakelite are the industry-standard materials for packaging machinery, machine manufacturers can build better, more cost-effective machines, and wholesalers can stock smarter, more profitable inventories.

Remember: Choosing the right knob isn’t just choosing a component—it’s choosing the operator’s daily work experience.

Looking for high-quality plastic and Bakelite adjustment components for your packaging machinery? Contact us to explore our wide range of star knobs, ball knobs, and ball handles in various sizes, and select the most suitable “interaction interface” for your equipment.