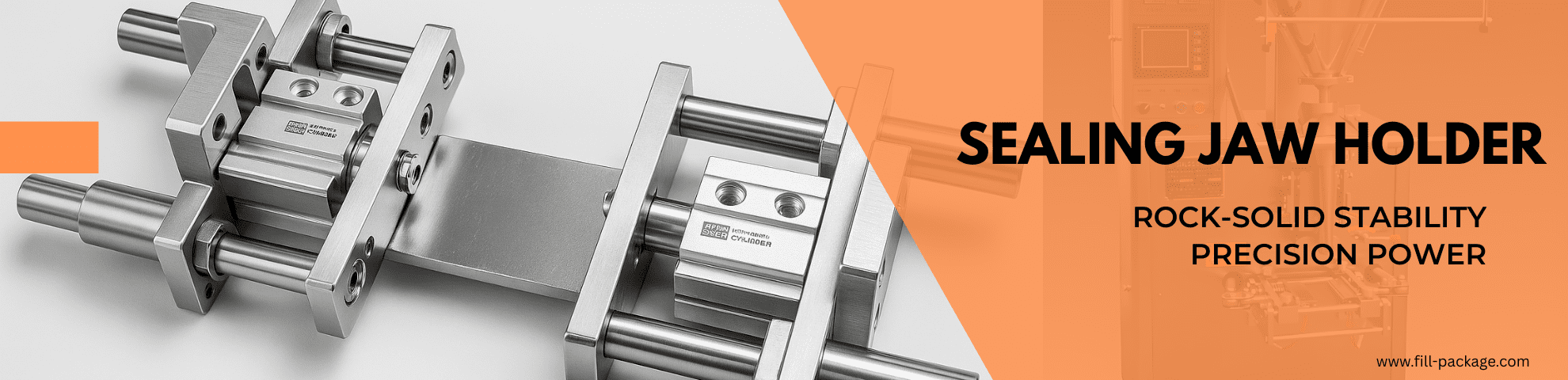

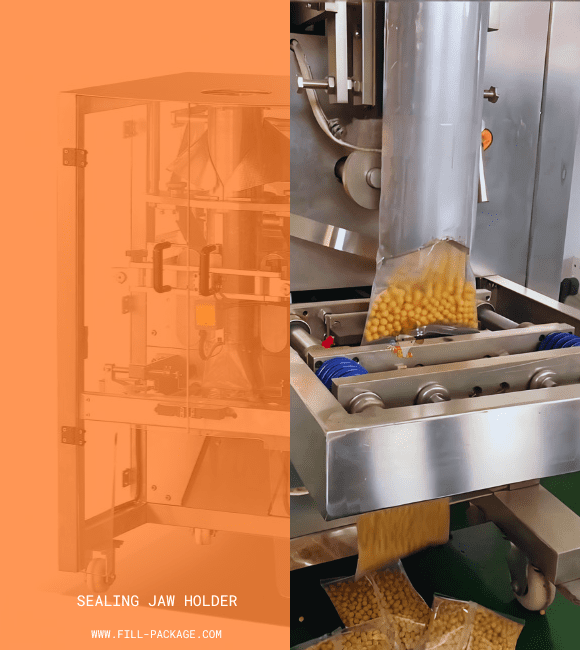

Model 320 Universal Pneumatic Sealing Jaw Holder

Product Overview: The Unyielding Skeleton of Your Sealing System

The Model 320 Universal Pneumatic Sealing Jaw Holder, also known as a Jaw Mounting Bracket or Pneumatic Jaw Frame, is the chassis and powertrain of a VFFS packaging machine’s sealing unit. It not only provides a rigid mounting platform for the horizontal and vertical sealing jaws but also integrates the pneumatic drive system that powers the precise, forceful sealing motion. A high-rigidity, high-precision sealing jaw holder is fundamental to ensuring consistent seal quality, increasing production speed, and reducing failure rates.

We deliver more than a simple metal frame; we provide the cornerstone that ensures the long-term, trouble-free operation of your—and your customers’—packaging equipment.

As an equipment manufacturer or a seasoned parts supplier, you understand the profound impact a seemingly ‘rugged’ component like the jaw mounting bracket has on overall machine performance. Any deformation or displacement in the jaw frame is magnified at the sealing jaws, ultimately resulting in rejected packages. Our Model 320 Universal Holder is engineered to conquer these challenges.

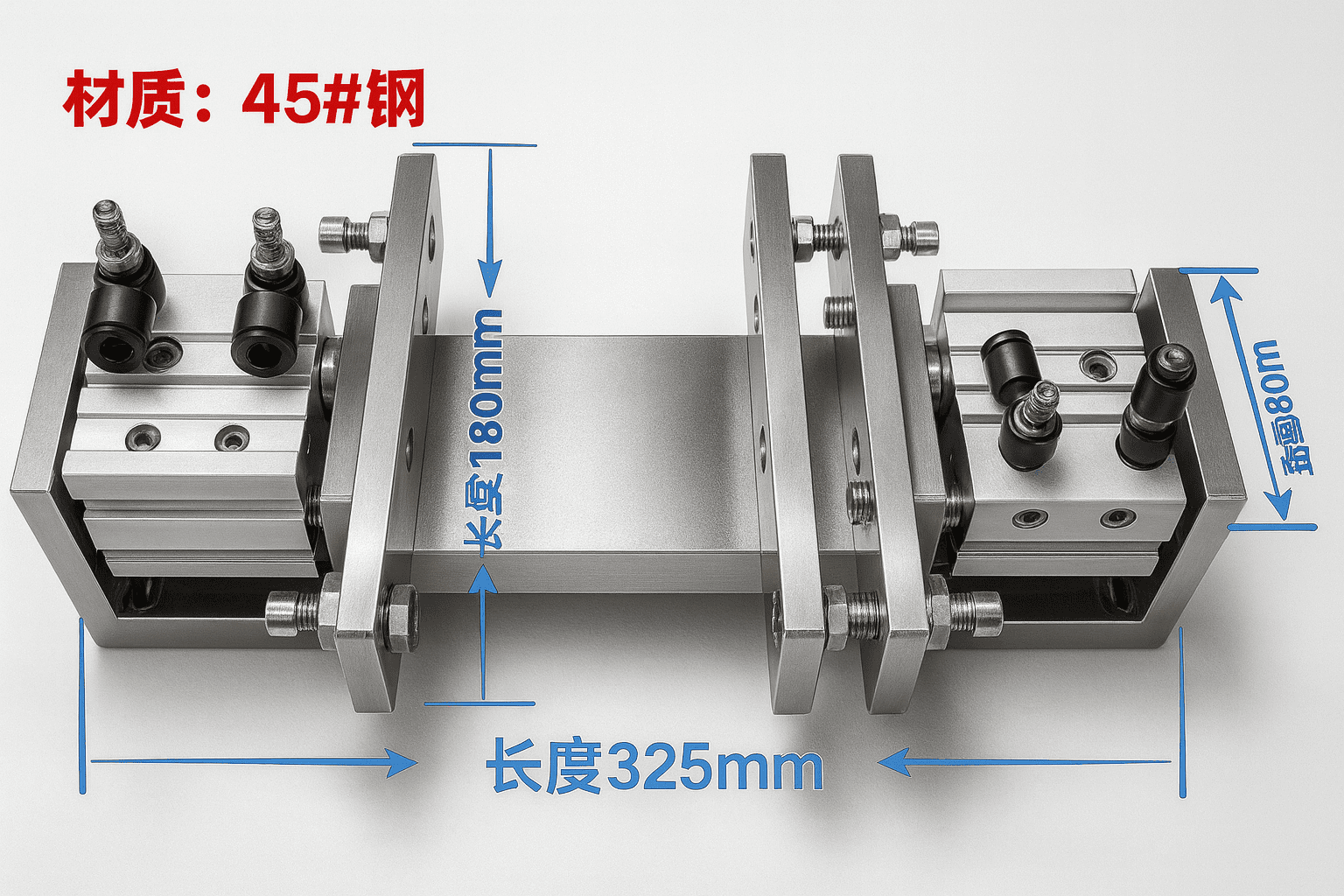

Material Showdown: Iron, Aluminum, or Steel for Your Jaw Mounting Bracket?

We offer three core material choices to meet diverse equipment positioning needs, from economy to high-performance.

Feature Comparison | Cast Iron | Aluminum Alloy | Steel / Stainless Steel |

Core Advantage | Cost-Effective, Good Vibration Damping | Lightweight, Fast Heat Dissipation | High Strength, High Durability |

Weight | Heavy | Lightest | Heavier |

Best-Use Scenario | Standard, cost-sensitive machines with moderate speed requirements. | High-speed machines where reducing motion inertia and motor/cylinder load is critical. | Applications demanding extreme rigidity, harsh environments (e.g., high humidity, corrosive), or food-grade cleanliness. |

Recommendation | The reliable choice for economy-focused equipment. | The top choice for performance upgrades to boost speed and responsiveness. | The standard for high-end equipment and the food/pharmaceutical industries. A build-it-once, build-it-right solution. |

Performance & Compatibility

Applicable Models: Specifically designed for Model 320 and similarly sized VFFS machines.

- Universality: The structure is compatible with various sealing configurations, including horizontal seal, vertical seal, back seal, and 3-side seal, making it a truly universal bracket.

- Drive System: Designed for pneumatic actuation with pre-drilled mounting holes for standard cylinders.

- Customization Service: We can customize mounting holes and dimensions based on your specific machine drawings or requirements.

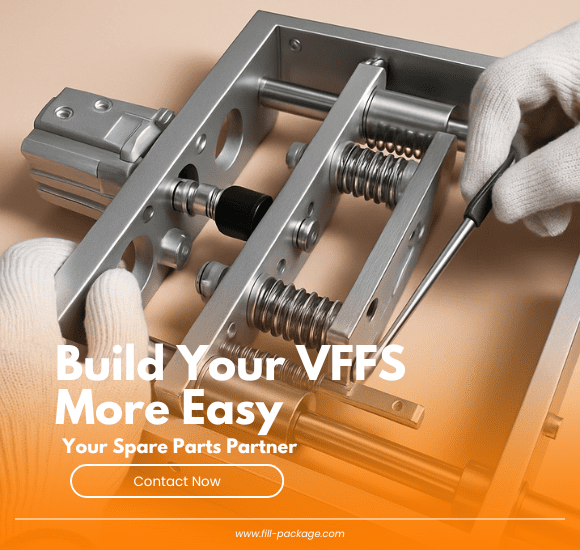

Replacement & Maintenance Guide Replacement Tutorial (Professional installation recommended)

Tools Required: Allen wrench set, open-end wrenches, pipe wrench, marker pen, clean cloth.

- Safety First: Shut off the main power and main air supply. Completely vent all residual pressure from the pneumatic system.

- Dismount Jaws: First, remove the horizontal/vertical sealing jaws from the old jaw holder and set them aside safely.

- Mark & Disconnect Air Lines: Use a marker to label the air tube connections on the cylinder, then disconnect the tubes and solenoid valve connectors.

- Remove Old Bracket: Loosen the bolts securing the entire jaw mounting bracket to the machine’s main frame and remove the old assembly.

- Install New Bracket: Mount the new jaw frame onto the machine, ensuring it is level and stable, then tighten the mounting bolts.

- Reassemble & Commission: Re-install the cylinder, reconnect the air lines, and mount the sealing jaws. Turn on the air supply and test the bracket’s movement at low speed to check for smoothness and interference. Finally, perform a precise jaw alignment.

Maintenance Best Practices

- Regular Tightening: Monthly, check all connection bolts to ensure none are loose.

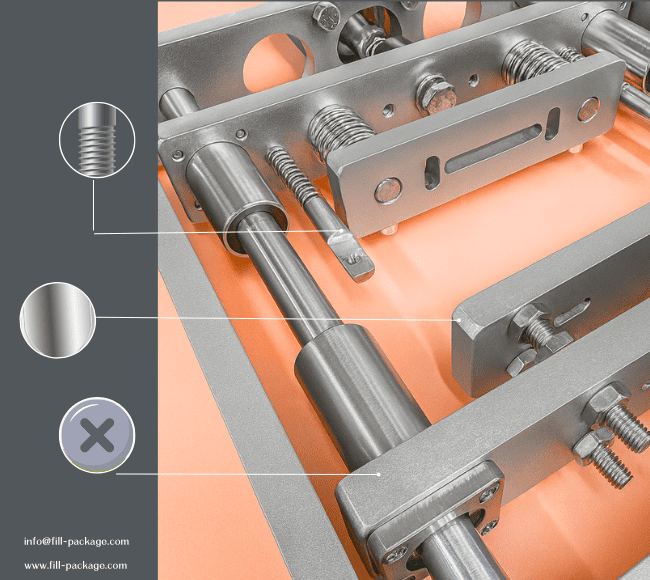

- Stay Lubricated: Regularly apply designated grease to the guide rails and sliders to ensure smooth motion.

- Air System Check: Periodically inspect air tubes for aging or cracks and fittings for leaks. Address any issues promptly.

- Keep Clean: Regularly remove dust and film debris from the bracket and guide rails to prevent blockages.

- Are Your Customers Complaining About These 'Chronic' Sealing Issues?

This is our highest-priority problem to solve for you. When sealing problems persist, and replacing jaws or adjusting parameters fails, the root cause often lies with the sealing jaw holder itself.

End-User Pain Point | Root Cause Analysis (Likely from the Jaw Holder) | Our Solution: The High-Rigidity Sealing Jaw Assembly |

Inconsistent sealing pressure | Insufficient rigidity in the jaw frame, causing micro-deformations during high-frequency operation. | Reinforced Structural Design: We use Finite Element Analysis (FEA) to optimize the structure, enhancing its resistance to deformation and ensuring constant sealing pressure every time. |

Constant seal misalignment | Wear and tear on the guide rails or sliders, creating play and wobble in the jaw’s movement. | High-Wear-Resistance Guide System: Utilizes high-hardness precision guide rails and self-lubricating sliders to guarantee long-term, high-precision motion, eliminating displacement errors. |

Inability to increase machine speed | Excessive weight of the jaw assembly, causing inertia that slows cylinder response and increases vibration. | Lightweight Material Options: We offer an Aluminum Alloy option to significantly reduce the weight of moving parts, decrease inertia, and enable higher operational speeds. |

Excessive vibration and noise | Loose connection bolts from long-term use or metal fatigue in the bracket itself. | Premium Materials & Precision Assembly: We select top-grade metals, combined with high-precision machining and strict assembly protocols, to ensure tight connections and effective vibration. |

Related Product

Can replacing the sealing jaw holder increase my packaging speed?

Very likely. If you upgrade from a heavy cast iron bracket to a lightweight aluminum alloy jaw holder, the motion inertia is significantly reduced. This allows the pneumatic cylinder to actuate faster, creating the potential for increased overall machine speed.

How do I know if I need to replace the bracket instead of repairing it?

If you have severe guide rail wear, irreversible deformation of the main frame, or damage to critical mounting holes, a repair is often not cost-effective or reliable. Replacing it with a new, high-precision jaw mounting bracket is the more dependable choice.

Is your bracket compatible with my [Brand X] Model 320 machine?

Our Model 320 holder is a universal design compatible with the vast majority of standard 320 machines. To guarantee a 100% match, we recommend providing your machine’s mounting hole layout or confirming the specifications with our technical experts before purchasing.

Send Your Inquiry Today