A Costly Mistake That Could Have Been Avoided

A few months ago, I received an urgent call from a client in the baking industry. Their production line, which handles freshly baked cookies straight from the oven, was experiencing constant shutdowns. The problem? To save on initial costs, they had installed a standard black PVC conveyor belt.

The hot, oily cookies were degrading the belt at an alarming rate, causing it to stretch, slip, and eventually fail. Even worse, the sticky, greasy residue was nearly impossible to clean, creating serious hygiene concerns and triggering multiple production stoppages each day. The plant manager was frustrated: “We saved a few hundred dollars on the belt, but we’re now losing thousands every day in downtime and wasted product.”

This scenario is far more common than you might think. Choosing a conveyor belt may seem straightforward, but selecting the wrong one can cripple your production efficiency, compromise product quality, inflate maintenance costs, and even create food safety issues.

The conveyor belt is the circulatory system of your packaging line. When it fails, everything stops. When it’s optimised, your entire operation flows smoothly.

This comprehensive guide will walk you through the five critical factors you must consider when selecting a conveyor belt and provide an in-depth comparison of the most common materials on the market. By the end, you’ll have a clear framework to make an informed decision that boosts productivity and protects your bottom line.

Why Conveyor Belt Selection Matters More Than You Think

Before we dive into the selection criteria, let’s understand why this decision is so critical.

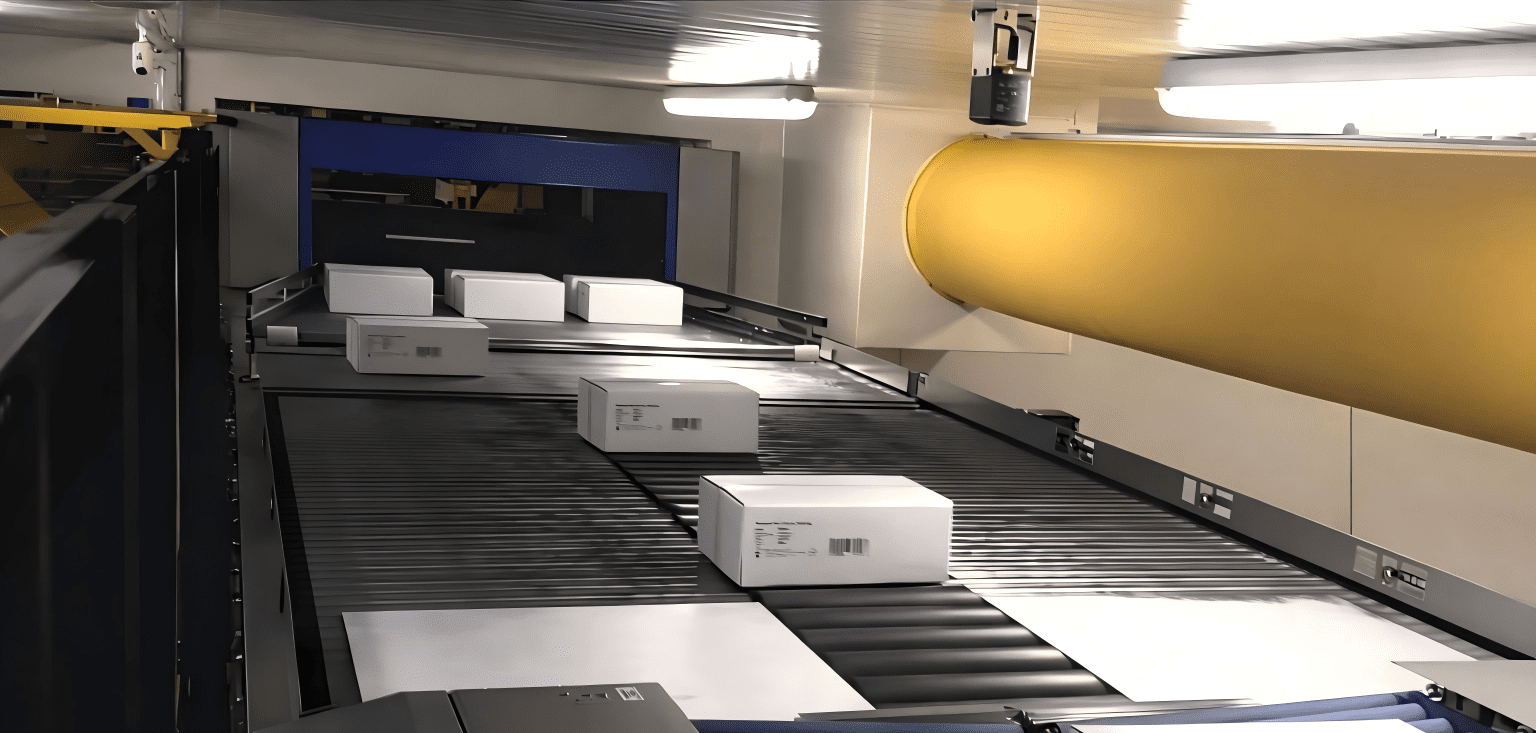

1.Impact on Production Efficiency

A well-matched conveyor belt keeps your line running at optimal speed with minimal interruptions. A poorly chosen belt creates bottlenecks, requires frequent adjustments, and causes unexpected downtime. In high-volume operations, even a few minutes of downtime per shift can translate to significant production losses.

2.Impact on Product Quality

The conveyor belt is often in direct contact with your product. An inappropriate belt can damage delicate items, contaminate food products, or fail to maintain the proper orientation of packages as they move through the line. For food and pharmaceutical applications, the wrong belt material can even pose health risks.

3.Impact on Maintenance Costs

A cheap belt that requires constant replacement or causes frequent line stoppages will cost far more over its lifetime than a higher-quality option. The Total Cost of Ownership (TCO) includes not just the purchase price, but also installation, maintenance, downtime, and eventual replacement costs.

4.Impact on Compliance and Safety

In regulated industries like food processing and pharmaceuticals, your conveyor belt must meet strict hygiene and safety standards. Non-compliant materials can result in failed audits, product recalls, and regulatory fines.

Now that we understand the stakes, let’s explore how to make the right choice.

The 5 Critical Factors for Choosing a Conveyor Belt

Before you even look at materials or suppliers, you must first become an expert on your own application. Answering these five questions thoroughly is the foundation of the entire selection process.

Factor 1: Product Characteristics

The product you are conveying dictates almost everything about your belt selection. You need to analyze:

- Weight and Volume: Heavy products require belts with higher tensile strength and robust support structures. A belt designed for lightweight packages will quickly fail under the stress of heavy items. Conversely, an over-engineered belt for light products is an unnecessary expense.

- Shape and Stability: Round or irregularly shaped items may roll or shift during transport. These products often require belts with cleats, sidewalls, or textured surfaces to maintain stability. Flat, stable products can use smooth belts.

- Surface Properties: This is where many selection errors occur. Consider whether your product is oily, sticky, abrasive, or fragile. Oily products, like fried foods or greasy parts, require oil-resistant materials such as polyurethane (PU). Sticky products, like candies or adhesive-backed items, need non-stick surfaces. Abrasive products demand wear-resistant materials. Fragile items, such as glass bottles or delicate electronics, require smooth, gentle transfers.

- Temperature: Is your product hot, cold, or at ambient temperature? Hot products, like our client’s freshly baked cookies, require heat-resistant materials such as metal mesh or specialized high-temperature belts. Frozen products need belts that remain flexible in sub-zero conditions.

Understanding these characteristics in detail will immediately eliminate many unsuitable options.

Factor 2: Production Environment

Where will the conveyor operate? The environment is just as important as the product itself.

- Ambient Temperature and Humidity: Extreme cold can make some belt materials brittle and prone to cracking. High heat and humidity can cause belts to stretch, warp, or degrade. If your facility experiences wide temperature swings, you need a material that can handle that range.

- Cleanliness and Hygiene Requirements: Food, pharmaceutical, and electronics manufacturing demand stringent hygiene standards. This requires food-grade materials (such as FDA-compliant polyurethane) and belt designs that are easy to clean with no crevices where bacteria, allergens, or contaminants can hide. Belts in these environments often need to withstand aggressive cleaning chemicals and high-pressure washdowns.

- Chemical Exposure: Will the belt be exposed to cleaning agents, acids, alkalis, or other chemicals during operation or cleaning? You must choose a material that is chemically resistant to these substances. A belt that degrades when exposed to your standard cleaning solution is a recipe for frequent replacements.

- Dust and Debris: Dusty environments can clog belt mechanisms and cause premature wear. Open-mesh designs may be more suitable in these conditions.

Factor 3: Conveyor Speed and Capacity

How fast and how much do you need to move? This is a function of both belt speed and width.

- Belt Speed: The speed must match the pace of your entire production line. While higher speed generally means higher throughput, a speed that is too fast for the product can cause instability, misalignment, and damage. Delicate positioning tasks, such as feeding products into a form-fill-seal machine, often require slower, more controlled speeds. The belt speed should be synchronized with upstream and downstream equipment to avoid accumulation or gaps.

- Belt Width: The belt should be significantly wider than the product to prevent items from falling off the edges. A common rule of thumb in the industry is that the belt width should be at least 2 to 3 times the product’s largest dimension (width or length, depending on orientation). A wider belt also allows for higher capacity at the same speed, as you can run multiple lanes of product side by side.

- Throughput (Capacity): Your desired throughput—measured in items per minute or kilograms per hour—is a function of belt speed, width, and product spacing. Calculate this carefully to ensure the conveyor is not a bottleneck in your line. If your target is 120 bags per minute and your current belt can only handle 100, you’re leaving money on the table.

Factor 4: Conveyor Path and Layout

Is it a simple straight line, or a more complex journey through your facility?

- Incline and Decline: Transporting products up or down an incline requires a belt with a high-grip surface or cleats to prevent slippage. The steeper the incline, the more aggressive the grip needs to be. Standard smooth belts will fail on even modest slopes with certain products.

- Curves and Bends: Complex facility layouts with turns require specialised solutions. Curve belts or modular belts can navigate corners without compromising product stability. Traditional flat belts require transfer points at every turn, which are potential failure points and sources of product damage.

- Transfers: How does the product get on and off the belt? The transition to and from other machines is a critical point. Knife-edge transfers are often needed for small or unstable products to ensure a smooth handoff. Poor transfer design can cause jams, product damage, and downtime.

Factor 5: Budget and Total Cost of Ownership (TCO)

This is where many purchasing decisions go wrong. Don’t just look at the initial price tag.

- Initial Cost: This is the upfront purchase price of the belt. Materials like standard PVC are cheaper initially, which makes them attractive from a procurement standpoint.

- Maintenance and Lifespan: A cheaper belt that needs frequent replacement or causes more downtime can be far more expensive in the long run. A durable, well-chosen belt has a lower Total Cost of Ownership (TCO). For example, modular belts may have a higher initial cost, but the ability to replace a single damaged module instead of the entire belt significantly reduces maintenance costs and downtime.

- Downtime Costs: What does downtime cost your operation? For high-volume operations, even an hour of downtime can cost thousands of dollars in lost production. A belt that fails frequently is a hidden drain on profitability.

- Energy Efficiency: Certain belt materials have lower friction coefficients, which require less energy to drive. Over the years of operation, this can add up to significant savings.

The formula to remember is:

Total Cost of Ownership (TCO) = Initial Purchase Cost + Installation Cost + Maintenance Costs + Downtime Costs + Energy Costs – Residual Value

Always calculate TCO over the expected lifespan of the belt, not just the first year.

Material Matters: Comparing Common Conveyor Belt Types

Once you have a clear understanding of your needs based on the five factors above, you can select the right material. Here are the most common options in the packaging industry, with their strengths, weaknesses, and ideal applications.

1. PVC and PU Belts: The Versatile Workhorses

These are the most widely used belts in light-to-medium duty packaging applications. While often grouped together, they have important differences.

PVC (Polyvinyl Chloride): PVC is a cost-effective, general-purpose belt material. It offers decent resistance to abrasion and many chemicals, making it suitable for a wide range of non-demanding applications. However, it is not ideal for handling oils, greases, or extreme temperatures. PVC can become brittle in cold environments and may release harmful substances when exposed to high heat, making it unsuitable for direct food contact in many jurisdictions.

PU (Polyurethane): PU is the premium choice for food and pharmaceutical applications. It is highly durable, flexible, and resistant to oils, fats, and abrasion. Critically, it does not release harmful toxins, making it compliant with FDA and EU food-grade standards. PU is also easier to clean than PVC and more resistant to cracking and tearing. While it costs more upfront, its longevity and performance often make it the more economical choice over time.

Best For:

•PVC: General packaging, logistics, secondary packaging of dry goods, non-food applications where cost is a primary concern.

•PU: Primary food contact, bakery products, meat and poultry, dairy, confectionery, pharmaceuticals, cleanroom environments, and any application requiring FDA/EU compliance.

Case Study: A snack food manufacturer was using a standard PVC belt for their potato chip line. The oil from the chips was degrading the belt, requiring replacement every six months. After switching to a food-grade PU belt, they not only achieved FDA compliance but also extended the belt’s lifespan to over two years, saving thousands in replacement costs and downtime.

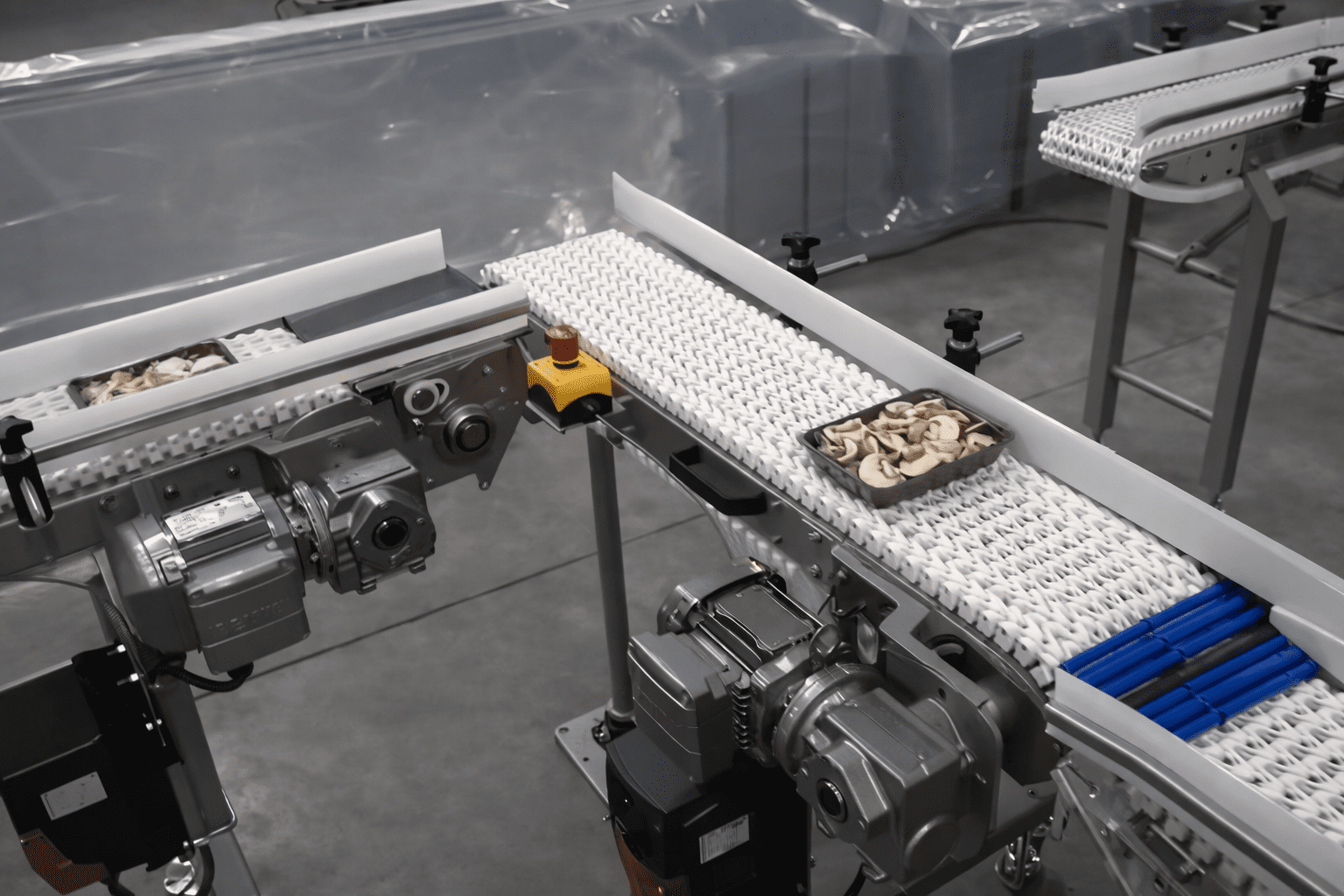

2. Modular Plastic Belts: The Maintenance Game-Changer

Modular belts represent a fundamentally different design philosophy. Instead of a single continuous loop, they are constructed from countless small plastic modules interlinked with plastic pins or rods. This design gives them unique advantages.

Easy Maintenance and Repair: This is the primary selling point. If a section of a modular belt is damaged—say, a bottle breaks and cracks a few modules—you only need to replace those specific broken modules, not the entire belt. This drastically reduces repair time and cost. What might have been a four-hour belt replacement becomes a 30-minute module swap.

High Flexibility and Configurability: Modular belts can be configured to go straight, make tight turns, spiral upward, and even travel up steep inclines, often within a single continuous system. This eliminates the need for multiple transfer points, which are common sources of product damage and line jams.

Excellent Drainage and Airflow: The open-grid design of many modular belts is perfect for applications that require drainage (such as washing lines) or airflow (such as cooling or drying tunnels). Liquids and air pass through the belt easily.

Durability: Modular belts are extremely durable and resistant to impact. They can handle heavy loads and rough handling.

Best For:

- Accumulation tables and buffering zones

- Complex conveyor layouts with multiple turns

- Washing and rinsing lines

- Cooling and drying applications

- High-maintenance environments where downtime is costly

- Bottling and canning lines

Case Study: A beverage bottling plant was using a standard flat belt on their accumulation table. When a bottle occasionally broke, they had to replace the entire belt—a four-hour job that required shutting down the line. After switching to a modular belt, they now replace a few damaged modules in under 30 minutes. The plant manager calculated that this change alone saved them over $20,000 per year in reduced downtime.

3. Metal Mesh Belts: The High-Temperature and Heavy-Duty Champions

When the environment gets extreme, you need metal. Metal mesh belts are typically made from stainless steel and are engineered for the harshest conditions.

Extreme Temperature Resistance: Metal mesh belts can handle everything from deep-freezing tunnels (down to -40°C or lower) to high-temperature baking ovens and frying lines (up to 1000°C for some speciality meshes). No plastic belt can compete in these environments.

Superior Durability and Strength: They are extremely strong and resistant to cuts, punctures, and abrasion. This makes them suitable for handling heavy products, sharp metal parts, or abrasive materials that would quickly destroy a plastic belt.

Easy to Clean and Sterilise: The open mesh structure allows for thorough cleaning and high-pressure washdowns. They can be sterilized with steam or harsh chemicals without degradation. This makes them ideal for food processing environments with strict hygiene requirements.

Chemical Resistance: Stainless steel is highly resistant to most acids, alkalis, and cleaning agents.

Best For:

- Baking ovens and proofing lines

- Frying and cooking lines

- Blast freezers and spiral freezers

- Drying and curing ovens

- Cooling tunnels

- Handling sharp or abrasive products (metal stampings, glass)

- High-pressure washdown environments

Considerations: Metal mesh belts are not suitable for small products that could fall through the openings. They are also the most expensive option and can be noisy in operation.

A Note on Rubber Belts

Rubber belts are the workhorses of heavy industry, commonly seen in mining, aggregate, and bulk material handling. They offer excellent abrasion resistance, high tensile strength, and can handle very heavy loads.

However, for most packaging applications, rubber belts are overkill. They are difficult to clean, making them unsuitable for food contact. They are also heavy, require significant drive power, and are not as precise as lighter belt materials. For general packaging, a high-quality PVC or PU belt is usually a more appropriate and cost-effective choice. This is why we do not typically supply rubber belts for packaging machinery.

At a Glance: Material Comparison Chart

To help you quickly compare your options, here’s a summary table:

Material | Key Advantages | Key Disadvantages | Best Applications | Relative Cost |

PVC | Low cost, versatile, good chemical resistance | Not oil-resistant, not for high temps, not food-safe in many regions | General packaging, logistics, secondary packaging | Contact us |

PU (Polyurethane) | Food-grade, oil-resistant, durable, easy to clean | Higher cost than PVC | Food processing, pharmaceuticals, cleanrooms, primary food contact | Contact us |

Modular Plastic | Easy repair (replace modules only), flexible layouts, excellent drainage | Higher initial cost, can be noisy | Complex paths, accumulation, washing/drying, high-maintenance areas | Contact us |

Metal Mesh (Stainless Steel) | Extreme temperature resistance, very durable, easy to sterilize | High cost, not for small items, and noisy | Ovens, fryers, freezers, washdowns, heavy-duty applications | Contact us |

Common Mistakes to Avoid

Even with the right information, it’s easy to make mistakes. Here are the most common pitfalls:

Mistake 1: Focusing Only on Initial Price

Buying the cheapest belt often leads to higher costs down the line due to frequent replacements and downtime. Always calculate Total Cost of Ownership (TCO).

Mistake 2: Ignoring Product Characteristics

Choosing a belt without fully understanding your product’s weight, temperature, and surface properties is a recipe for failure. A belt that works for dry cereal will not work for oily fried chicken.

Mistake 3: Overlooking Hygiene Requirements

In food and pharmaceutical applications, using a non-compliant belt can result in failed audits, product contamination, and costly recalls. Always verify that your belt meets the required standards (FDA, EU 10/2011, etc.).

Mistake 4: Incorrect Belt Width

A belt that is too narrow will cause products to fall off. A belt that is too wide wastes space and money. Follow the 2-3x rule for width.

Mistake 5: Not Consulting with Experts

Conveyor belt selection is complex. If you’re unsure, consult with a knowledgeable supplier or engineer who can analyze your specific application and recommend the best solution.

Conclusion: Your Partner in Productivity

Choosing the right conveyor belt is not a minor detail; it is a strategic decision that impacts your entire operation. By first analysing your product, environment, and production needs using the five critical factors, you can confidently select a material that will serve you reliably for years to come.

Moving from an ill-suited PVC belt to a food-grade PU belt, or from a standard flat belt to a problem-solving modular design, is an investment that pays for itself through increased uptime, lower maintenance costs, and guaranteed product quality.

Don’t let the wrong conveyor belt be the weak link in your production line. At our company, we specialise in helping packaging operations like yours find the perfect conveyor solution. Our team of experts can analyse your application, recommend a customised solution, and provide ongoing support to keep your line running smoothly.

Ready to optimize your conveyor system? Contact us today for a free consultation, or browse our full range of conveyor belt solutions to find the perfect match for your needs.

We’re not just selling belts; we’re partnering with you to build a more efficient, reliable, and profitable operation.