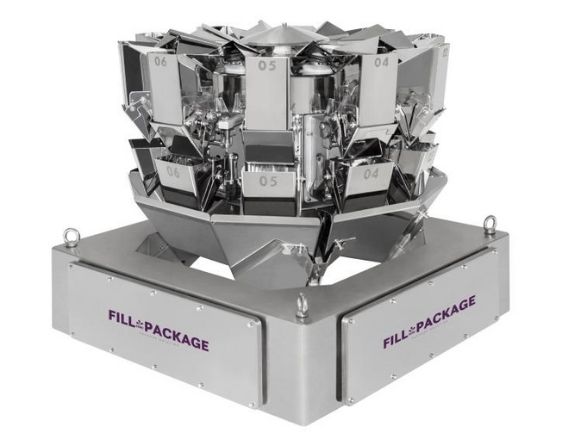

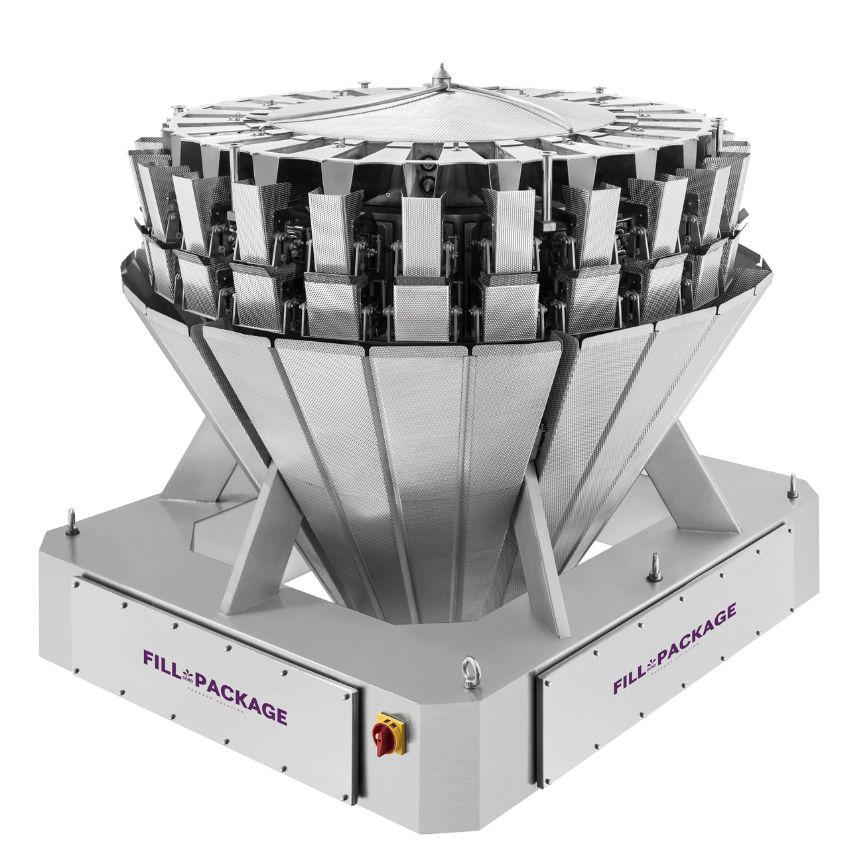

Standard Multihead Weighers

Our standard weighers family included 4 different kinds 10 Head ,11Head ,14 Head ,16Head &24 Head ,They take care of customer different needs .with different prices and speed .

- Stainless steel 304 housing cabint .

- Stainless steel 12″ friendly HMI design ,easy to operation

- Most electrical boards with 3 years warranty

- Electrical board hardware compatible with different programs

- Dia-coded AD module

Fill&Package Multihead Weigher

We have sold thousands of multihead weighers to world for a variety of package solutions ,including snack food ,pet food ,fruit,sea food ,seed ,tea ,medicinal ,canabis ,frozen food and meat package etc .

We are constantly innovating, launching more application solutions, and solving problems in the field of more automated weighing. We enjoy the process of R&D, manufacturing, and sharing, especially when users are satisfied, we are full of motivation to move forward , I believe that in the future, we will have more products, and more customers will use our weigher in more places, expecting

Technical Data

- 10 Head

- 11 Head

- 14 Head

- 16 Head

| Head No. | 10 |

| Hoper size | 1.3L/2.5 L |

| Max .Speed | 60 wpm |

| Single Weigh | 20-1000g |

| Accuracy | 0.5-1.5g |

| Power | 50Hz/60Hz |

| Head No. | 11 |

| Hoper size | 1.3L/2.5 L |

| Max .Speed | 60 wpm |

| Single Weigh | 20-1000g |

| Accuracy | 0.5-1.5g |

| Power | 50Hz/60Hz |

| Head No. | 14 |

| Hoper size | 1.3L/2.5 L |

| Max .Speed | 120wpm |

| Single Weigh | 20-1000g |

| Accuracy | 0.5-1.5g |

| Power | 50Hz/60Hz |

| Head No. | 16 |

| Hoper size | 1.5L/2.5 L |

| Max .Speed | 140 wpm |

| Single Weigh | 20-1000g |

| Accuracy | 0.5-1.5g |

| Power | 50Hz/60Hz |

Every process with our heart

Stainless steel 304 /316

General hardware uses 304 stainless steel ,and 316 stainless steel is used of stong corrosiveness producuts ,

At the same time ,sheet have 3 different surface treatments : flat ,dimple and Teflon- coated

Can bus control systerm

Since 2011, we have started to make our own programs, and continue to optimize in the direction of user experience. At the same time, make the hardware compatible with all programs

Beginners Can Handle It Easily

Free training is provided still customers know well how to install and operate the machine .the learing method : come to our company ,or learn form video o,or learn form video call .

Foods Our weigher can handle

More Multihead Weighes

- Weighers

- Data Sheet

| Material | Stainless steel 304 |

| HMI | 12″ stainless steel |

| Power | AC 220V ,50/60 Hz |

| Temperature | -10℃-40℃ |

| Speed | Depend on material |

| Waterpoof | IP64 /IP65 optional |

Related machines (4)

How To Inspection Before Delivery ?

All Multihead weighers will go through 3 steps inspections: pre-production, mid-production, and finish-production. Before production, the parts are sampled. During the production ,inspector will inspect each equipment and correct the defective parts in time. When the machine is completed , We will conduct further inspection on each component of the product, such as: line vibration plate, hopper, vibration machine, electrical components, etc., material testing, waterproof testing and aging testing , etc. to issue machines work well before shipment

Certifications (4)

Connecting a combination scale to existing package machine is easy .because the combination scale usually provides multiple connection methods and interface types to meet the data transmission requirements between different packaging machines . If the combination scale and existing package machines have the following methods: serial port connection (RS232 or RS485 interface), Ethernet connection, USB connection, and WIFI connection, serial port connection is the most commonly used method, it is the connection of wires between machines, so the connection is very simple, just use the corresponding wires to connect, or connect wirelessly.

The daily maintenance of combination scale is very important to ensure its normal operation, the following are some common maintenance methods:

Regular cleaning: The combination scale should be cleaned regularly to ensure that it is kept clean and hygienic, especially the parts in contact with food, such as vibrating plates, hoppers, chute etc. These parts are easy to get the food dirt, which not only affects the accuracy but also affects the food quality, so use a soft damp cloth or brush to clear contact metal parts to ensure that their surfaces are clean.

Prevent vibration and shock: the combination scale is a high-precision machine. which should be placed on a stable plane and try to avoid moving it which may damage parts such as the weighing pan and load cell .

Regular Calibration: Combination weigher should be calibrated regularly to ensure their accuracy. Calibration should be carried out under actual use conditions and compared with standard items to ensure the accuracy of the scale.

Avoid overloading: Combination scales should not be subject to over weight loads, which will damage the load cell or vibrating plate. Proper scale ranges and weight limits should be used to avoid overloading.

Regular Maintenance: weigher machine should be regularly maintained and inspected to ensure they work properly. If a problem is found, it should be repaired or replaced in time to ensure the long-term reliability and accuracy of the combination scale.

The above methods are for reference only. If you have more questions about the maintenance of multihead weigher packing machines , please feel free to communicate with us

Installing the combination scale is a very simple, because the main body has installed , and the installation tools are very common

- Hand electric drill: It is a necessary to remove the packing wooden box to improve efficiency.

- Measuring tools, such like multimeter, are used to measure the current at the phase place and whether the voltage is normal and stable.

- Wrench and screwdriver for tightening and loosening the screws, adjusting the fitting parts.

- Wire pliers, used for connection between antenna wires.

Most of the surface contact parts can be assembled without tools. Before installation, please read our manual carefully to ensure the correct and stable installation Feel free to contact us if you do not understand.

Spare parts shipped with combination sales are for some easily damaged accessories .for example, Load cell, bushing , connectors, fuses and so on. The purpose of these accessories is to facilitate the user to quickly replace the accessories for combination scale when they are damaged or need to be replaced, and to ensure the accuracy and performance of the combination scale. Therefore, when installing a combination scale, it is recommended that you keep these spare parts carefully, and use them for repair when necessary. At the same time, if you find any abnormality or damage to the parts, please contact our after-sales service center for replacement in time