Introduction: The Unsung Hero of Access and Safety

In the world of industrial machinery, components like motors, sensors, and controllers often take the spotlight. Yet, the humble industrial hinge plays an equally critical role, consequently governing every access panel, safety guard, and control cabinet door. A failing hinge doesn’t just mean a wobbly door; ultimately, it can lead to safety hazards, equipment misalignment, and costly downtime.

Unlike their residential counterparts, for instance, industrial hinges are engineered to withstand thousands of cycles, heavy loads, constant vibration, and often, harsh chemical or washdown environments. For machine manufacturers and parts wholesalers, therefore, understanding the nuances of industrial hinges is key to building reliable equipment and maintaining a profitable inventory.

This guide goes beyond the basics. Specifically, we’ll explore the different types of industrial hinges, provide practical selection and installation advice, and offer insights that your product datasheet might not cover.

Part 1: Beyond the Butt Hinge – A World of Specialized Movement

The standard butt hinge is a versatile workhorse, but modern machinery frequently demands more sophisticated control. As a result, understanding these specialty hinges can unlock significant design and usability improvements.

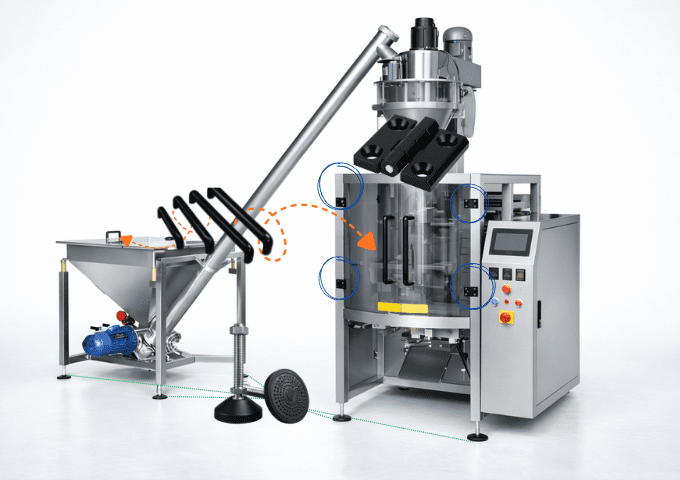

Hinge Type | Core Function | Best For | Packaging Machine Application |

Butt Hinge | Standard 180°/270° pivot | General purpose doors, panels, guards | The default choice for most access doors and electrical cabinets. |

Torque/Friction Hinge | Holds a door open at any angle | Lightweight inspection lids, HMI screen mounts | For example, keeping a control panel screen tilted at the perfect viewing angle for an operator. |

Detent Hinge (Positioning Hinge) | Clicks into place at pre-set angles (e.g., 90°, 120°) | Doors that need to be held open securely | Ensuring a heavy safety guard on a VFFS machine stays fully open during maintenance. |

Lift-Off Hinge | Allows for quick and tool-free door removal | Doors that need to be removed frequently for full access | For instance, quickly removing a side panel on a conveyor system for cleaning or jam clearing. |

Concealed Hinge | Installed inside the enclosure for a clean look and security | High-security cabinets, aesthetically critical designs | Securing a control cabinet door to prevent tampering and provide a sleek exterior. |

By choosing the right type, you can dramatically improve the user experience and safety of your machinery.

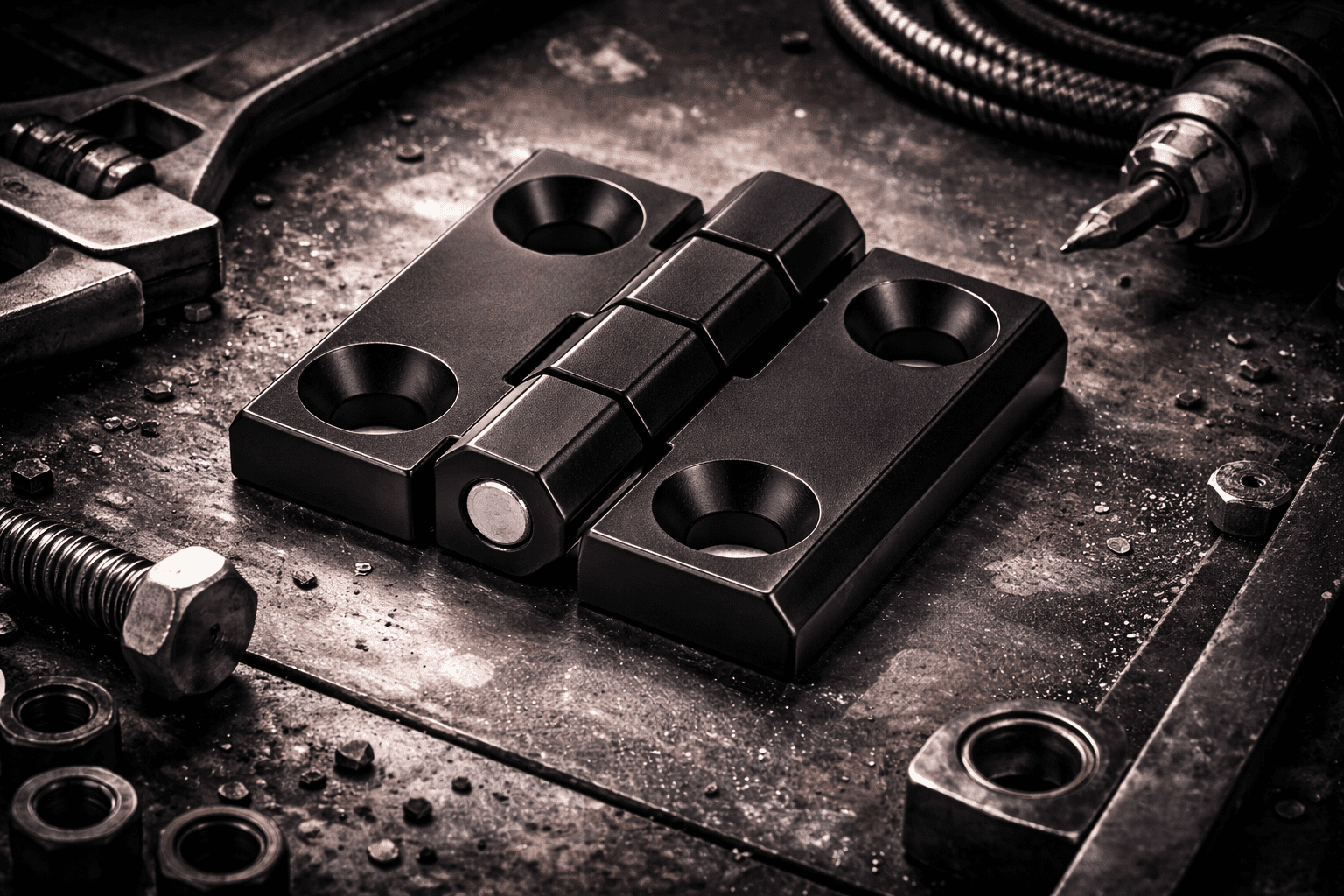

Part 2: Material & Finish Deep Dive

Your product page already outlines the core materials, but let’s frame it from a problem-solving perspective.

Material Selection for Optimal Performance

- Plastic (Nylon/ABS): This is the go-to for electrical cabinets and lightweight guards. Its key advantage is electrical insulation, which in effect prevents any chance of the door becoming live. It’s also cost-effective and resistant to many chemicals.

- Zinc Alloy: As the all-around workhorse, it offers a fantastic balance of strength, castability (for complex shapes), and cost. It’s perfect for most indoor machinery doors and panels that don’t face extreme corrosion.

- Stainless Steel: This remains the premium choice for harsh environments. If the machine will be washed down, exposed to corrosive chemicals, or is used in food/pharma, stainless steel is non-negotiable for its superior corrosion resistance and hygienic properties.

Choosing the Right Surface Finish

- Black Oxide Finish: This is more than just a color; in fact, it’s a conversion coating that provides moderate corrosion resistance and reduces friction. It’s a durable, cost-effective finish for zinc and steel hinges in standard industrial settings.

- Polished/Chrome Plated: This finish is for applications demanding high cleanliness and aesthetics. The smooth, non-porous surface is easy to clean and offers excellent corrosion resistance, making it ideal for food-grade or cleanroom equipment.

Part 3: A Simplified Guide to Load Calculation

While precise load ratings should always be confirmed with datasheets, here is a simplified framework to guide your initial selection.

Step 1: Determine the Door/Panel Weight

First, you must identify your starting point. Let’s say you have a steel panel that weighs 20 kg (approx. 44 lbs).

Step 2: Consider the Door’s Center of Gravity

Next, you need to account for leverage. The further the door’s center of gravity is from the hinge’s pivot point (i.e., the wider the door), the greater the cantilevered load on the hinge. A wide, short door, for example, puts more stress on hinges than a tall, narrow one of the same weight.

Step 3: Apply a Safety Factor

Crucially, never design to the exact load limit. Industrial environments involve dynamic forces like slamming doors, vibration, and accidental impacts.

- Static Applications: Use a minimum Safety Factor of 1.5.

- Dynamic/High-Vibration Applications: In contrast, use a Safety Factor of 2.0 to 3.0.

Step 4: Calculate and Select

Finally, you can perform the calculation.

- Calculation: (Door Weight × Safety Factor) / Number of Hinges

- Example: (20 kg × 2.0 Safety Factor) / 2 Hinges = 20 kg per hinge.

You would then select a hinge with a rated static load capacity of at least 20 kg. Additionally, always check both radial (downward) and axial (outward) load ratings if available.

Part 4: Installation Best Practices

A high-quality hinge can fail if installed improperly. This is a critical value-add for machine manufacturers.

- Ensure Perfect Alignment: The most common cause of premature hinge failure is misalignment. Therefore, use a laser level or a precision straight edge to ensure the pivot pins of all hinges on a door are perfectly coaxial (aligned on the same axis).

- Choose the Right Fasteners: Don’t pair a heavy-duty hinge with undersized screws. Instead, use the fastener size recommended by the hinge manufacturer. For high-vibration environments, you should also consider using locking nuts or thread-locking compound.

- Use Shims for Adjustment: If the mounting surfaces are not perfectly flush, use thin metal shims to align the hinges. You should not force them into place by overtightening screws, which can warp the hinge leaf.

- Avoid Welding: Unless the hinge is specifically designed as a weld-on hinge, do not weld it. The heat can destroy plastic components, ruin surface finishes, and warp the hinge leaves, leading to premature failure.

Part 5: Common Failure Modes & Troubleshooting

Understanding why hinges fail helps in selecting the right one and performing preventative maintenance.

Diagnosing Door Sag and Stiffness

- Problem: The door sags and is difficult to close.

- Likely Cause: Pin/Bushing Wear. This is the most common failure mode, usually caused by high cycle counts or overloading. The hole elongates, and the pin diameter decreases, creating play.

- Solution: Select a hinge with a higher load rating or one with hardened steel pins and bushings for better wear resistance.

- Problem: Rust streaks are visible, and the hinge movement is stiff.

- Likely Cause: Corrosion. This indicates the wrong material or finish was chosen for the environment.

- Solution: For washdown/corrosive environments, you must upgrade to stainless steel. For standard environments, however, ensure the black oxide or plated finish is intact.

Addressing Deformation and Looseness

- Problem: The hinge is visibly bent or deformed.

- Likely Cause: Overloading or Impact. The door is too heavy, or it was hit by an external force (like a forklift).

- Solution: First, re-calculate load requirements (including dynamic forces) and then upgrade to a more robust, heavy-duty hinge.

- Problem: The hinge feels loose at the mounting point.

- Likely Cause: Loose Fasteners. Vibration has caused the mounting screws to back out.

- Solution: Implement a regular maintenance schedule to check and tighten fasteners. Furthermore, use thread-locking compound or locking nuts during initial installation.

Part 6: Advice for Parts Wholesalers – Stocking for Success

For parts wholesalers, a smart inventory strategy is crucial. Since you can’t stock everything, it’s best to focus on what sells.

The 80/20 Rule of Hinges

Focus your inventory on the 20% of products that satisfy 80% of your customers’ needs.

- Core Stock (The 80%):

- Plastic Butt Hinges: Stock these, especially in sizes common for electrical cabinets and safety guards. They are lightweight, insulating, and your top volume seller.

- Zinc Alloy Butt Hinges: Also carry these in standard industrial sizes (e.g., 50mm, 75mm lengths). These are the versatile, cost-effective choice for general machinery.

- Fasteners: Finally, stock the corresponding screw sizes for your top-selling hinges.

- Specialty Stock (The 20%):

- Stainless Steel Butt Hinges: Keep a limited stock of common sizes for customers in the food, pharma, or marine industries.

- Torque or Detent Hinges: These are higher-margin, problem-solving products. Stocking a few popular models can make you a hero to an engineer with a specific need.

Sell a Solution, Not Just a Hinge

Train your sales staff to ask the right questions. Instead of “What hinge do you need?”, they should be asking “What are you trying to do?”. For example, if a customer needs a door to stay open, suggest a torque hinge. When they need to remove a door for cleaning, offer a lift-off hinge. And if someone is building an electrical cabinet, recommend an insulated plastic hinge and sell it as a complete kit with the matching handle and lock. By providing solutions, you become a valuable partner, not just a supplier.

Conclusion: A Small Component with a Big Impact

An industrial hinge is far more than a simple pivot point. In reality, it is a critical component that impacts a machine’s safety, usability, and long-term reliability. For machine builders, choosing the right hinge is an investment in quality and user satisfaction. Similarly, for wholesalers, understanding the different types and their applications allows you to stock smarter and sell more effectively.

By moving beyond the basic butt hinge and considering the full range of specialized options, you can build better machines and a more profitable business.

Ready to find the perfect hinge solution for your next project? Contact us today for a full catalog, technical specifications, or expert selection advice.