Vertical Form Fill Seal (VFFS) machines are a cornerstone of the modern packaging machinery industry. These fully automated packaging systems streamline the packaging process by forming, filling, and sealing bags in a vertical orientation. They are indispensable for food packaging machines, pharmaceuticals, agriculture, and consumer goods, thanks to their unmatched speed, versatility, and efficiency.

Whether integrated with a multihead weigher, an auger filler, or downstream conveyor systems, a VFFS packaging machine ensures seamless, high-speed operation. In this comprehensive overview, we’ll cover their history, working principles, components, advantages, and diverse applications across industries.

🕰️ A Brief History of VFFS Technology

The origins of the VFFS machine date back to 1936, when Walter Zwoyer of the Henry Heide Candy Company patented the first vertical form-fill-seal system. This invention marked a turning point for industrial packaging equipment, transforming what was once manual and labor-intensive into a continuous, automated packaging process.

- Early generations: purely mechanical, reliant on cams and gears.

- 1970s onward: the rise of PLC (programmable logic controller) controls enhanced precision.

- Today: modern VFFS systems feature servo motors, advanced sensors, and touch-screen HMIs, seamlessly integrating with automated packaging systems for unmatched productivity.

⚙️ How VFFS Packaging Machines Work: Step-by-Step

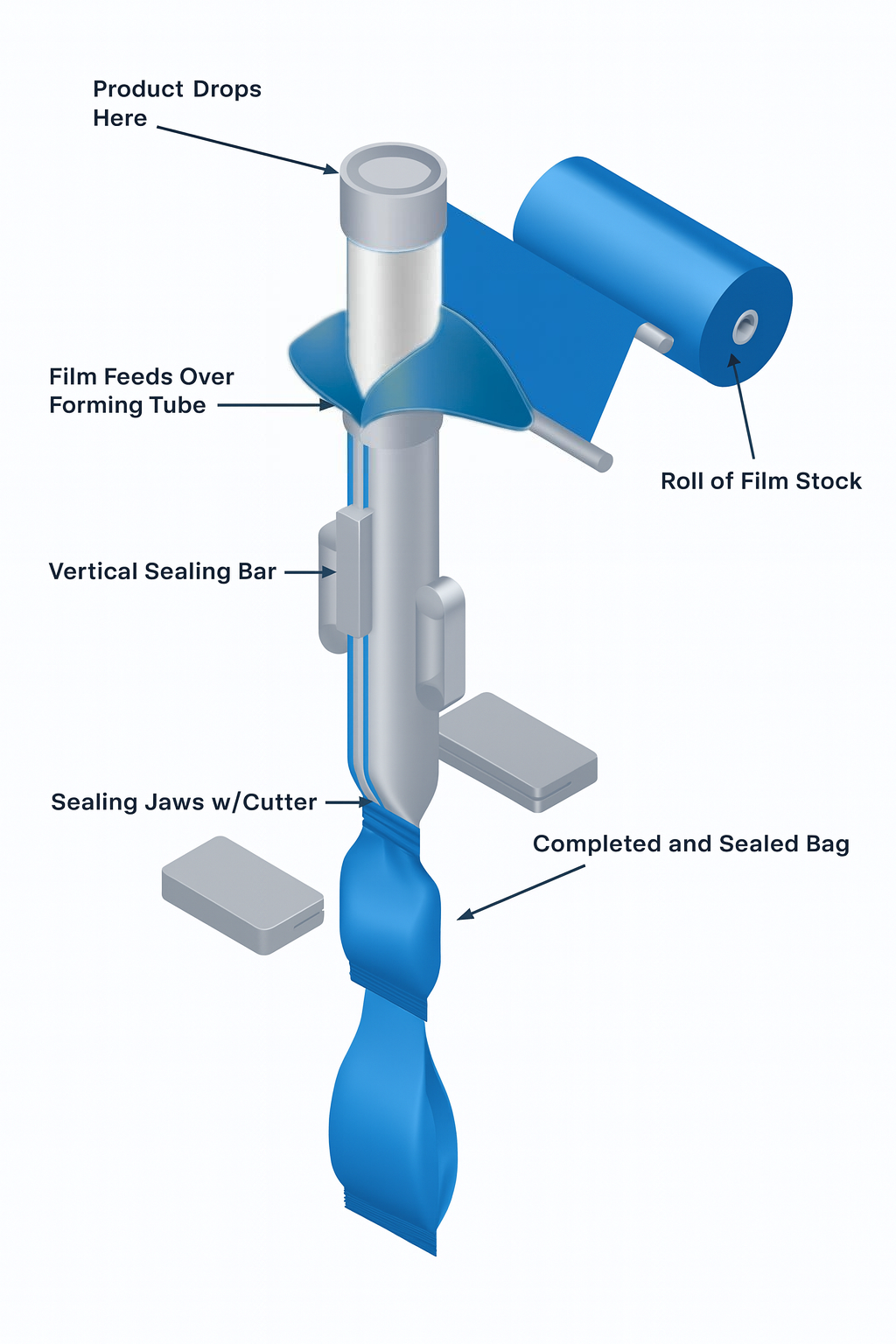

Despite variations among manufacturers, the core operating sequence is universal. Here’s how a VFFS packaging machine works:

1. Film Transport and Unwinding

- Film roll (polyethylene, laminate, or foil) is mounted on a spindle.

- Pull-down belts and rollers guide the film into the system.

- A dancer arm maintains constant tension to ensure smooth film flow.

2. Film Tracking and Positioning

- Registration marks ensure accurate alignment for bag cutting.

- Optional printers add dates, logos, or barcodes.

- Photo-eyes and sensors maintain film edge alignment.

3. Bag Forming

- The film passes over a forming tube, wrapping around it.

- Vertical sealing jaws create the bag’s longitudinal seam.

- Options include fin seal or lap seal, depending on packaging needs.

4. Bag Filling & Sealing

- Multihead weighers (for solids), auger fillers (for powders), or liquid fillers dispense product.

- Bottom seals are created, product is filled, then top seals close the bag.

- A cutting knife separates filled bags for discharge.

5. Bag Discharge

- Finished bags exit the system onto conveyor systems, often feeding into secondary industrial packaging equipment like cartoners, case packers, or palletizers.

- High-speed VFFS units can produce up to 300 bags per minute.

🚀 The Advantages of VFFS Machines

1. High Efficiency & Speed

Automating forming, filling, and sealing minimizes labor, reduces errors, and supports large-scale production.

2. Versatility

Handles powders, granules, liquids, and solids. Compatible with varied bag styles (pillow packs, gusseted bags, block-bottom pouches, and stick packs).

3. Cost-Effectiveness

Reduces manual labor costs and film waste. Higher throughput equals better ROI.

4. Product Integrity

Airtight seals protect against contaminants, extend shelf life, and ensure compliance for food and pharma packaging. Nitrogen flushing enhances freshness.

5. Sustainability

Modern VFFS packaging machines use only the required amount of film and consume less energy, supporting eco-friendly operations.

🏭 Applications of VFFS Packaging Machines

Because of their flexibility, VFFS machines are used across many industries:

- Food & Beverage: coffee, tea, sugar, spices, chips, sauces, frozen vegetables.

- Pharmaceuticals: powders, tablets, and capsules in sterile packs.

- Consumer Goods: detergents, sachet packaging machines for single-use products, pet food.

- Agriculture: seeds, fertilizers, and animal feed.

When integrated with multihead weighers, auger fillers, and conveyor systems, VFFS machines form the backbone of fully automated packaging systems.

🔑 VFFS vs. Sachet Packaging Machines

While both machines form, fill, and seal, they differ in scale and application:

| Feature | VFFS Packaging Machine | Sachet Packaging Machine |

|---|---|---|

| Speed | High (up to 300 bags/min) | Lower (ideal for small packs) |

| Bag Types | Pillow, gusset, block-bottom | Stick packs, single-use sachets |

| Industries | Food, pharma, consumer goods, agriculture | Pharma samples, condiments, personal care |

| Integration | Works with multihead weighers, auger fillers, conveyors | Often standalone, sometimes inline |

📈 Future Trends in VFFS Technology

- Smart automation: IoT-enabled monitoring and predictive maintenance.

- AI-driven adjustments: real-time optimization of sealing and filling parameters.

- Sustainable films: compostable or recyclable materials for eco-friendly packaging.

- Compact footprints: smaller, more efficient VFFS units for limited factory space.

🧾 Bottom Line

The VFFS packaging machine is not just another piece of industrial packaging equipment—it’s a core driver of efficiency, safety, and scalability in modern manufacturing. From snacks to pharmaceuticals, its adaptability makes it a must-have in automated packaging systems worldwide.

When paired with multihead weighers, sachet packaging machines, and conveyor systems, VFFS technology creates a powerful, fully integrated packaging solution.

📌 FAQs About VFFS Machines

Q1: What does VFFS stand for?

A: Vertical Form Fill Seal—machines that form bags from film, fill them, and seal them in one continuous process.

Q2: Can VFFS machines handle liquids?

A: Yes. Special sealing jaws and filling nozzles allow packaging of sauces, oils, and beverages.

Q3: What’s the difference between VFFS and sachet packaging machines?

A: VFFS handles larger bags and higher throughput, while sachet machines are specialized for small single-use packs.

Q4: How fast can a VFFS packaging machine run?

A: Depending on model, up to 300 bags per minute.

Q5: Which fillers integrate with VFFS machines?

A: Multihead weighers (snacks, frozen foods), auger fillers (powders), piston fillers (liquids).

Q6: Are VFFS machines suitable for eco-friendly packaging films?

A: Yes. Many new models are compatible with recyclable and compostable films.

Q7: What industries rely most on VFFS technology?

A: Food, pharma, agriculture, and consumer goods.

Q8: How much does a VFFS machine cost?

A: Pricing depends on speed, size, and features. Contact a packaging machinery supplier for a tailored quote.