For any food processor handling fresh meat, marinated poultry, or oily prepared foods, the packaging stage is often the biggest bottleneck in production.

You know the scenario: The production line is running smoothly until the product hits the weighing scale. Suddenly, trouble starts. Meat chunks stick to the vibration pans, feeding becomes intermittent, and the product even gets stuck completely. Weighing accuracy drops, forcing you to stop the machine frequently for cleaning—or worse, revert to inefficient manual weighing.

Many machine importers and factory managers mistakenly assume that “a multihead weigher is a standard multihead weigher.” However, attempting to use standard vibration-based equipment to handle sticky products is often the root cause of inefficiency.

In this guide, we will explain why standard weighers fail with sticky materials and how Screw Feeder Technology provides a precise weighing solution for sticky food.

What Are “Difficult-to-Handle” Products?

Before discussing the solution, we need to define the problem. In the weighing industry, “difficult-to-flow” doesn’t just mean “wet.” We are referring to materials with high viscosity or high surface friction that prevents them from sliding naturally.

Common examples include:

- Fresh Meat & Poultry: Chicken breast, beef cubes, and pork strips. These are naturally moist and have high surface friction.

- Marinated & Seasoned Foods: Meat or vegetables coated in thick sauces, oil, or honey glazes.

- Oily Seafood: Small fish or shrimp that tend to clump together.

- Prepared Meals: Sticky fried rice, wet noodles, or cut vegetables with high moisture content.

For these products, the two forces standard multihead weighers rely on—gravity and vibration—are usually ineffective.

Why Standard Multihead Weighers Struggle

To understand the solution, you must first understand why the traditional method fails.

A standard multihead weigher uses a vibrating Top Cone and Linear Feeder Pans to move product from the inlet to the weigh hoppers. It relies on the product bouncing lightly and sliding downward.

However, when you apply vibration to sticky products like fresh chicken, the opposite happens: The vibration acts as a compactor.

Instead of pushing the material forward, the vibrational energy causes sticky products to adhere more tightly to the pans. The meat sits still, absorbing the energy, until it finally accumulates into a large clump and falls into the hopper.

This leads to two major issues:

Empty Hoppers: The system waits for product that won’t move, causing a significant drop in speed (CPM).

Overweight / High Giveaway: When the product finally moves, it falls in large masses. The machine is forced to combine these heavy buckets, resulting in overweight packages and raw material waste.

In summary, The mechanism of vibration feeding simply does not provide enough kinetic force to move sticky items effectively.

The Paradox of Feeding Control vs. Weighing Accuracy

There is a golden rule in automated weighing: If you cannot control the feeding, you cannot guarantee the accuracy.

The “brain” (CPU) of a multihead weigher needs a variety of distinct, moderate weights to calculate the best combination. If the linear feeder pans cannot deliver precise, uniform product to the weigh hoppers, the CPU has no good data to calculate with.

For difficult-to-flow products, the battle for accuracy is not won at the “weighing” stage, but at the “feeding” stage.

Screw Feeding: The Practical Solution

Since vibration doesn’t work for sticky objects, we must change the physics of movement. This is where the screw feeder multihead weigher comes in.

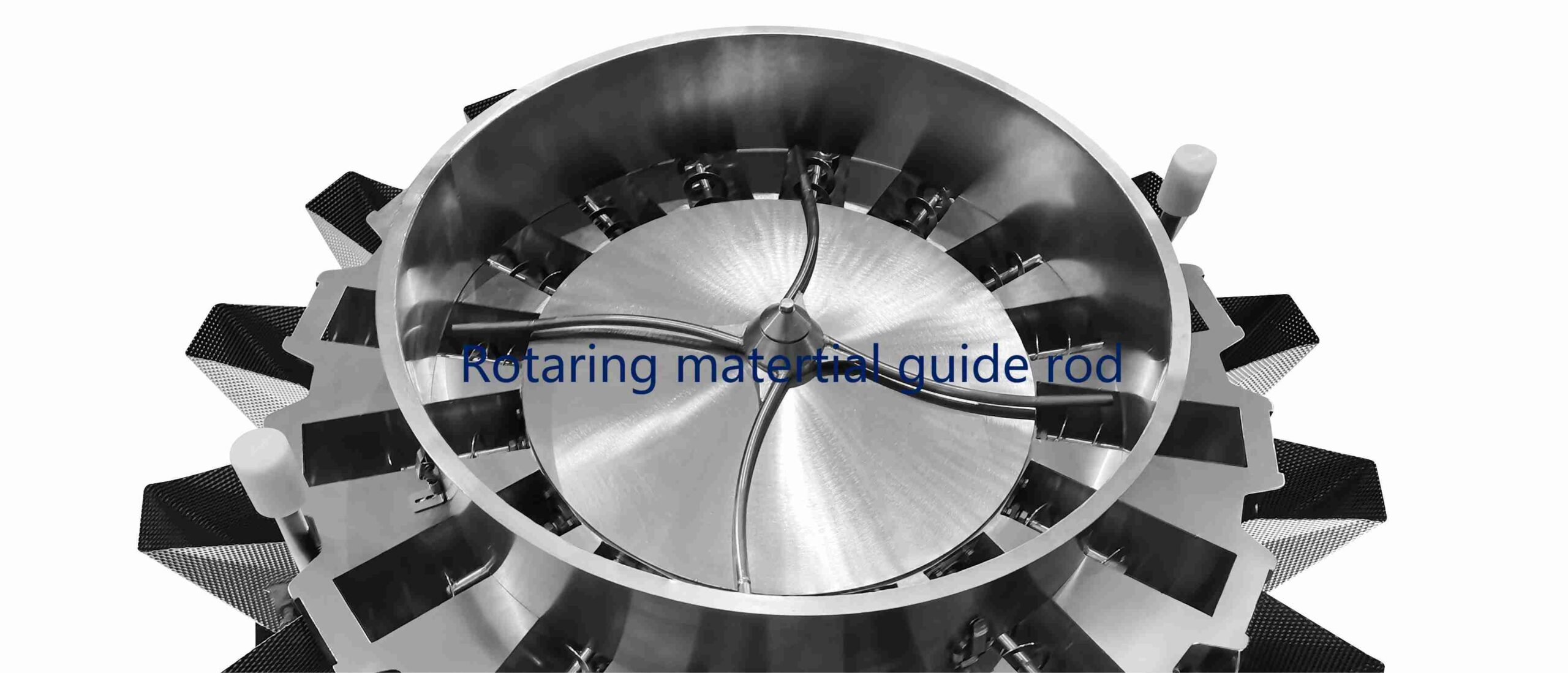

Unlike standard machines, this system abandons vibration pans and replaces them with rotating stainless steel screws (spirals).

How It Works

The screw does not rely on vibration. Instead, it uses mechanical rotation to push the material forward forcibly. This is a transport method that is both powerful and controllable.

Forceful Pushing: It overcomes the viscosity and friction of meat or sauces mechanically.

Precise Control: The machine can precisely control the number of rotations. If the weigh hopper needs a tiny amount of product, the screw turns slightly; if it needs a large amount, it rotates more.

Core Benefits for Processors

Eliminate Sticking: The rotating action shears the product away from the feeder, preventing buildup.

Consistent Flow: Regardless of how sticky the marinade is, the screw ensures the product actually reaches the weigh buckets.

Automate “Impossible” Products: It allows factories to automate packaging for products that previously could only be handled by hand (such as sticky kimchi or oily diced meat).

Conclusion

Choosing the right equipment is about matching technology to product characteristics. While standard vibration weighers are perfect for dry, free-flowing goods like snacks and grains, they are not designed to fight the physics of wet, sticky food.

For fresh meat, poultry, and marinated delicacies, switching to a screw feeder multihead weigher is often the difference between owning a high-efficiency production line and being trapped in a maintenance nightmare.

Ready to automate your sticky product weighing? Say goodbye to clogging and downtime. Explore our [Screw Feeder Multihead Weigher Series] to see detailed specifications, or contact our engineering team today for a customized layout drawing for your factory.