Mid-Autumn Festival: A Celebration of Reunion

Every year, when the moon shines at its fullest in September, families across China gather to celebrate the Mid-Autumn Festival. It’s a time of reunion, gratitude, and storytelling. At the heart of the festival is the mooncake—round, golden, and rich in flavor. Beyond being a festive treat, mooncakes symbolize unity and completeness, carrying centuries of cultural heritage and the warmth of family ties.

From offerings to the moon in ancient dynasties to today’s beautifully packaged gifts exchanged between relatives, friends, and business partners, mooncakes have evolved into more than food. They are a cultural bond, a sweet expression of love, remembrance, and togetherness.

From Handcrafted Workshops to Smart Factories: A Grand Transformation

Behind every mooncake lies a complex journey. In traditional workshops, everything—from kneading the dough to preparing fillings, wrapping, and pressing molds—relied heavily on the skill and experience of master artisans. While handmade mooncakes remain cherished for their authenticity, growing demand has pushed the industry to evolve.

Today, automated package machines and modern production lines have revolutionized mooncake manufacturing. Precision, speed, and consistency have become the new standards, allowing brands to deliver not just quantity but also uncompromising quality.

Saying Goodbye to Manual Complexity, Embracing Precision

In a modern food production line, automation touches every corner of the process. Tasks that once required dozens of workers are now handled smoothly by specialized equipment.

1. Standardized Dough and Filling Preparation

The secret to a delicious mooncake lies in the perfect balance between crust and filling. In the past, achieving this relied on the craftsman’s hands and years of experience. Now, advanced double-shaft mixers guarantee even blending of lotus seed paste, red bean paste, or nut fillings. Automated dough kneaders replicate the pressure and rhythm of hand-kneading, ensuring elastic, silky dough every time.

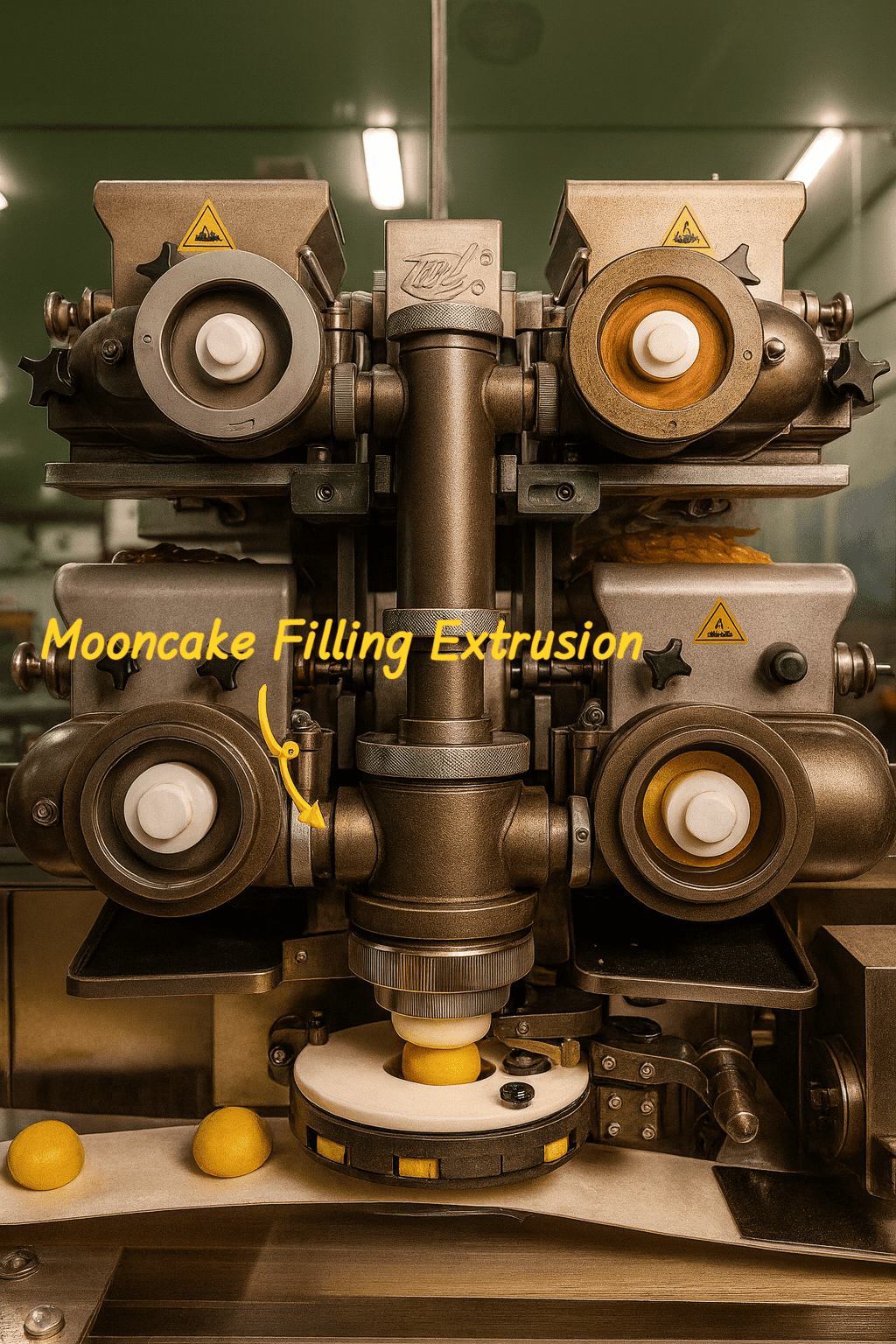

2. Accurate Portioning with Automatic Filling

“Thin crust, generous filling” has always been the golden rule of mooncakes. In manual production, this balance was achieved by feel. Today, an automatic mooncake filling machine calculates the exact ratio of dough and filling, extruding them with high accuracy. From there, the food conveyor system transfers the semi-finished mooncakes seamlessly to shaping stations, ensuring speed and consistency.

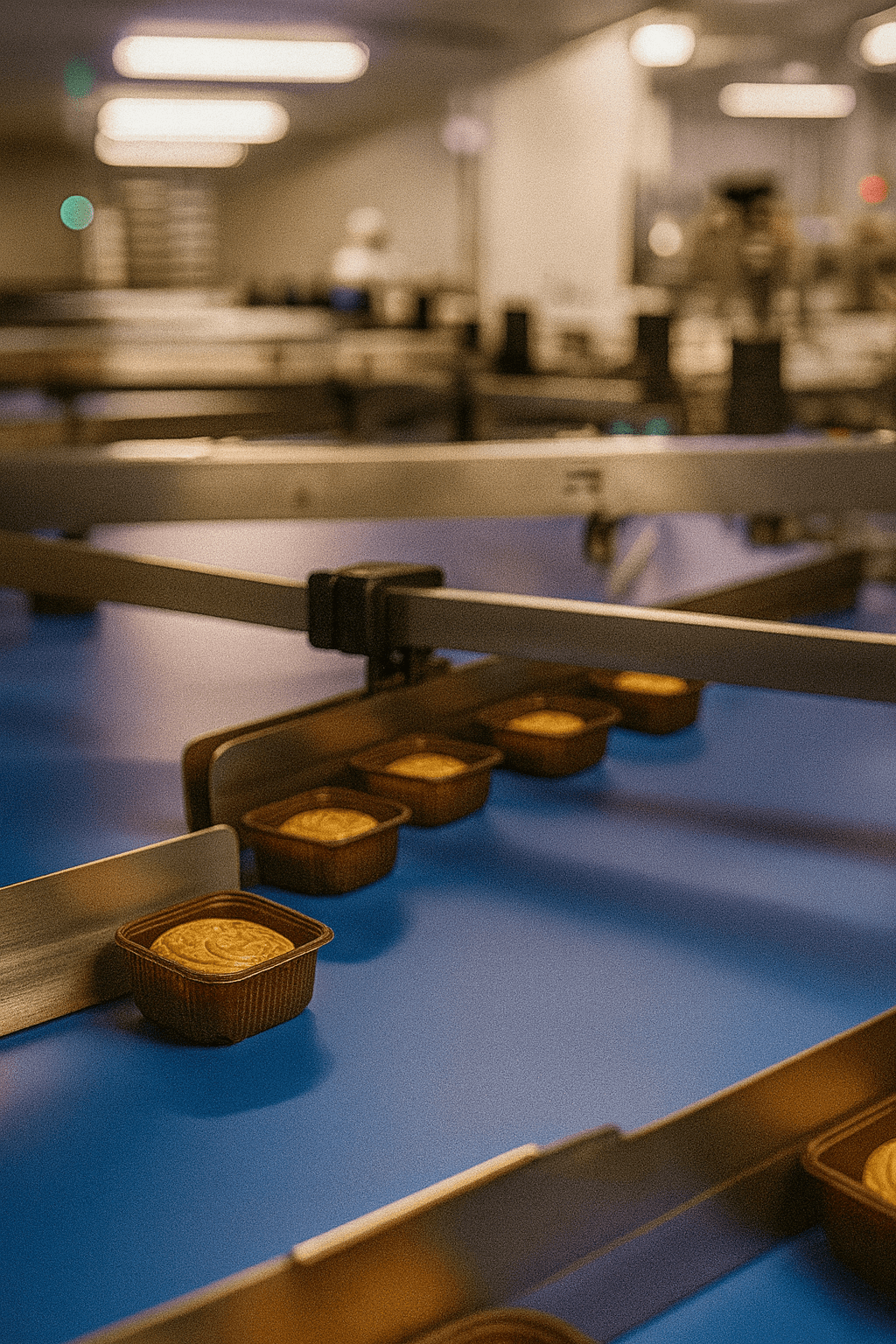

3. From Baking to Packaging in One Flow

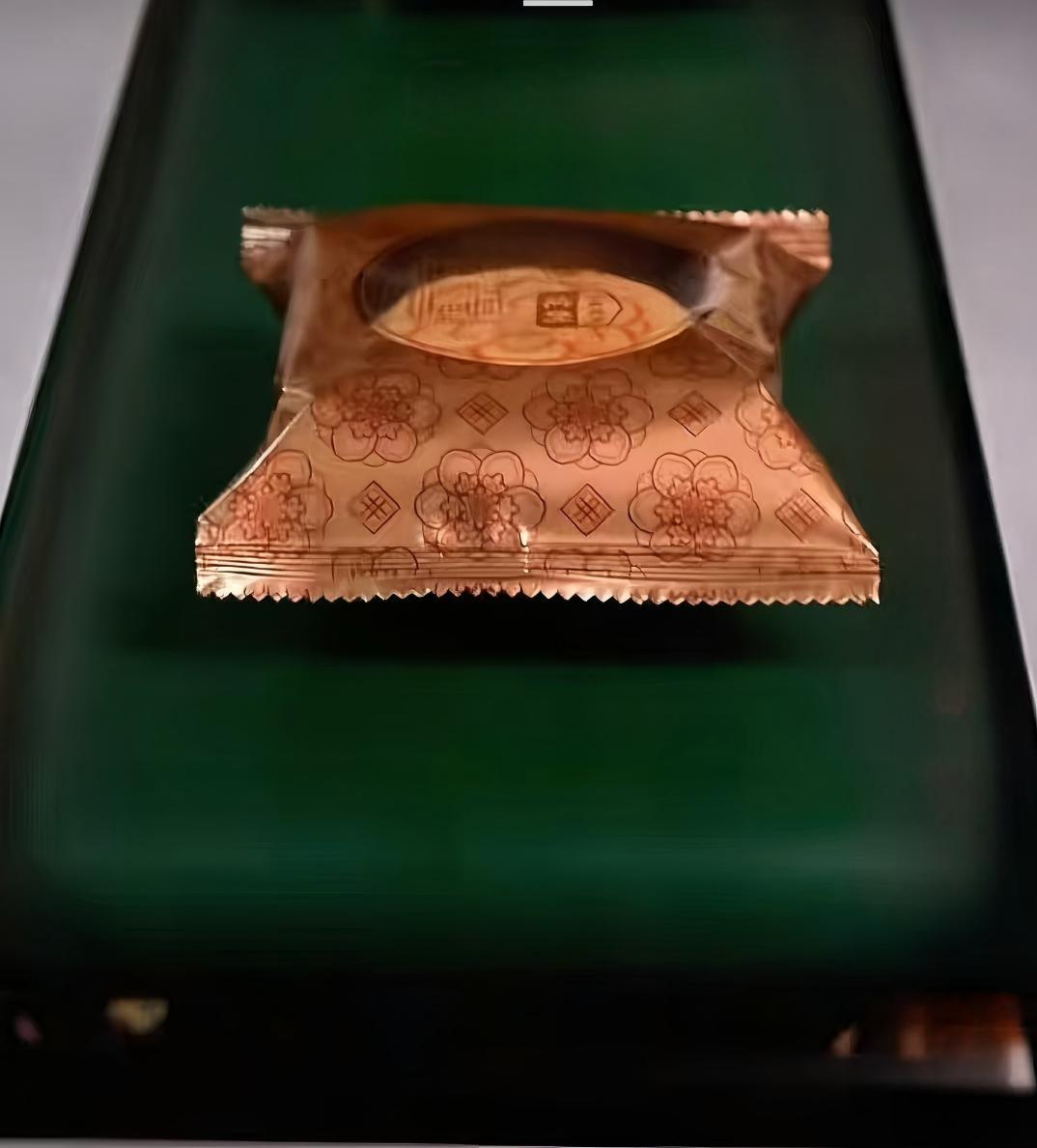

Shaped mooncakes travel via spiral cooling towers and food conveyors into long tunnel ovens. Here, temperature and humidity are precisely controlled, ensuring an even bake and the signature golden crust. After cooling, mooncakes are automatically guided to high-speed flow wrappers. These packaging machines for mooncakes wrap each product securely, preserving freshness and enhancing presentation—perfect for gifting.

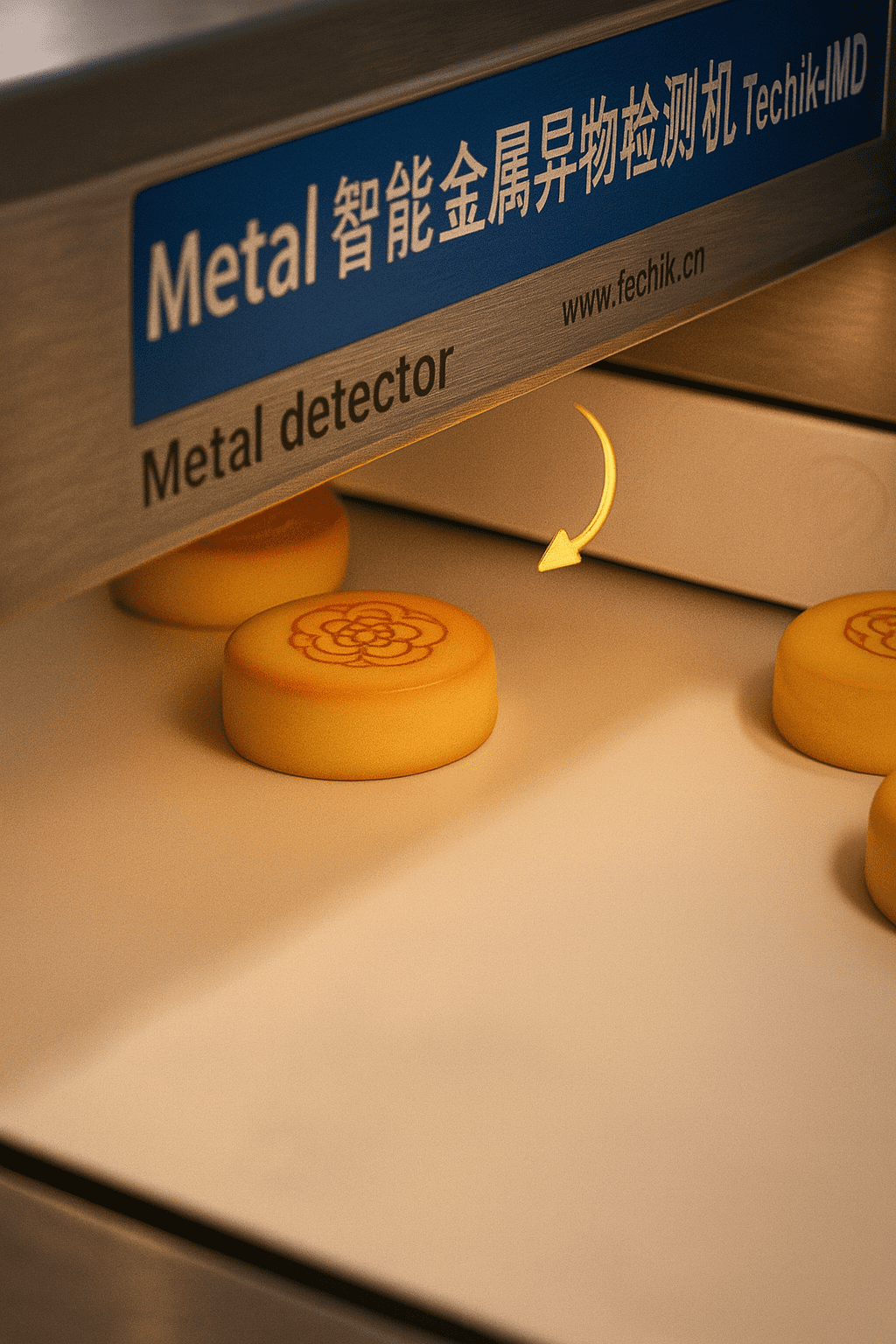

4. Quality Control: The Final Guard

Even with automation, quality is never compromised. Advanced sensors and checkweighers inspect every packaged mooncake. Vision systems verify sealing integrity, while manual spot-checks by trained staff add an extra layer of assurance. This seamless collaboration between humans and smart food machinery-style precision systems ensures that every mooncake reaching customers is safe, fresh, and beautiful.

Beyond Efficiency: The Value of Automation

The automation revolution in mooncake production is not just about speed:

Efficiency Boost: One line equipped with automatic package machines and multihead weighers can achieve 60–120 packs per minute—three times faster than manual packaging.

Cost Savings: By reducing reliance on labor, companies cut up to 40% in operating costs while maintaining consistent quality.

Brand Value: Uniform appearance, strong seals, and premium packaging for mooncakes elevate brand image and consumer trust.

Worker Well-Being: Machines handle repetitive, heavy tasks, freeing staff to focus on innovation, product development, and quality improvement.

Technology Empowers Tradition

When tradition meets technology, something beautiful happens. Automated mooncake package machines don’t erase the cultural meaning of mooncakes—they preserve it. By ensuring every cake is consistent, hygienic, and attractively packed, automation helps brands meet massive seasonal demand without losing the heart of the tradition.

At Fill Package, we specialize in food conveyors, flow wrapper systems, and packaging machines designed for mooncakes and other festive treats. Whether you’re a growing bakery or an established food brand, we provide smart, reliable solutions that let you honor tradition while stepping confidently into the future.

✨ What do you think about the future of mooncake production? Would you prefer handmade authenticity or smart, automated efficiency? Share your thoughts in the comments—we’d love to hear from you!