High Quality Food Metal Detector

Make sure your products only have right formulations

Conveyor Metal Detector

Conveyor metal detector is an tunnel metal detector installed on the conveyor belt. It is used to detect and remove any type of contamination form production. It is mainly used in the source of the production line or after the finished product packaging. The machine includes three parts: Feed area -Conveyor belt,Detect area – tunnel metal detector, remove area-pusher or air jet.

No matter how careful your process is, metal impurities in the product are always happen, such as: metals worn off the equipment surface, small screws loosened form machines, small pieces of the machine or accidentally dropped when maintenance , these damage not only the machine but also your customers and your brand .

Our metal detector for food industrial reliably detect and separate metal-containing bag in each package during continuous operation on fast belts. Metal detection can be integrated without problems into your existing production lines., simple and reliable operation in low maintenance costs. with high sensitivity and detection level, our conveyor belt metal detectors are design for customers’ requirements and budget, If you have any questions, contact us now.

Types Of Metal Detectors

Our goal is to ensure there are only correct ingredients in your food,Here are several tunnel type metal detectors for your reference ,for more requirement ,contact us.

Benefits In Details

Color touch screen with fast response, simple and easy operation.Intelligent self-learning technology ,parameters can be set automatically.

German high-speed Load Cell ,FPGA hardware filter with intelligent algorithms, excellent speed and accuracy.

Good detection of stability performance ,with Ultra-fast dynamic weight tracking and automatic compensation technology

Use 304 sanitary stainless steel frame ,Stable design by stainless steel structure meets the sanitary requirements ,simple and nice .

How Do Conveyor Metal Detector Work?

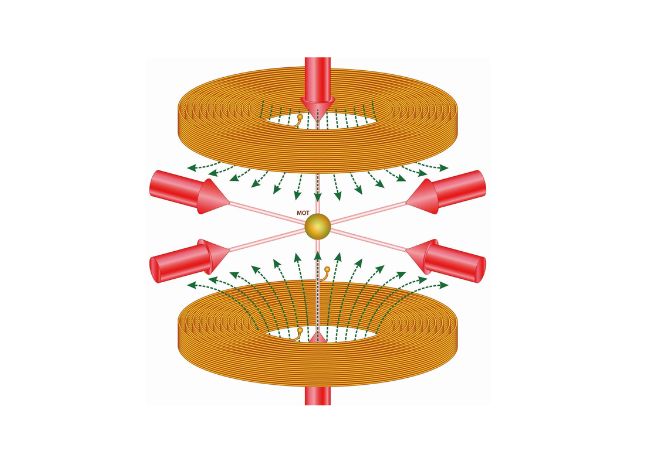

Conveyor belt metal detector working principle is electromagnetic induction. Each metal detection is composed of one or more inductance coils. The electromagnetic field generated by them during operation attracts or repels the metals in the product. The magnetic field generated by the coil surrounds the In the opening area of the metal detector for conveyor belt, when a product with metal passes through the magnetic field of metal detection, the metal generates an eddy current and coil received it. This signal will be sent to conveyor metal detector and an alarm signal be send out.

Metal detector for food industrial also uses the same working principle and uses the conductivity of the most common metal to provide accurate and reliable detection.

What Metal Can Be Found By Food Metal Detector?

Food metal detectors can detect three major types of metal pollutants: ferrous metals, non-ferrous metals and stainless steel. The detection depends on the electrical conductivity and magnetic permeability of metal pollutants. Ferrous metals also named steel materials, such as cast iron, low carbon steel, etc. Contains iron, which is magnetic and conductive, and is easily detected. Non-ferrous metals include aluminum, copper, nickel, tin, brass and zinc, which are not magnetic, but they are good conductors. However ,stainless steel is the most difficult to detect because they are non-magnetic and a poor conduction. The sensitivity or detection depend on specific composition of stainless steel . When the product contains water or high salt, stainless steel can not be detected better. If there are others such as glass ,calcified bone ,ceramics ,stones etc , X-ray inspection system is the primary choice.

Industrial Metal Detector Application

Almost all food and drinks whose packaging materials do not contain any metal are suitable for inspection with food metal detectors, such as snack food, fruit, bakery food, frozen food, rice, meat, seafood, etc. That is to say, most of the food packaging is inline metal detectors can be used for security detection. Different packaging materials have different blet metal detectors.For example, for packaging products containing metal foil, products packaged in metal containers or metal inserts, Standard metal detector for food industrial are not suitable, we recommend to use special detection for aluminum foil packaging.Due to x-ray inspection systems do not rely on conductivity and magnetic fields during inspection, so x-ray inspection systems are the preferred method of inspecting products packaged with metal components.

Metal Detector Test Standards

The reliability of detection performance is very important for industrial metal detector . Each of our metal detection has been tested continuously to ensure that the performance of each is superior. In the customer’s application, the performance of the machine is obvious Superior to most competitors, our engineers have spent a lot of time developing and testing practices both in appearance design and internal procedures.

The sensitivity is another important factors for industrial metal detectors. It’s the ability of metal detectors to locate for each metal contaminant. In food production, metals are usually from every stage of the production process We have different awareness contaminants can be balanced against the occurrence of false positives, and the sensitivity of food metal detector can be improved through testing and fine-tuning.

In food production and package , Metal detector for food industrial can detect ferrous metals, non-ferrous metals and stainless steel. As a low-density, high-conductivity non-ferrous metal, aluminum usually exists in the form of small pieces and aluminum foil in food.Due to Its good conductivity, food metal detectors can detect aluminum smaller than other metals, and X-ray inspection cannot detect aluminum of the same size, so using metal detectors for food industry is the best way to detect aluminum.

The food metal detector is suitable for the food production and packaging to prevent metal pollutants was falled into the food. It can detect for raw materials or finished products with package . For packaged products, Food metal detector can be placed at the back of the packaging machine,for raw materials, metal detectors for food industrial are placed in the front of machine,Prevent damage to equipment,delay productionand high maintenance costs.

Generally, there is no problem with our industrial metal detectors being used for more than 15-20 years, but no matter what the equipments,we recommend that you point out your use environment and work requirements for reproduction, because the work environment and use habits are crucial to the life of the machine.

Both food metal detectors and x-rays can be used to check for foreign objects in food production. The difference between them is the method of detecting contamination. Metal detection uses electrical conductivity to locate contamination in products. it can detect ferrous metals, non-ferrous metals and stainless steel.X-ray inspection uses the difference in density between the product and the foreign object, it can provide a wider range of material detection, besides metals, it can also detect plastics, glass, stones, etc.

The product effect is the natural conductivity of the product itself and its impact on the food metal detection, that mean even if there is no metal contamination in the product, the product effect can be observed because the food metal detector uses conductivity The rate is used to check for pollutants, so conductive products will trigger the metal detector when they pass through the metal detector, such as products containing salt and high water . If the product effect is too high, it will have a bad influence on the test results.

The metal detection in the food industry is generally the same speed as the production lines. The specific speed will be different depending on the product. The conveyor metal detector can run at more than 100 meters per minute, However ,the pipeline and free flaw metal detector are only limited by the speed when the product passes through them.