What Is Flow Wrap Packaing ?

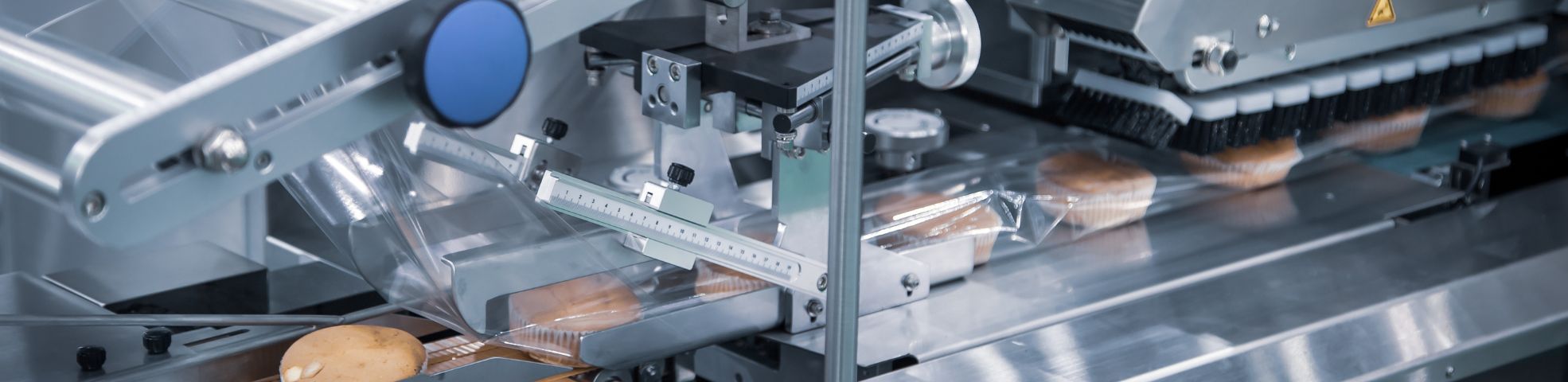

We can understand from the letters of it. Flow and wrap horizontally

Horizontal :Products go in to infeed conveyor horizontally

Flow :Flow into certain space

Wrapper : Wrap the film around it ,sealing and discharging the products to finish conveyor.

The whole process is automated and no need request manual operation ,fast speed and high protection.

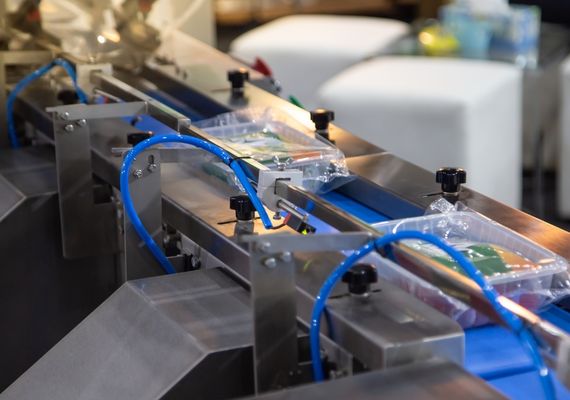

Horizontal flow wrappers also called flow wrap machine ,flow pack ,horizontal flow wrap machine,It’s usually used in the packaging of a single product, and trays package . widely used in a variety of industries including food, personal care, household items and so on .

Our Flow Wrap Machines (3)

Our flow wrap machines 3 classification methods:

According to the sealing method of the knife holder: rotary knife holder and go &back knife holder.

According to body material, divided into stainless steel flow wrapper and carben steel flow wrapper.

According to direction of the film, divided into up-moving type and down-moving type.

Your Benefits With Our Flow Wrappers

Make a tight ,reliable wrap within short time,max speed up to 230 bags/min.

Econmocial and safe packaging,widely used in many products .

Recyclable materials to reduce environmental pollution, sustainable packaging.

Made according to customers request .improve production capacity mmore effectively .

Flow Wrap Machine Working Principle

Firstly,Your products be deliveried by conveyor into film box , Film will be wrapped with products tightly form right to left or left to right and seal it .Then ,be sealed and cutted horizontaly .Finally products will delivery to finish conveyor for next package and shipment.

Why Should Use Flow Pack?

Flow wrappers can help you Increase production, reduce staffs input, provide you with a stable packaging solution to protect the product from contamination, improve your quality of packaging.Easy and fast to exchange size.monther board store multiple pack specifications .

Big income with small investment ,Flow wrap machine price is quite attractive ,can help you recover cost within a few months ,some high salary place even 1-2 months.

How flow wrapper installation and operation?

Each flow wrapper is unique to meet all your production requirement.So firstly , Pls offer the size and status of the products, capacity requirements and film requirements to us . Our team will test these with same material or similar material .and manufacture Horizontal flow wrappers after pass and confirmation.installation and use videos sent to you before flock wrapper shipment. and its operation is very simple and friendly .you can get it in short time. If you feel necessary, we can also visit you to finish installation and training.

Fill&Package Flow Wrapper Advantage

Focusing on the package industry for more than 10 years .let you use satisfy package machines as our goal .Entry-level carbon steel chassis and high-end stainless steel chassis for your choose .

General program,similar to the program of most Flow Wrappers in China. It doesn’t take time to relearn, saving installation and after-sales time

Horizontal Flow Wrapper Applications

Many candy and chocolate used this simple and fast packaging .

Lost cost and extremely flexible.deeply loved by mask manufacturers

The most common packaging for chili, cabbage, and bamboo, etc. environmentally friendly and convenient.

Related Product

People also ask

Maybe you will have many questions to purchase flow wrapper .pls check follows ,Hope helpful to you .

Standard powder require : 220VAC ,3 phase ,50/60Hz .also can be customized .

Machine need 6 bar and 80 PSI minimum .

Maximum speed :250 bags per minute .exactly .it should be depended on material measurement .

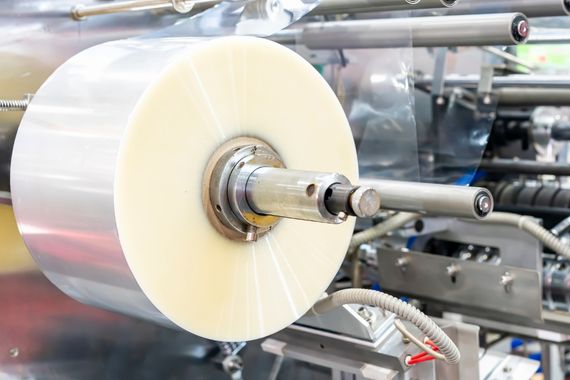

Usually ,film diameter :400mm ,maximun weigh :35kgs ,maximum width :650mm .

It included : name ,model ,serial number ,Powder .production time .this wrapper ID …..also can have customer logo if necessary .