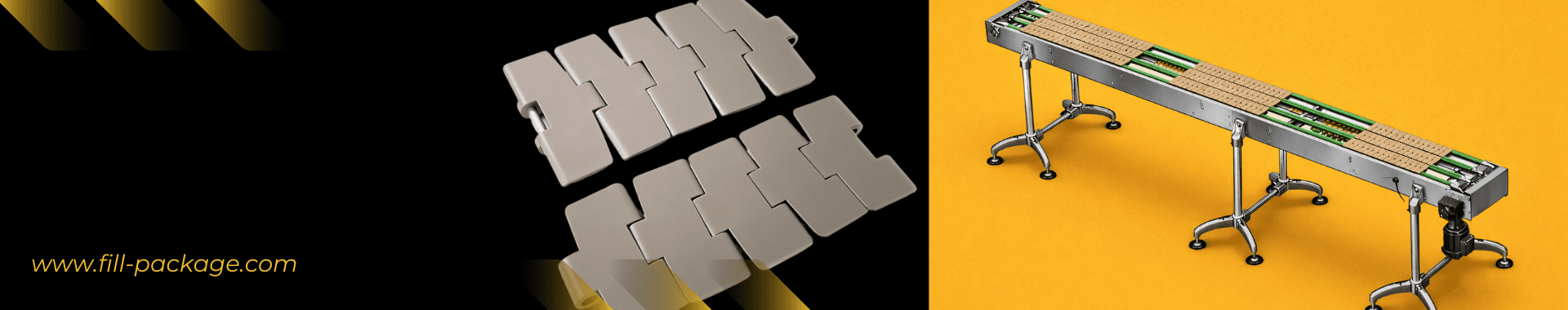

Stainless Steel Flat Top Chains

Engineered for extreme durability, our stainless steel flat top chains provide unmatched performance in high-temperature, corrosive, and heavy-load packaging applications. Explore our straight-running and side-flexing series to find the ideal solution for your demanding production environment.

Introduction: The Ultimate Solution for Demanding Conveying Environments

Key Advantages of Stainless Steel Flat Top Chains

Unmatched Durability and Strength

Superior High-Temperature Resistance

- Pasteurization tunnels

- Sterilization processes

- Hot-fill bottling lines

- Ovens and cooling tunnels

Excellent Corrosion and Chemical Resistance

Our Stainless Steel Flat Top Chain Series

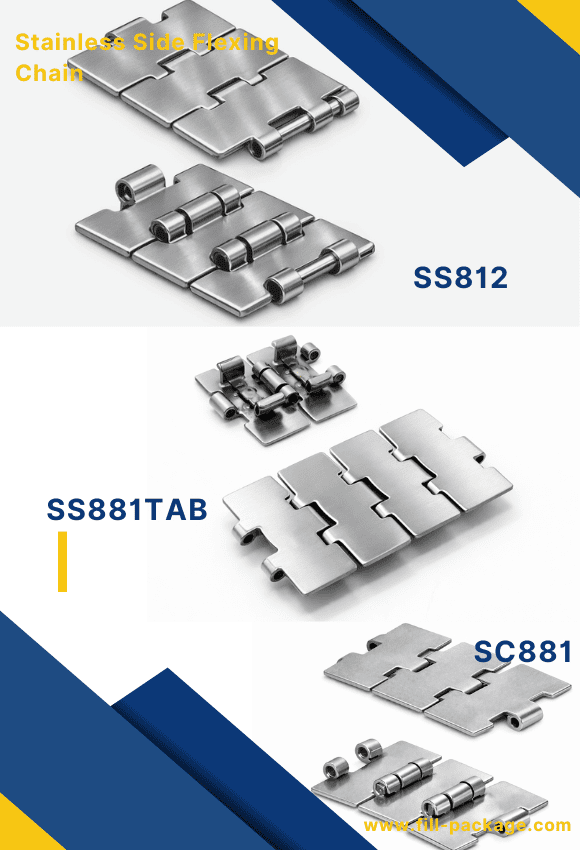

SS812 Series: Straight-Running Steel Table Top Chain

- Best For: General-purpose, straight-line conveying in demanding environments.

- Key Feature: A robust and reliable workhorse for applications where turning is not required.

- Widths Available: 63.5mm (2.5″) to 190.5mm (7.5″)

SS881TAB & SS881 Series: Side-Flexing Turning Chains

- Best For: Complex conveyor layouts that require curves and turns.

- Key Feature: Allows for continuous product flow around obstacles, eliminating the need for separate transfer conveyors.

- Minimum Turning Radius: 500mm to 700mm, depending on the series.

SC881 Series: Side-Flexing Chain without Guide Tabs

- Best For: Flexible layouts where a smooth chain edge is preferred.

- Key Feature: Provides the same turning capability as the SS881 series but without the side guide tabs, offering a more streamlined profile.

Technical Specifications at a Glance

Feature | SS812 Series | SS881TAB / SS881 / SC881 Series |

Function | Straight-Running | Side-Flexing (Turning) |

Pitch | 38.1mm (1.5″) | 38.1mm (1.5″) |

Material Options | SUS304, SUS202 | SUS304, SUS202 |

Tensile Load | Up to 5,600 N | Up to 5,600 N |

Temperature Range | -20°C to 120°C | -20°C to 120°C |

Typical Widths | 63.5mm – 190.5mm | 82.6mm – 304.8mm |

Minimum Turning Radius | N/A | 500mm – 700mm |

Material Combinations for Optimal Performance

Combination | Main Body | Pin | Key Benefit |

Standard | SUS304 | SUS304 | Excellent corrosion resistance for general food & beverage applications. |

Hardened | SUS420 | SUS202 | Higher hardness and wear resistance for more abrasive environments. |

Hybrid | SUS304 | SUS202 | A balanced combination of corrosion resistance and strength. |

Matching Sprockets for a Complete System

- JS812 Series: For SS812 straight-running chains.

- JS881 / JI881 Series: For SS881 and SC881 side-flexing chains.

Typical Applications for Stainless Steel Flat Top Chains

- Beverage Production: Conveying glass bottles through pasteurizers and filling lines.

- Food Processing: Moving cans and jars through cooking and cooling tunnels.

- Pharmaceutical Manufacturing: Ensuring sterile and hygienic transfer of vials and containers.

- Industrial Conveying: Handling heavy or abrasive parts in manufacturing environments.

How to Choose the Right Stainless Steel Flat Top Chain

- Determine the Path: Do you need a straight-running chain (SS812) or a side-flexing chain for curves (SS881/SC881)?

- Select the Width: Choose a chain width that provides adequate support for your product’s base.

- Choose the Material: Select the stainless steel combination (e.g., SUS304, SUS420) that best matches your temperature, corrosion, and wear requirements.

- Confirm Sprockets: Ensure you have the correct matching sprockets for your chosen chain series.

Related Product

Stainless steel flat top chains offer three critical advantages that plastic chains cannot match. First, they excel in high-temperature environments, operating reliably from -20°C to 120°C, making them ideal for pasteurization tunnels and hot-fill lines. Second, their inherent corrosion resistance ensures they can withstand harsh chemical washdowns and acidic products without degrading. Third, they provide superior strength and durability, with tensile loads up to 5,600 N, making them the preferred choice for conveying heavy glass bottles, multi-packs, and other substantial products.

Our high temperature flat top chains are designed to operate in a wide temperature range of -20°C to 120°C (-4°F to 248°F). This makes them suitable for extreme applications such as pasteurization tunnels, sterilization processes, hot-fill bottling lines, ovens, and cooling tunnels. The stainless steel construction maintains its structural integrity and performance even under these demanding thermal conditions.

The choice depends on your specific application requirements:

- SUS304: Best for general food and beverage applications where excellent corrosion resistance is the priority. It offers superior resistance to acidic products and chemical washdowns, making it the standard choice for most packaging lines.

- SUS420: Recommended for more abrasive environments where higher hardness and wear resistance are required. It is slightly less corrosion-resistant than SUS304 but provides better durability under heavy mechanical stress.

Yes. We offer side-flexing stainless steel flat top chains specifically designed for turning applications. Our SS881TAB, SS881, and SC881 series can navigate curves with a minimum turning radius of 500mm to 700mm, depending on the chain width and series. This allows you to create complex conveyor layouts without needing separate transfer conveyors, maintaining continuous product flow around obstacles and through tight spaces.

Absolutely. Our stainless steel flat top chains are specifically engineered for industries with stringent hygiene requirements, including food, beverage, and pharmaceutical manufacturing. The stainless steel construction (SUS304 or SUS420) is inherently resistant to bacteria growth and can withstand the aggressive cleaning agents and high-temperature washdown procedures required in these industries. They are the ideal choice when product safety and regulatory compliance are paramount.

- SUS420 body + SUS202 pin: Up to 4,000 N

- SUS304 body + SUS304 pin: Up to 5,000 N

- SUS304 body + SUS202 pin: Up to 5,600 N

- JS812 Series: For SS812 straight-running chains

- JS881 / JI881 Series: For SS881 and SC881 side-flexing chains

The choice depends on your conveyor layout:

- Straight-Running (SS812 Series): Choose this if your conveyor line is entirely straight with no curves. It is the most cost-effective option for simple layouts.

- Side-Flexing (SS881TAB, SS881, SC881 Series): Choose this if your conveyor line needs to navigate curves, go around obstacles, or create a compact layout. Side-flexing chains eliminate the need for separate transfer conveyors and maintain continuous product flow through turns.

- Beverage Production: Conveying glass bottles through pasteurizers, fillers, and cappers.

- Food Processing: Moving cans and jars through cooking, cooling, and sterilization tunnels.

- Pharmaceutical Manufacturing: Ensuring sterile transfer of vials, ampoules, and containers.

- Industrial Conveying: Handling heavy or abrasive parts in manufacturing environments.

- Application Details: What products are you conveying? (e.g., bottles, cans, jars)

- Operating Environment: Temperature range, exposure to chemicals or moisture.

- Conveyor Layout: Straight-running or turning? If turning, what is the minimum radius?

- Chain Width: What width do you require to support your products?

- Material Preference: Do you have a preference for SUS304 or SUS420?